BHT 1650EFC/1900EFC/2100EFC Automatic Die Cutting Machine Linkage Production Line (Down Feeder)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

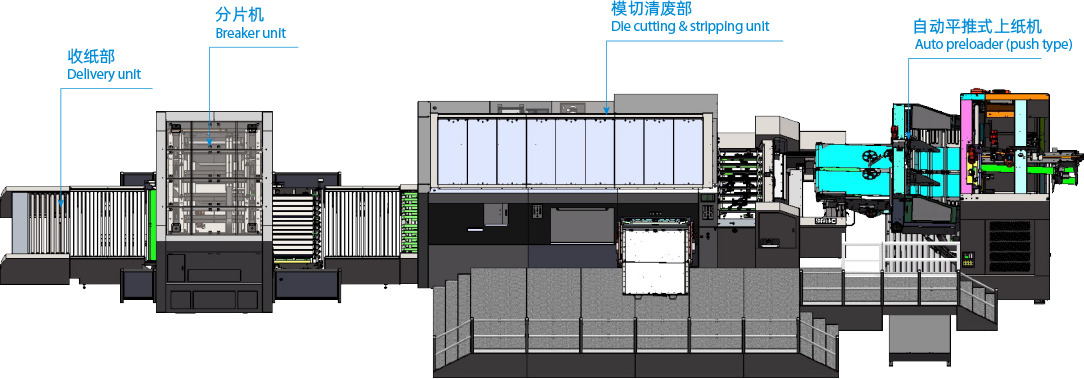

Introduction to the BHT 1650EFC/1900EFC/2100EFC Automatic Die Cutting Machine Linkage Production Line (Down Feeder)

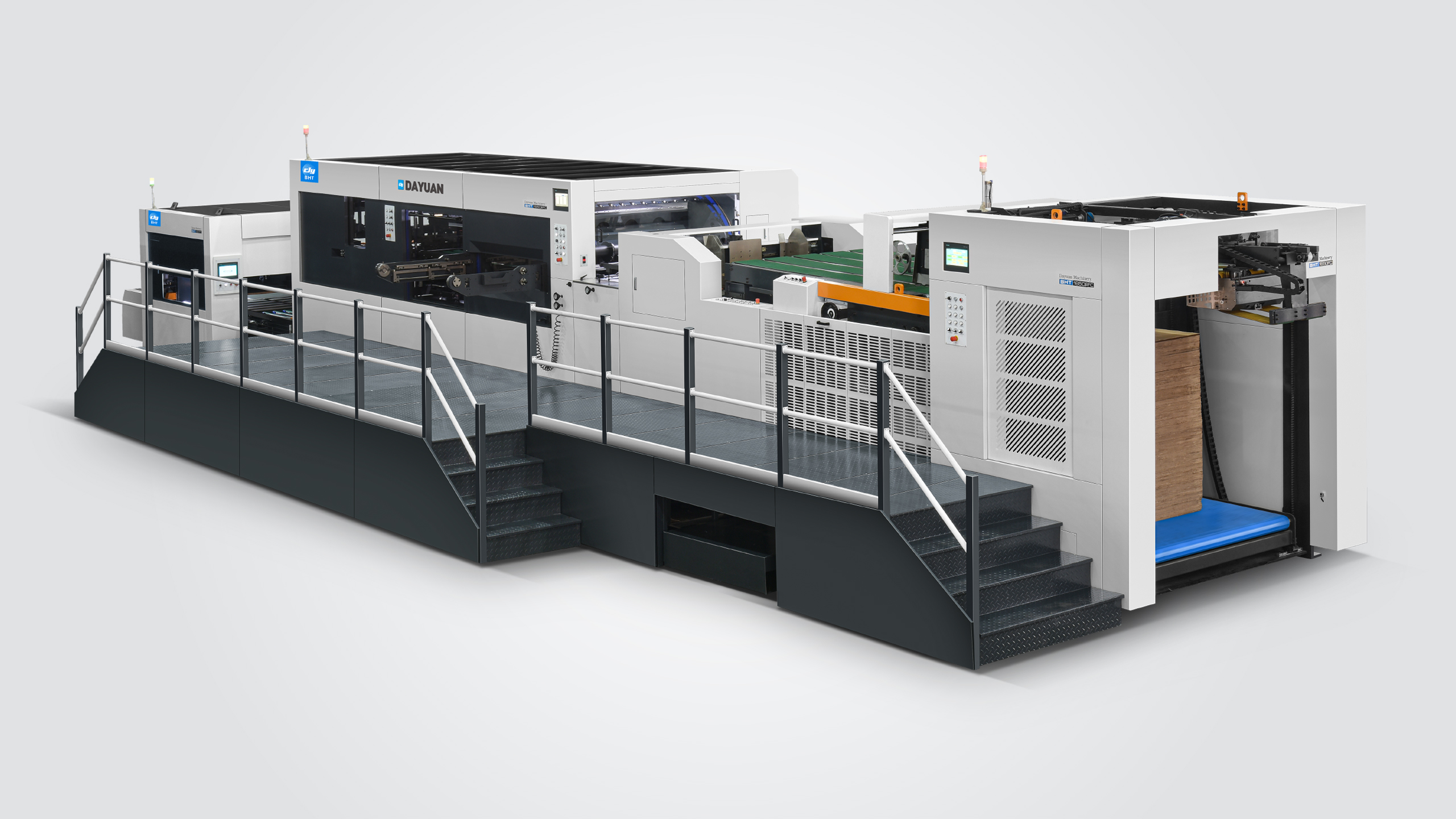

The BHT 1650EFC/1900EFC/2100EFC Automatic Die Cutting Machine Linkage Production Line with Down Feeder is a cutting-edge solution designed for high efficiency and precision in the packaging and printing industries. This advanced system integrates die cutting, creasing, and stripping functionalities with a down feeder, ensuring superior performance and productivity.

Key Features

Down Feeder System

The integrated down feeder system ensures accurate and consistent material feeding, reducing the risk of misfeeds and enhancing production efficiency. This feature is crucial for maintaining high-speed operations and ensuring reliable performance.

High Precision and Accuracy

The BHT 1650EFC/1900EFC/2100EFC series delivers millimeter-perfect die cutting, ideal for applications requiring detailed and exact specifications. This precision reduces material waste and ensures high-quality products.

Comprehensive Automation

These machines feature complete automation, including automatic feeding, die cutting, and stripping. This integrated approach streamlines the production process, minimizing manual labor and increasing efficiency.

Benefits

- Enhanced Efficiency: The combination of high-speed operations and integrated automation significantly boosts productivity, making it suitable for large-scale production.

- User-Friendly Interface: An intuitive touch-screen display provides easy setup and real-time monitoring, reducing the learning curve for operators and ensuring smooth operation.

- Safety Features: Equipped with emergency stop buttons and protective guards, the machines ensure a safe working environment, adhering to the highest industry standards.

Applications

The BHT 1650EFC/1900EFC/2100EFC series is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Their versatility and precision make them valuable assets for businesses looking to optimize their production processes and meet high-volume demands.

Conclusion

The BHT 1650EFC/1900EFC/2100EFC Automatic Die Cutting Machine Linkage Production Line with Down Feeder sets a new standard in the industry with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, these machines help businesses increase productivity while maintaining high quality and safety standards.

Partial Introduction

Auto pre-loader

Paper breaker

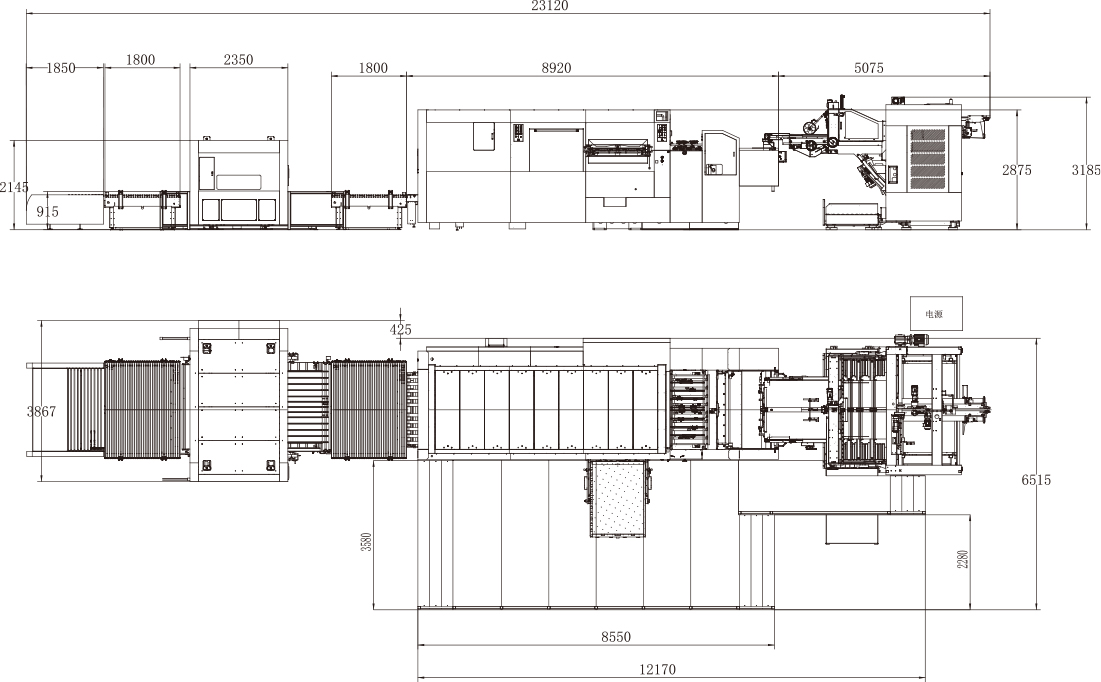

Drawing

Additional information

| Technical parameters of paper feeder | . |

|---|---|

| Paper Feeder Model | BHT-2100EFC |

| Paper Feeder Sheel Size | Max. 2100×1600mm Min. 650×450mm |

| Corrugated Board. Up To | 1-9mm |

| Batch Height | Max. 1800mm |

| Pile Weight | 1400kg |

| Paper Feeder Machine Weight | 5000kg |

| Technical parameters of die cutting machine | . |

| Cutting Machine Model | BHT-2100EFC |

| Max. Sheet Size | 2100×1600mm |

| Min. Sheet Size | 750×650mm |

| Max. Die Cutting Size | 2080×1580mm |

| Inner Chase Size | 2120×1630mm |

| Stock Range | ≤9mm corrugated paper, F, E, B, C, A and AB corrugated paper |

| Min. Gripper Waste | 10-18mm |

| Min. Gripper Margin | 6-12mm |

| Cutting Rule Height | 23.8mm |

| Max. Die Cutting Speed | 4000s/h |

| Max. Die Cutting Pressure | 450ton |

| Total Power Required | 47kw |

| Electrical Power | 380V, 50HZ, 3PH |

| Mobile Lower Platen Adjusting Range | ±1.5mm |

| Machine Dimension | 14370×6360×2970mm |

| Cutting Machine Weight | 51T |

| Sharding machine technical parameters | . |

| Sharding Machine Model | BHT-2100EFC |

| Sharding Machine Sheel Size | Max. 2100mm, Min. 650mm |

| Min. Batch Dimension In Machine Direction | 200mm |

| Max. Batch Thickness | 300mm |

| Min. Batch Thickness | 20mm |

| Batch Passage Height From The Floor | 900mm (adjustable) |

| Sharding Machine Weight | 5000kg |

| NOTE | Features that are the same in the table are written as one. |

Reviews

There are no reviews yet.