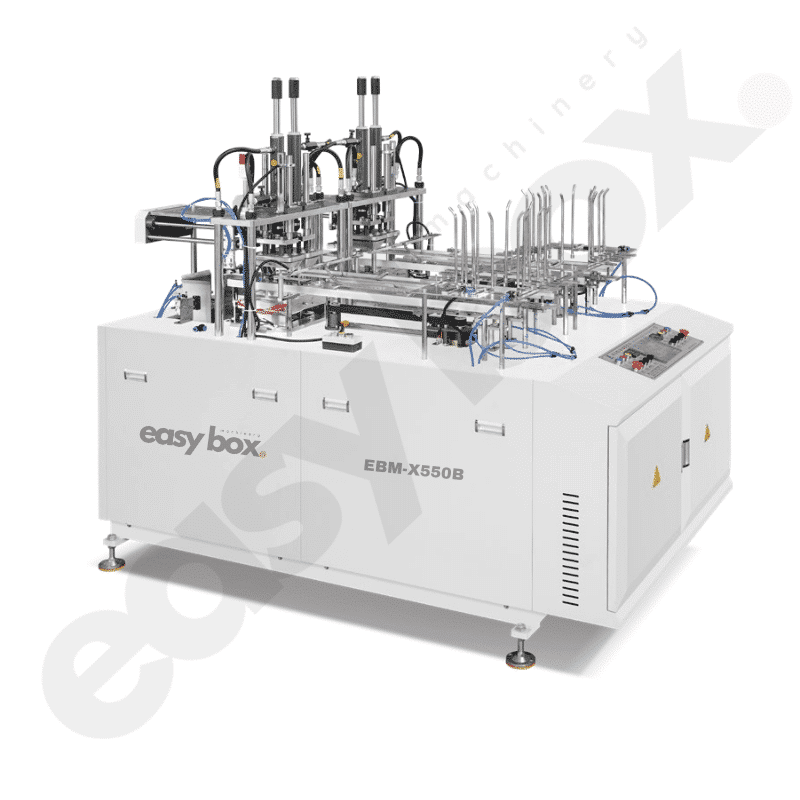

EBM-X550B Double Station Carton Thermoforming Machine

(+86) 158 9968 3398 WhatsApp Chat

Product Description

Revolutionizing Packaging with the EBM-X550B Double Station Carton Thermoforming Machine

The packaging industry stands at the brink of a transformative era, driven by the advent of innovative technologies like the Double Station Carton Thermoforming Machine. This groundbreaking equipment is setting new benchmarks for efficiency, quality, and sustainability in packaging production. By leveraging advanced thermoforming techniques across two stations simultaneously, this machine doubles the output, ensuring manufacturers can meet the increasing demand for high-quality, eco-friendly packaging solutions.

Dual-Station Efficiency

The core innovation of the Double Station Carton Thermoforming Machine lies in its ability to operate two independent thermoforming stations in parallel. This unique feature significantly enhances production capacity without compromising on the quality of the cartons produced. Each station operates autonomously, allowing for the continuous production of cartons, effectively halving production times compared to traditional single-station machines. This efficiency is crucial for manufacturers looking to scale up their operations to accommodate larger orders or to increase their market share in competitive packaging sectors.

Precision and Quality Control

Precision in packaging cannot be overstated, especially when it comes to thermoforming technology. The Double Station Carton Thermoforming Machine excels in this area, utilizing advanced sensors and control systems to ensure that each carton is formed to exact specifications. This meticulous attention to detail results in superior product quality, reducing waste and the need for reworks. The ability to maintain such high standards of precision at increased speeds is what sets this machine apart in the market.

Flexibility and Versatility

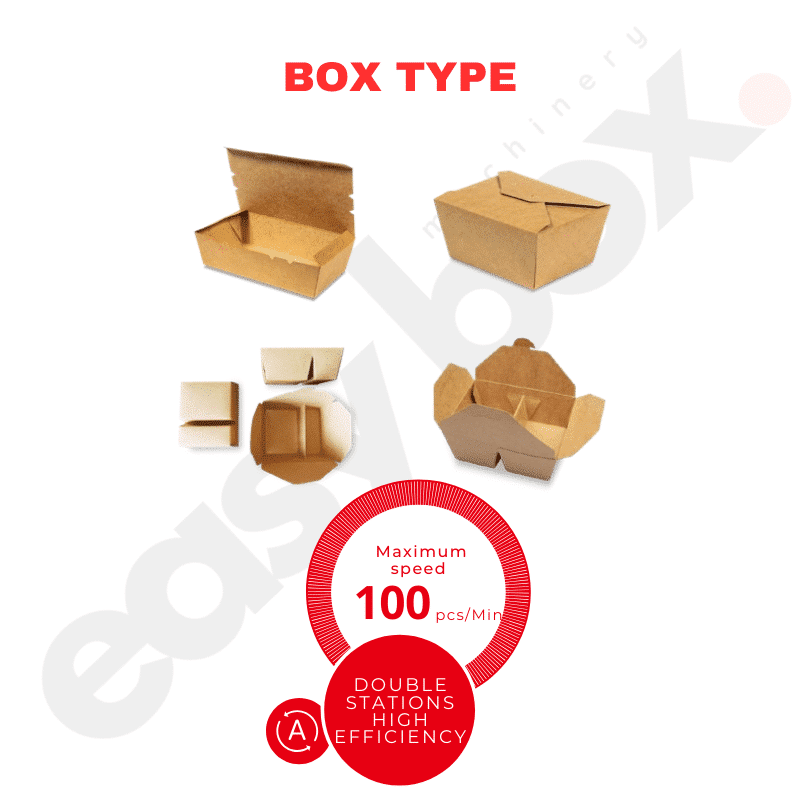

Adaptability is another hallmark of the Double Station Carton Thermoforming Machine. It is designed to work with a range of thermoplastic materials, including PET, PP, and biodegradable options, giving manufacturers the flexibility to respond to market demands and sustainability goals. Furthermore, the machine’s versatile design allows for the production of a wide variety of carton sizes and shapes, making it suitable for a broad spectrum of packaging applications—from food and beverage to electronics and beyond.

Sustainability at Its Core

In an industry increasingly focused on reducing environmental impact, the Double Station Carton Thermoforming Machine offers a path toward more sustainable packaging practices. The efficient use of materials and energy reduces waste and carbon footprint, while the compatibility with eco-friendly materials supports the production of recyclable and biodegradable packaging. This machine embodies the shift towards greener manufacturing processes, aligning with global sustainability trends and consumer preferences for environmentally responsible products.

Conclusion

The Double Station Carton Thermoforming Machine is not just an innovation; it’s a revolution in packaging production. It offers manufacturers the unprecedented ability to double their output while maintaining the highest standards of quality and precision. Its flexibility and sustainability features make it a future-proof investment for businesses aiming to thrive in the competitive landscape of packaging. As the industry continues to evolve, technologies like the Double Station Carton Thermoforming Machine will play a pivotal role in shaping the future of packaging, driving efficiency, quality, and environmental responsibility to new heights.

Machine Parameters

| Product Name | EBM-X550B Double Station Carton Thermoforming Machine |

|---|---|

| Model | EBM-X550B |

| Speed | 60-100 pcs/min (Actual production according to product size) |

| Min. Paper Size | 120*100mm |

| Max. Paper Size | 480*480mm |

| Current | 380V |

| Total Power | 8.5KW |

| Frequency | 50Hz |

| Air Source | Air Pressure 0.4-0.5Mpa(Need to buy compressor) |

| Weight | 1500KG |

| Machine Dimension | 2170*1450*2100mm |