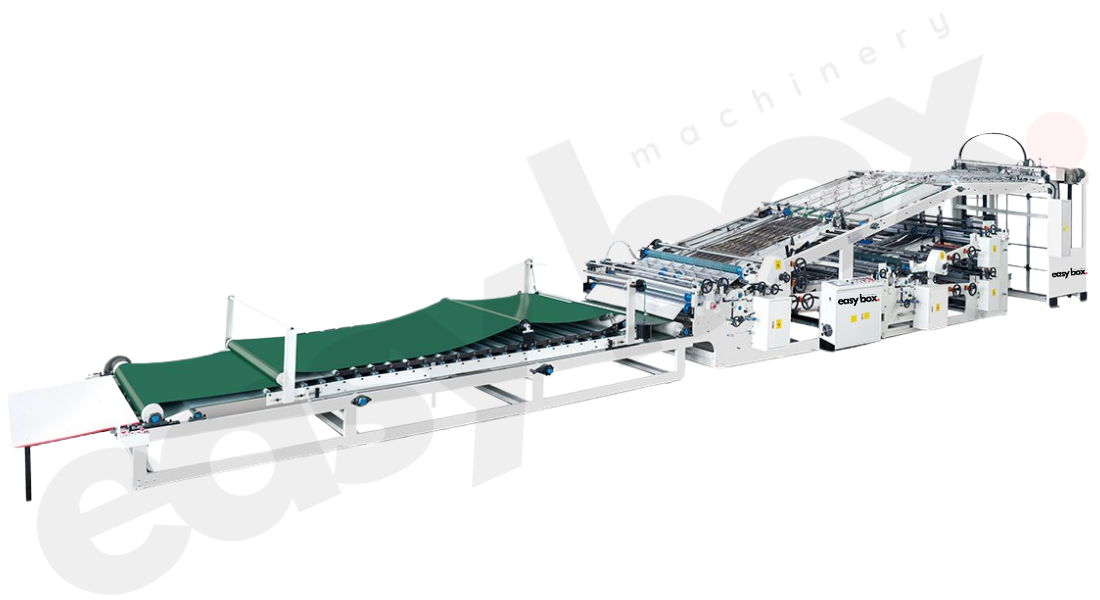

Automatic 5 Ply Flute Laminating Machine: Revolutionizing the Packaging Industry

The Automatic 5 Ply Flute Laminating Machine stands as a testament to innovation in the packaging industry, designed to meet the high demands for durability and aesthetics in packaging materials. This advanced machinery automates the process of laminating printed paper sheets with up to five layers of corrugated cardboard, ensuring products are not only well-protected but also visually appealing.

Bridging Efficiency With Quality

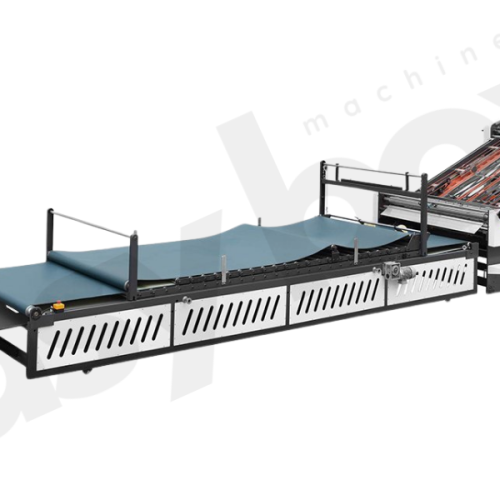

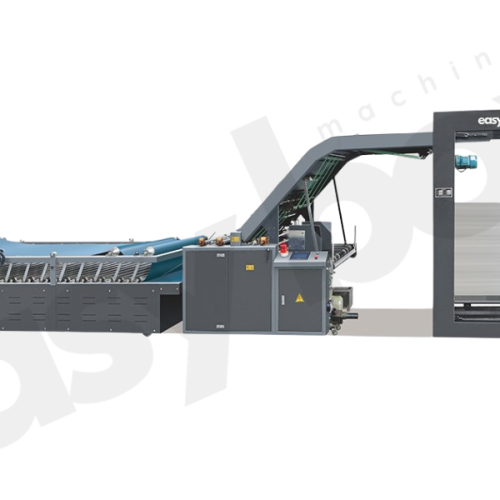

The Automatic 5 Ply Flute Laminating Machine is engineered for high-volume production, seamlessly integrating automatic feeding, alignment, gluing, and pressing processes. This integration significantly enhances production efficiency while maintaining consistent quality across all packaged goods.

Features and Benefits

- High-Speed Production: Catering to industrial-scale packaging needs, this machine boosts throughput, enabling businesses to meet their production deadlines effortlessly.

- Versatility: Capable of handling various sizes and types of printed sheets and corrugated cardboard, it offers flexibility in packaging design and customization.

- Precision Laminating: With its advanced alignment and gluing systems, it ensures flawless lamination, enhancing the structural integrity and aesthetic quality of the packaging.

- Cost-Effectiveness: By automating complex lamination processes, it reduces labor costs and minimizes waste, making it a cost-effective solution for packaging manufacturers.

Applications Across Industries

The Automatic 5 Ply Flute Laminating Machine finds its application in a wide range of industries, from electronics and food products to consumer goods. Its ability to reinforce packaging materials makes it indispensable for ensuring the safe transportation and storage of products, while its precision in laminating printed surfaces aids in effective brand communication and marketing strategies.

Conclusion

The introduction of the Automatic 5 Ply Flute Laminating Machine into the packaging industry marks a significant leap forward in production capabilities. Its combination of efficiency, versatility, and quality assurance makes it a pivotal tool for businesses looking to elevate their packaging standards. As the industry continues to evolve, this machinery will undoubtedly play a crucial role in shaping the future of packaging, offering an optimal balance between protection, aesthetics, and cost-efficiency.

Reviews

There are no reviews yet.