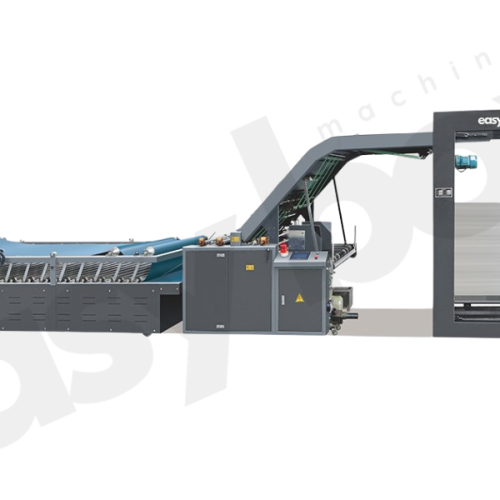

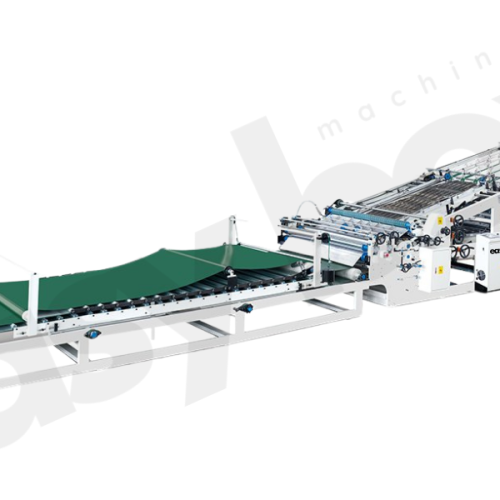

MHC 1100F/1300F/1500F/1650F/1900F Otomatik Kalıp Kesme ve Katlama Makinesi (Uç Kenar Besleyici)

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

Introduction to the MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine (Lead Edge Feeder)

The MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine with Lead Edge Feeder is a cutting-edge solution designed to meet the high demands of the packaging and printing industries. Combining precision, efficiency, and advanced technology, this machine ensures superior performance and reliability, making it an essential asset for high-volume production environments.

Temel Özellikler

Yüksek Hassasiyet ve Doğruluk

The MHC F series delivers millimeter-perfect die cutting and creasing, making it ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and ensures superior product quality, essential for maintaining high production standards.

Lead Edge Feeder System

The integrated lead edge feeder system ensures accurate and consistent material feeding, significantly reducing the risk of misfeeds. This system enhances the overall reliability and efficiency of the production process, maintaining high-speed operations and smooth, continuous production.

Yüksek Hızlı Performans

Designed for high-speed operations, the MHC F series significantly boosts productivity. Its robust construction and advanced technology enable it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy or quality.

Gelişmiş Otomasyon

The MHC F series features comprehensive automation, including automatic feeding, die cutting, and creasing functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

Kullanıcı Dostu Arayüz

Sezgisel dokunmatik ekran, kolay kurulum ve gerçek zamanlı izleme sağlar. Bu kullanıcı dostu arayüz, operatörler için öğrenme eğrisini en aza indirerek sorunsuz ve verimli bir çalışma sağlar.

Faydalar

- Gelişmiş Verimlilik: The combination of high-speed operations, lead edge feeder system, and advanced automation streamlines the workflow, reducing downtime and labor costs.

- Gelişmiş Güvenlik: Equipped with emergency stop buttons and protective guards, the MHC F series ensures a safe working environment, adhering to the highest industry standards.

- Çok yönlülük: Paketleme, etiketler, tabelalar ve özel baskı malzemeleri dahil olmak üzere çeşitli uygulamalar için idealdir. Hassasiyeti ve verimliliği, üretim süreçlerini optimize etmek ve yüksek hacimli talepleri karşılamak isteyen işletmeler için değerli bir varlık haline getirir.

Uygulamalar

The MHC 1100F/1300F/1500F/1650F/1900F is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

Endüstri Etkisi

By integrating the latest technology and automation, the MHC F series Automatic Die Cutting & Creasing Machine with Lead Edge Feeder sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Çözüm

The MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine with Lead Edge Feeder represents a significant advancement in die cutting and creasing technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the MHC F series means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

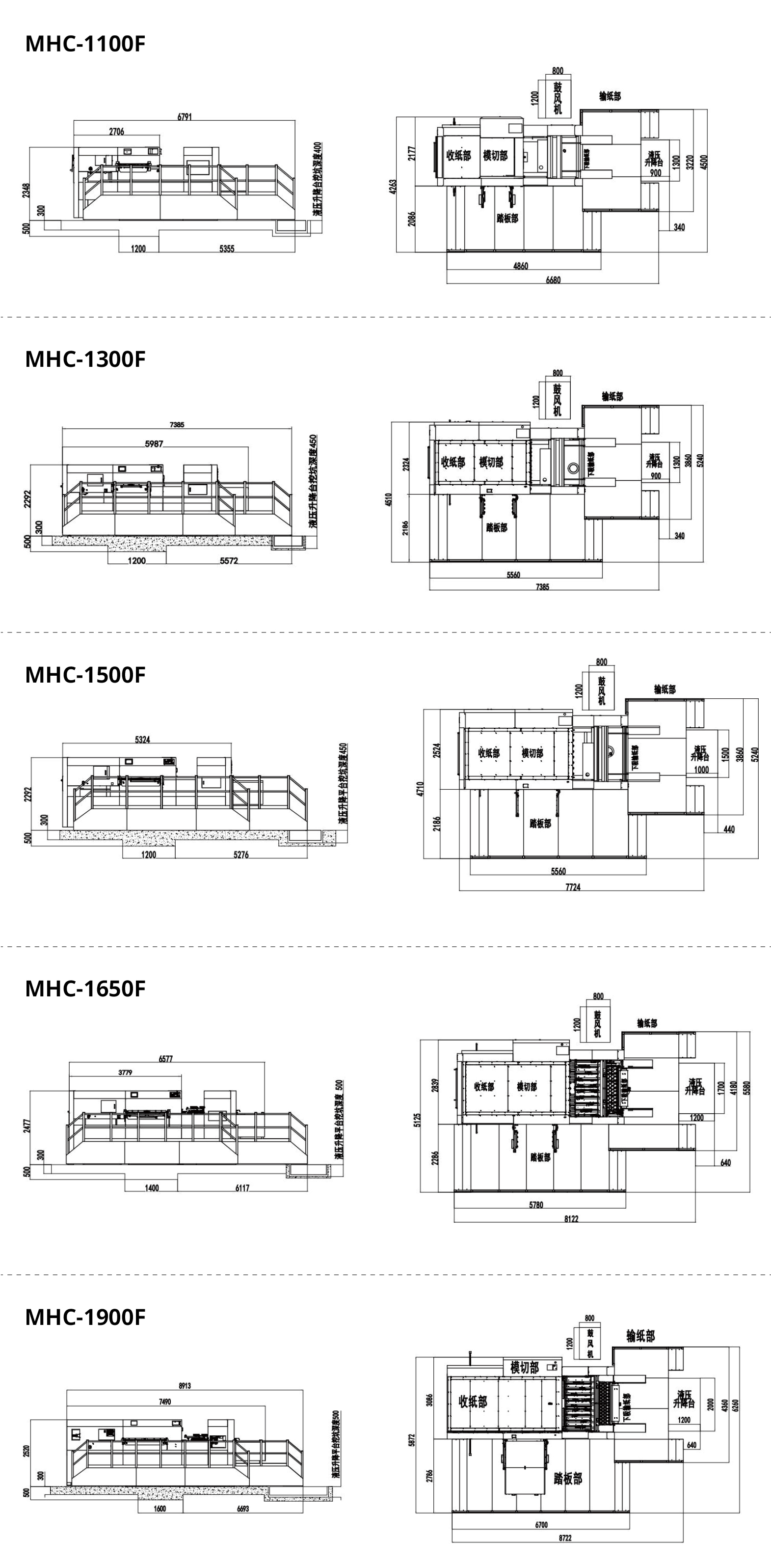

Çizim

Features Introduction

Ön kenar besleyici

Üst düzey dişli ve hassas Lead Edge Besleyici tasarımı, çeşitli kalitedeki oluklu mukavvaların tutarlı bir şekilde beslenmesine olanak tanır.

Yeni teknoloji poliüretan tekerlek yüzeyi, ızgara kaldırıcı ve hava yastıklı, düzgün besleme ve eğri levhalarda bile doğru hizalama sağlar.

Fine vacuum suction adjustment through inverter adapts to wide range stock from f flute to double wall corrugate.

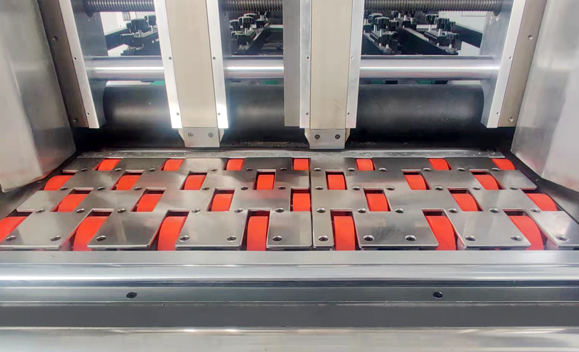

Sac iletim ve hizalama bölümü

Doğru hizalamayı garantilemek için seçilebilir sol ve sağ taraf itme yatırmaları.

Besleme zamanlamasının gelişmiş, kesintisiz ayarlanması, duruş süresini azaltır.

Ön gösterge, tutucu marjındaki değişikliklere uyum sağlamak için ileri geri kesintisiz ayarlanabilir.

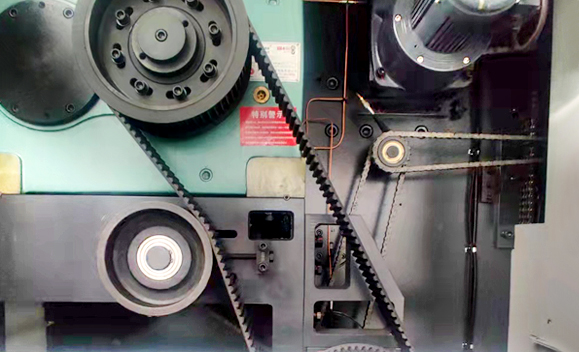

Timing belt driven device

Taiwan high precision intermittent segmentation ensure high positional precision for long time usage.

● MHC1300/1500 series adopt timing belt driven system

● MHC1650/1900 series adopt chain driven system

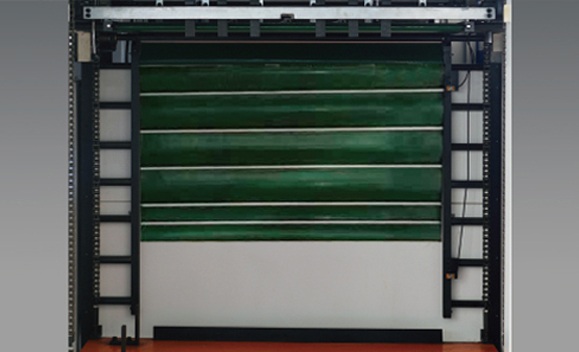

Paper collecting unit

Automatic delivery with non – stop curtain. This curtain moves into the delivery to catch the arriving sheets during the pile exchange.two blowers for paper collection can ensure neat collection of thin and thick papers.

Otomatik yağlama sistemi

Tahrik edilen parçaların daha iyi çalışmasını sağlamak için yoğunlaştırılmış otomatik yağlama sistemini benimseyin.

Ek bilgi

| Örnek | MHC-1100F |

|---|---|

| Maksimum Sayfa Boyutu | 1100×790mm |

| Min. Sayfa Boyutu | 470×450mm |

| Maksimum Kalıp Kesim Boyutu | 1070×770mm |

| Max. Working Speed | 7000s/h |

| Min. Gripper Waste | 12mm |

| Min. Gripper Margin | 6-12mm |

| Kesim Kuralı Yüksekliği | 23,8 mm |

| Electrical Power | 380V, 50HZ, 3PH |

| Air Pump Displacement | Air compressor displacement 1.05m3/min,12kg/cm2–( prepared by user) |

| Min. Motor Power | 11kw |

| Max. Working Pressure | 300T |

| Makine Ağırlığı | 16T |

| Makine Boyutu | 7000×4250×2350mm |

| Stok Aralığı | ≤7mm corrugated paper,E, B, C, A and AB corrugated paper |

| NOT | Tabloda aynı olan özellikler tek olarak yazılır. |

İncelemeler

Henüz yorum yapılmadı.