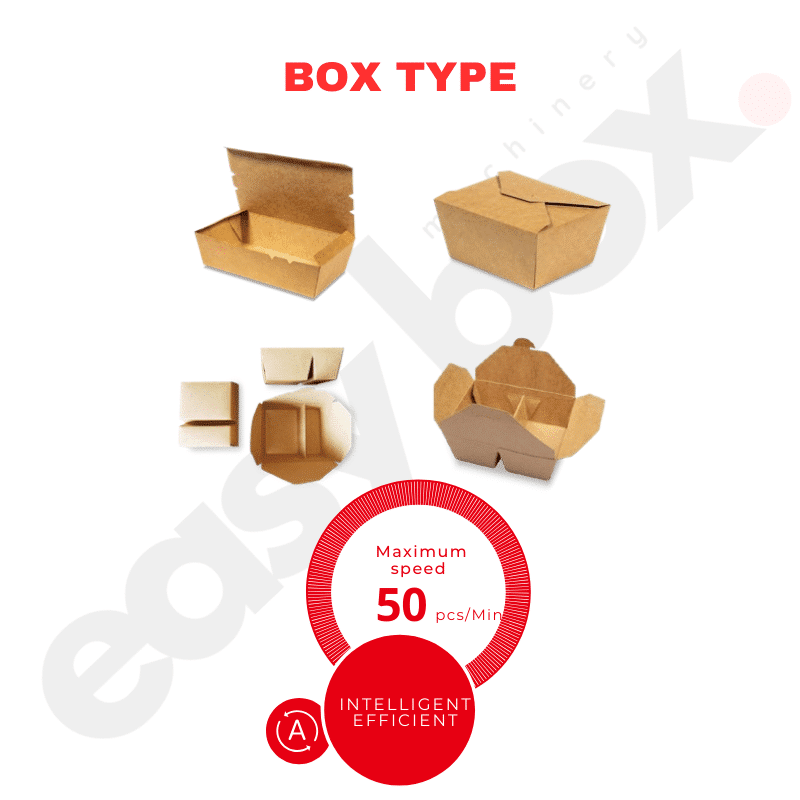

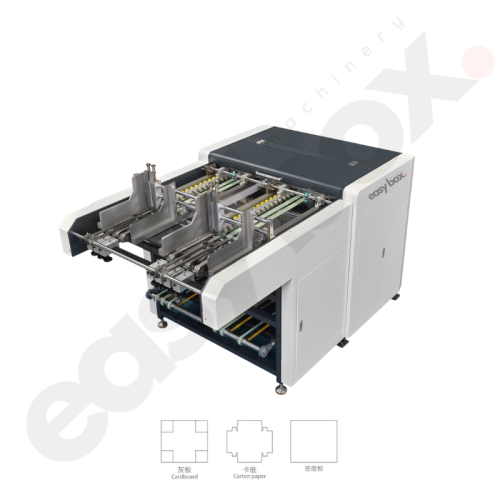

EBM-X550P Automatic-Carton Thermoforming Machine

(+86) 158 9968 3398 WhatsApp Chat

Product Description

Advancing Packaging Efficiency with the EBM-X550P Automatic Carton Thermoforming Machine

In the realm of packaging, the quest for more efficient, versatile, and sustainable solutions is endless. The Automatic Carton Thermoforming Machine represents a significant leap forward in this ongoing journey, offering a seamless blend of speed, precision, and environmental consciousness. This innovative machine is set to redefine the standards of carton packaging by automating the process of forming cartons from thermoplastic materials, which significantly enhances production efficiency and offers new possibilities in packaging design.

Innovative Thermoforming Technology

At the heart of the Automatic Carton Thermoforming Machine is its advanced thermoforming technology. This process involves heating a plastic sheet until it becomes pliable, then forming it into a specific shape using a mold, and finally trimming it to create a finished product. The automation of this process allows for high-speed production of cartons, which are increasingly favored for their durability, lightweight, and customizable properties. The precision of thermoforming ensures that each carton is consistently shaped and meets strict quality standards, making this machine an invaluable asset for businesses looking to elevate their packaging game.

Enhanced Production Efficiency

The automatic nature of the Carton Thermoforming Machine streamlines the production process, significantly reducing manual labor and minimizing the potential for human error. This not only speeds up production but also ensures that each carton is produced with uniform quality. The machine’s high-speed capabilities allow manufacturers to meet large orders quickly and efficiently, making it an ideal solution for industries with high production demands.

Versatility in Packaging Design

One of the standout features of the Automatic Carton Thermoforming Machine is its versatility. The machine can handle a variety of thermoplastic materials, including PET, PP, and PLA, offering businesses the flexibility to choose materials based on their specific needs and sustainability goals. Moreover, the thermoforming process allows for greater creativity in packaging design, enabling the production of custom-shaped cartons that stand out on the shelves and offer unique unboxing experiences for consumers.

Sustainability Benefits

In an era where environmental concerns are paramount, the Automatic Carton Thermoforming Machine offers significant sustainability advantages. The efficiency of the thermoforming process reduces waste material, and the ability to use recyclable and biodegradable plastics aligns with the growing demand for eco-friendly packaging solutions. By optimizing material usage and embracing sustainable materials, businesses can significantly reduce their environmental footprint while meeting consumer expectations for green packaging.

Conclusion

The Automatic Carton Thermoforming Machine is not just a technological advancement; it’s a transformative tool for the packaging industry, offering a way to achieve higher efficiency, more distinctive packaging designs, and greater sustainability. As businesses continue to seek innovative solutions to packaging challenges, this machine presents an opportunity to stay ahead of the curve, offering speed, precision, and eco-conscious packaging solutions that are tailored to the modern market’s needs. With the adoption of the Automatic Carton Thermoforming Machine, businesses are poised to redefine packaging efficiency and appeal, setting new standards for quality and sustainability in the process.

Machine Parameters

| Product Name | EBM-X550P Automatic-Carton Thermoforming Machine |

|---|---|

| Model | EBM-X550P |

| Suitable Material | 200-400g/m2 PE(PE Coated paper ) |

| Speed | 30-50pcs/min (Actual production according to product size) |

| Min. Paper Size | 120*100mm |

| Max. Paper Size | 480*480mm |

| Current | 380V |

| Total Power | One apartment 6.5KW, two apartments 7KW |

| Frequency | 50Hz |

| Air Source | Air Pressure 0.4-0.5Mpa(Need to buy compressor) |

| Weight | 700KG |

| Machine Dimension | 1550*1350*1800mm |