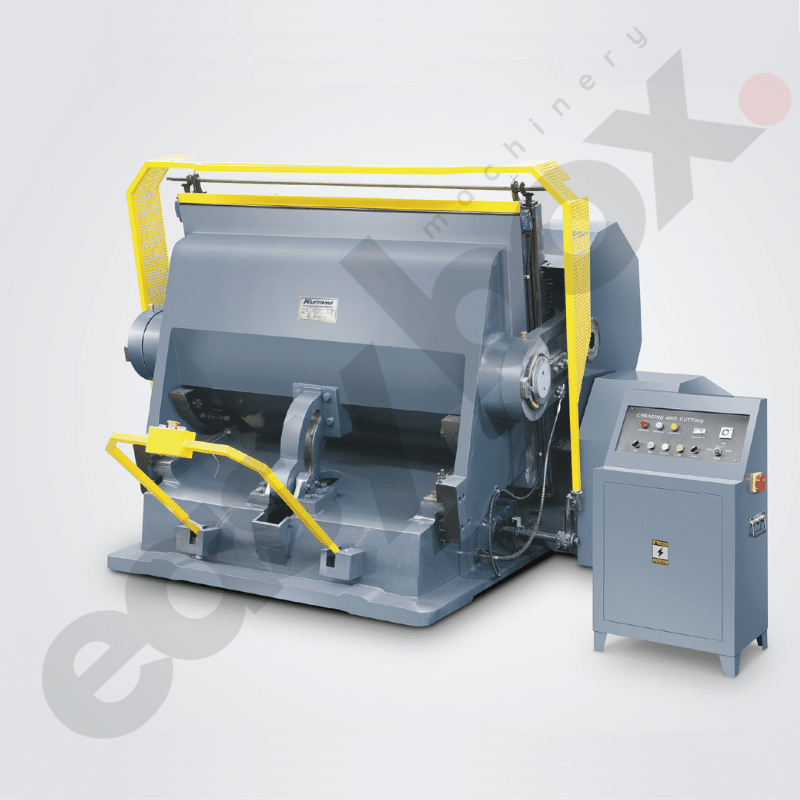

ML 1600/1800/2000/2200 Creasing And Die Cutting Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

Introduction to the ML 1600/1800/2000/2200 Creasing and Die Cutting Machine

The ML 1600/1800/2000/2200 Creasing and Die Cutting Machine is a versatile and reliable solution designed to meet the high demands of the packaging, printing, and decoration industries. This advanced machine excels in handling various materials such as cardboards, corrugated boards, plastic sheets, and leather products, making it an essential tool for businesses aiming to enhance their production capabilities.

Product Description

The ML series, with models 1600, 1800, 2000, and 2200, is a specialized equipment designed for creasing and die-cutting all assortments of common cardboards, corrugated boards, plastic sheets, and leather products. It is ideal for applications in printing, packaging, decoration, and plastic industries. The machine is renowned for its firm structure, exquisite craftsmanship, superior cutting performance, high precision, ease of operation, and robust safety and reliability features.

Key Features

High-Quality Construction

The ML series is constructed using high-quality materials and high-tension casting, ensuring durability and long-term reliability. This robust build makes the machine a valuable investment for businesses seeking to improve their production efficiency.

Four-Shaft Bevel Wheel Structure

These machines adopt a four-shaft bevel wheel structure, providing steady operation, excellent cutting performance, and low noise. This advanced design ensures precise and efficient cutting, meeting the high standards required in modern manufacturing.

Sound Structural Design

The height layout and gear angle of the frame are meticulously designed for optimal performance. This thoughtful design contributes to the machine’s stability and precision during operation.

Advanced Electrical System

The electrical system of the ML series is designed according to IEC standards, ensuring safe and reliable operation. Compliance with these international standards highlights the machine’s quality and safety features.

Versatile Functions

The ML series offers three distinct functions: single slitting, successive slitting, and time delay. The scope of these functions can be easily adjusted to meet specific production needs, providing flexibility and versatility in various applications.

Reliable Safety Protection System

Equipped with a reliable safety protection system, the ML series ensures operator safety during use. This feature is crucial for preventing accidents and maintaining a safe working environment.

Concentrated Lubricating System

The machines include a concentrated lubricating system that ensures smooth and efficient operation. This system minimizes wear and tear on moving parts, extending the lifespan of the machine and reducing maintenance costs.

Applications

The ML 1600/1800/2000/2200 Creasing and Die Cutting Machines are perfect for a wide range of applications, including:

- Cardboard Processing: Ideal for cutting and creasing various types of cardboard.

- Corrugated Board Processing: Suitable for handling corrugated boards with precision.

- Plastic Sheet Cutting: Efficiently processes plastic sheets for various applications.

- Leather Product Cutting: Perfect for creating detailed and precise cuts in leather products.

Industry Impact

By integrating advanced technology and robust construction, the ML series sets a new standard in the printing, packaging, and decoration industries. These machines help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Conclusion

The ML 1600/1800/2000/2200 Creasing and Die Cutting Machines represent a significant advancement in cutting and creasing technology. With their precision, versatility, and robust construction, these machines are designed to meet the diverse needs of modern manufacturing. Investing in the ML series means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

Additional information

| Model | PYQ401C |

|---|---|

| Inner Chase Size | 750×520mm |

| Speed | 25 |

| Max. Rule Length | <15m |

| Motor Power | 2.2kw |

| Machine Weight | 2000kg |

| Packing(Overall) Dimensions | 1650×1400×1500mm |

Reviews

There are no reviews yet.