MHC 1100BC/1300BC/1500BC/1650BC Semi-Automatic Die Cutting And Creasing Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

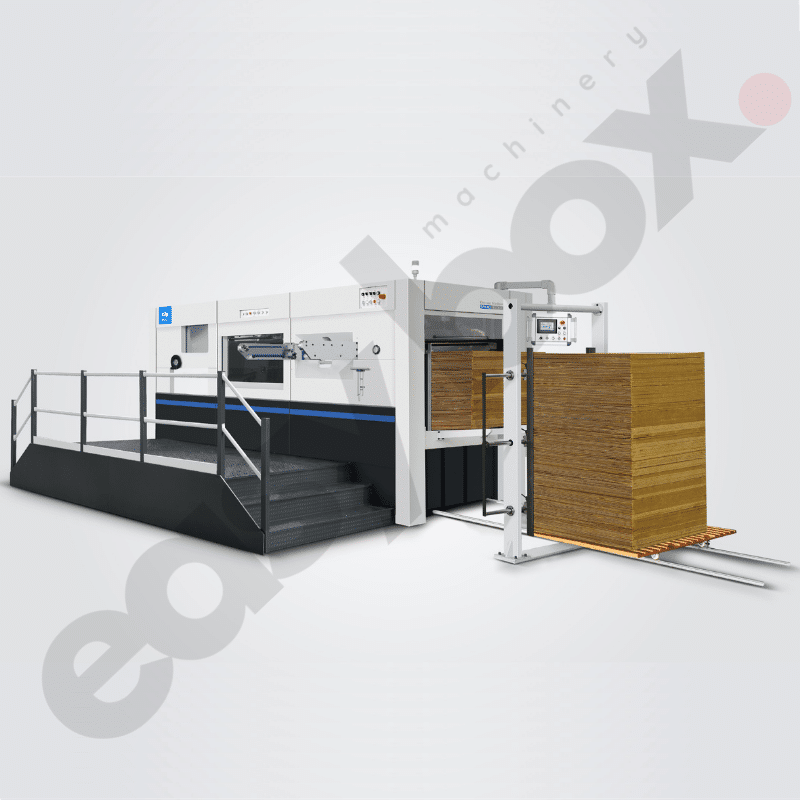

Introduction to the MHC 1100BC/1300BC/1500BC/1650BC Semi-Automatic Die Cutting and Creasing Machine

The MHC 1100BC/1300BC/1500BC/1650BC Semi-Automatic Die Cutting and Creasing Machine is an advanced solution designed to meet the specific needs of the packaging and printing industries. This machine combines precision, efficiency, and user-friendly operation, ensuring high performance and reliability for various production environments.

Key Features

High Precision and Accuracy

The MHC BC series delivers millimeter-perfect die cutting and creasing, making it ideal for applications requiring detailed and exact specifications. This high level of precision reduces material waste and ensures superior product quality, which is essential for maintaining high production standards.

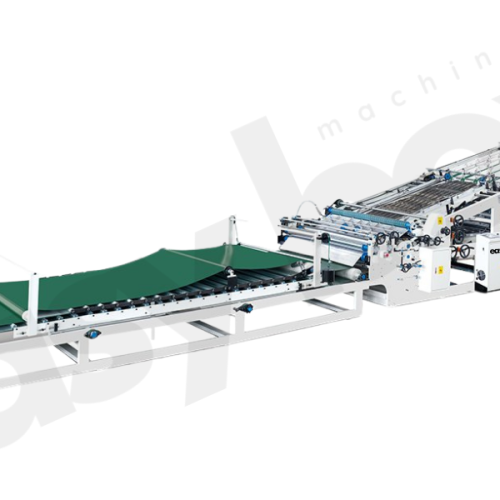

Semi-Automatic Operation

The semi-automatic operation of the MHC BC series provides a balance between automation and manual control, offering flexibility and ease of use. This feature is particularly beneficial for small to medium-sized production runs where full automation may not be necessary.

Robust Performance

Engineered for durability, the MHC BC series is built with robust materials and advanced technology to withstand intensive use. Its construction guarantees long-term reliability and consistent performance, even under demanding production conditions.

Integrated Stripping Function

The MHC BC series includes an integrated stripping function that automatically removes waste material from the finished product. This ensures clean and precise edges, reduces manual labor, and speeds up the production process, leading to significant labor cost savings.

User-Friendly Interface

An intuitive control panel provides easy setup and operation. This user-friendly interface minimizes the learning curve for operators, ensuring smooth and efficient operation.

Benefits

- Enhanced Efficiency: The semi-automatic operation combined with high precision and robust performance streamlines the production process, reducing downtime and labor costs.

- Improved Safety: Equipped with safety features such as emergency stop buttons and protective guards, the MHC BC series ensures a safe working environment, adhering to the highest industry standards.

- Cost-Effective: Ideal for businesses seeking a cost-effective solution without sacrificing quality or performance. The MHC BC series provides excellent value by enhancing productivity and maintaining high-quality output.

Applications

The MHC 1100BC/1300BC/1500BC/1650BC series is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its precision, versatility, and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet diverse manufacturing needs.

Industry Impact

By integrating precision and semi-automatic operation, the MHC BC series Semi-Automatic Die Cutting and Creasing Machine sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Conclusion

The MHC 1100BC/1300BC/1500BC/1650BC Semi-Automatic Die Cutting and Creasing Machine represents a significant advancement in die cutting and creasing technology. With its precision, robust performance, and user-friendly operation, this machine is designed to meet the diverse needs of modern manufacturing. Investing in the MHC BC series means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

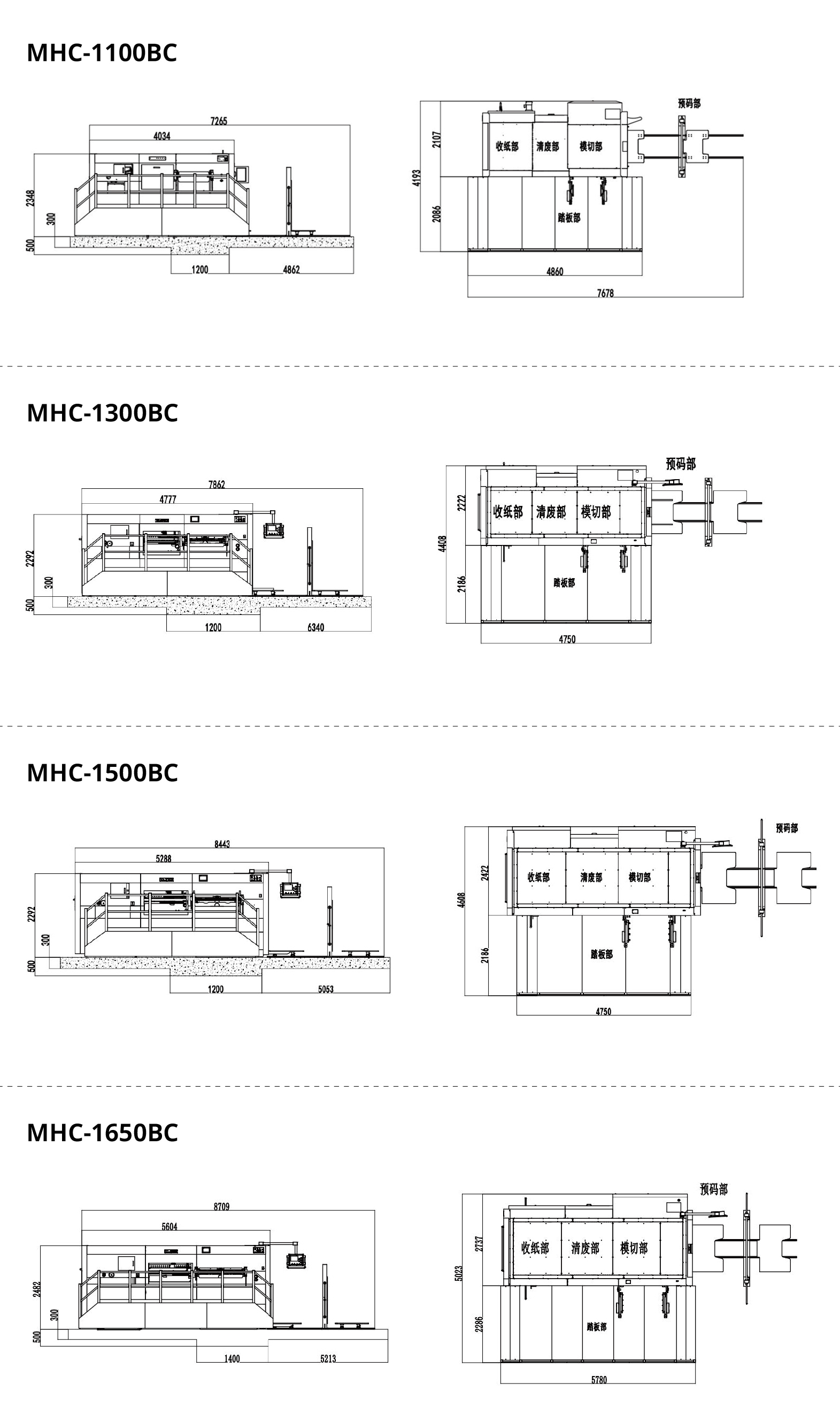

Drawing

Additional information

| Model | MHC-1100BC |

|---|---|

| Max. Paper Size | 1100×790mm |

| Min. Paper Size | 400×350mm |

| Max. Die-cutting Size | 1070×770mm |

| Max. Working Speed | 7000s/h |

| Main Motor Wattage | 11kw |

| Max. Working Pressure | 300T |

| Machine Weight | 14T |

| Overall Dimension | 7270×4200×2350mm(L: paper prepared track included,W: platform included) |

| Scope Of Application | ≤7mm corrugated paper,E, B, C, A and AB corrugated paper |

Reviews

There are no reviews yet.