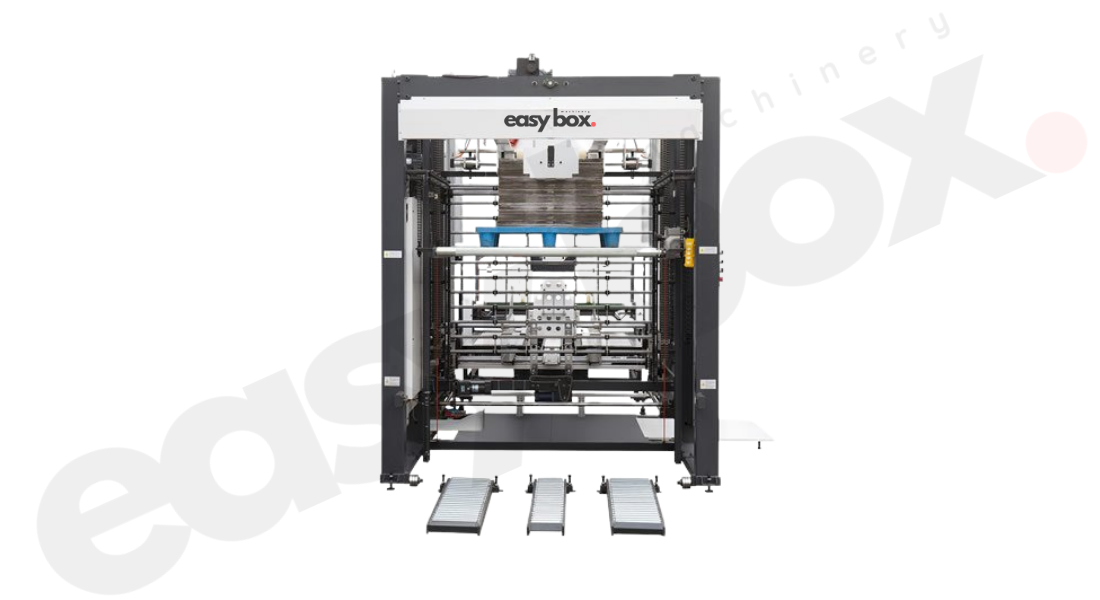

EBM-1100S-1150S Auto Pile Turner And Stacking Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

Additional information

| Product Information | Auto Pile Turner and Stacking Machine |

|---|---|

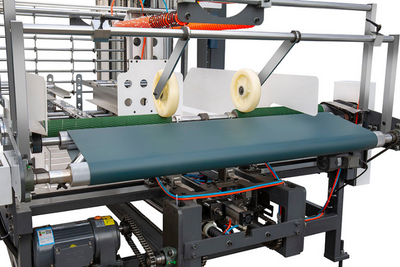

| Paper Separating System | Driving wheel and laminating press belt joint to transmit power. Laminated paper be stacked down to down pallet by driving wheel and synchronous belt, when reach the specified number, separating rod lift and separate the paper. |

| Down Push System | Driven by the cylinder two pawl forward movement, push the set up quantity paper into a turnover device |

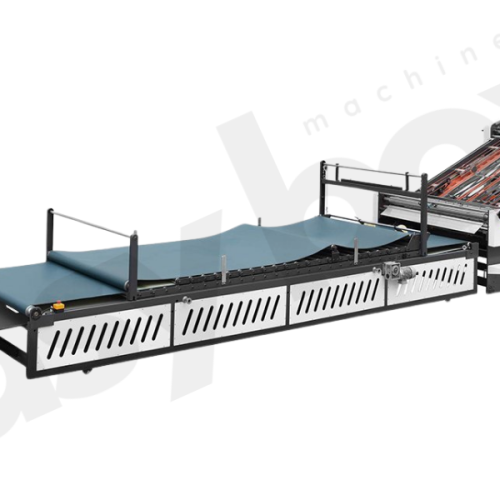

| Turning System | Using the automatic clamping system to make paper front and back alternately placed, make sure the laminated paper smooth and stiff, convenient for subsequent production line. |

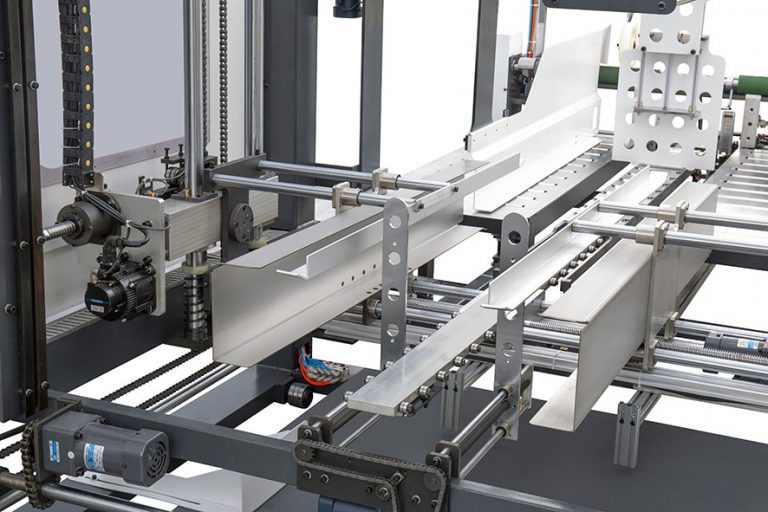

| Up Push System | Using The motor drives the chain to drive the upper push plate to move forward and backward pushing the lifting paper into collecting system and waiting to be piled |

| Piling System | Reciprocating motion of four splint patting the collected paper orderly, ensure the collecting neat |

| Collecting System | When the paper stacking to 1.7M in height, collecting platen automatic drop, hydraulic car will pull out the whole stack of paper, at the same time the vice paper collecting table automatic work, complete non-stop collecting finished |

| Electronic Unit | All parts adopt well-known brand, reasonable program design, working by one key to complete the operation, automatic fault detection. |

| Product Name | EBM-1100S-1150S Auto Pile Turner And Stacking Machine |

| Model | EBM-1100S-1150S |

| Max Sheet Size | 1450X1450 / 1650X1450 |

| Min Sheet Size | 500X500 / 500X500 |

| Machine Dimension | 6830X2760X2950 / 6830X3160X2950 |

| Weight | 3700KGS / 4000KGS |

| Power | 6KW / 6KW |

Reviews

There are no reviews yet.