Product Description

| Upper knife roll has the British cutter method to reduce the load and noise when the cutter extend cutter life. To steel welding gave precision machining, and dynamic balance adjustment, effectively reduce the vibration and noise of the high-speed operation. Rotary cutting knife is made of special alloy steel precision machining, |

|

|

Dual position shaftless pivoting arm unwind stand

1)Max Reel Diameter: 1800mm |

| Slitting knife

Three sets of slitting knife unit to have a high speed, |

|

|

Motorized double decurler system

Effectively remove the curl of the roll to make the paper more flat, |

| Delivery and Auto Jogger System

Automatically goes down when paper piling up to a certain height. Conveyor system with mult-stage: |

|

|

Electronic control

INOVANCE Servo, INOVANCE PLC, Schneider, Eaton. |

| Delivery and Auto Jogger System

The stacker table has three sides shake finishing function, |

|

|

Transport department

The fast/slow speed belt is controlled by the stepless frequency converter, |

| Auto counting and Automatic marking

Type: Insert after counting precisely Auto -EPC (Edge Paper Control) Precision sensing nozzle which easily available and sensitive . Auto-tension control Put the paper roll diameter and paper weight number into touching screen, |

|

| Driving Motor system

1, AC Servo motor & encoder for cross knife |

|

Option Configuration

| 1. | Blade -Tungsten Steel |

| 2. | Cast Iron Main |

| 3. | Imports Of Electrical Appliances |

| 4. | Pneumatic slitting knife |

| 5. | Dust removal |

| 6. | Color code tracking system |

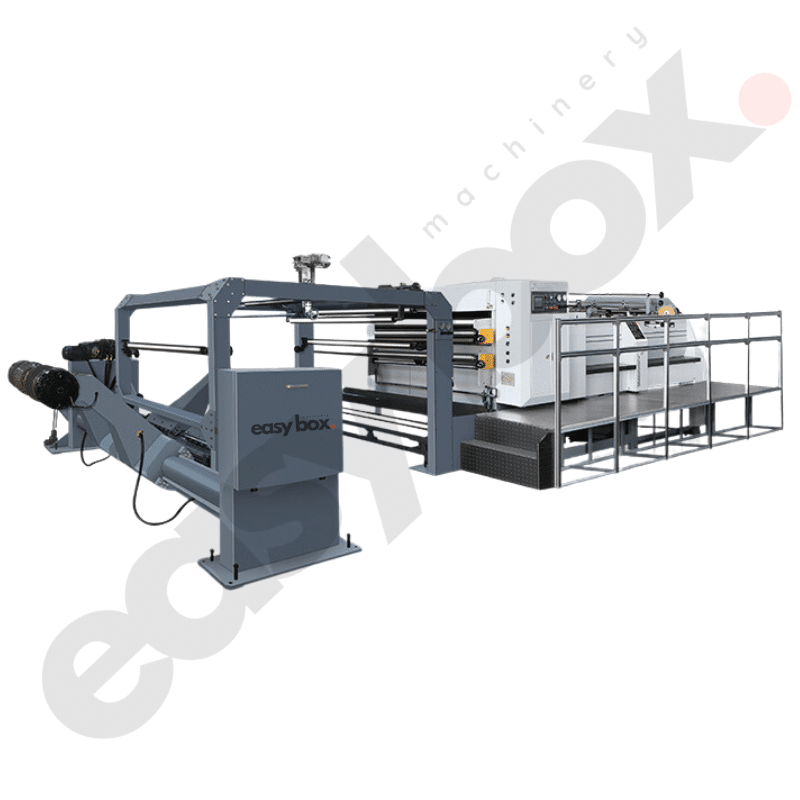

Sheeter Layout

2 reels unwinder (1 set EPC)

4 reels unwinder (3 sets EPC)

6 reels unwinder (5sets EPC)

Machine Parameters

| Modle of cutting paper | 上刀往复切割,下刀固定 |

|---|---|

| Reference weight of cutting pa | 50-550g |

| Max.roll diameter | 1800mm(71”)Max |

| 最大切纸宽度 | 1400mm/1700mm |

| Total power | 28kw |

| 切割长度范围 | 400-1450mm/400-1650mm |

| Cutting accuracy | +/-0.3mm |

| 对空气压缩机的要求 | Max.5.5kg/cm2x5m3/min) (23kw) |

| 重量 | 10.000kgs/13.000kgs |

评价

目前还没有评价