EBM 900N Corrugation to Corrugation Laminating Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

EBM 900N Corrugation to Corrugation Laminating Machine: Enhancing Packaging Strength and Durability

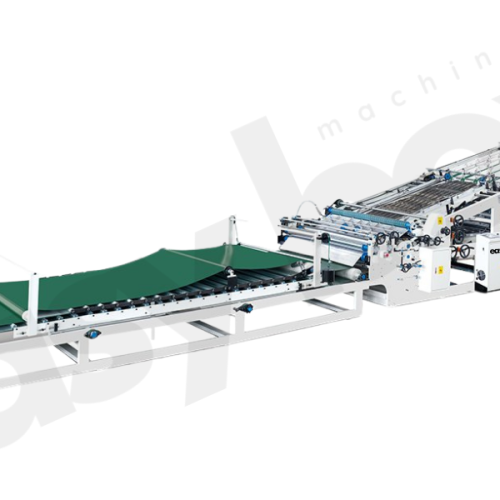

In the ever-evolving packaging industry, the Corrugation to Corrugation Laminating Machine emerges as a pivotal innovation, designed to significantly enhance the structural integrity and durability of corrugated cardboard. This specialized industrial equipment plays a crucial role in producing more robust and resilient packaging materials by laminating multiple layers of corrugated sheets together. Let’s delve into the functionality, benefits, and applications of this machine in modern packaging solutions.

What is a Corrugation to Corrugation Laminating Machine?

A Corrugation to Corrugation Laminating Machine is an advanced piece of machinery utilized in the packaging sector to bond two or more corrugated cardboard sheets together. The primary objective is to create a composite sheet that boasts increased thickness, strength, and carrying capacity. This process involves applying adhesive to one or more sheets, precisely aligning them, and then pressing them together to ensure a secure and uniform bond.

Key Features and Advantages

- Enhanced Strength and Durability: By laminating corrugated sheets together, the machine produces packaging that can withstand greater stresses and strains, making it ideal for transporting and protecting heavier items.

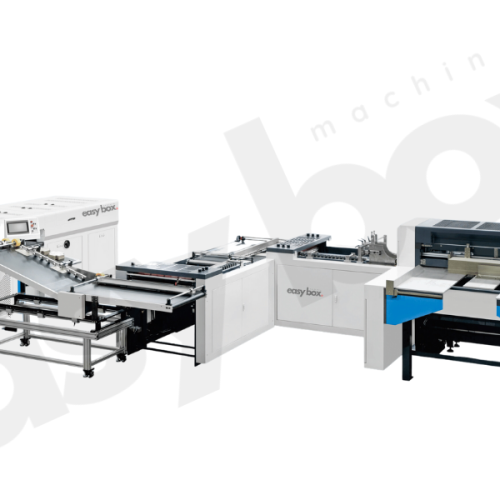

- Automatic Feeding Systems: These machines typically include automated feeding mechanisms that ensure consistent and efficient production, minimizing manual labor and optimizing throughput.

- Precision Bonding: With advanced alignment and pressing technologies, the machine guarantees that the adhesive is evenly distributed, ensuring a high-quality bond between the corrugated layers.

- Versatility: Capable of handling various sizes and types of corrugated cardboard, the machine offers flexibility in producing a wide range of packaging solutions tailored to specific needs.

Applications in the Packaging Industry

The Corrugation to Corrugation Laminating Machine finds its application in a multitude of packaging scenarios, particularly where enhanced durability and strength are paramount. From heavy-duty shipping boxes to protective packaging for delicate items, this machine enables manufacturers to create customized solutions that meet the rigorous demands of transportation and storage.

Conclusion

The introduction of the Corrugation to Corrugation Laminating Machine into the packaging industry marks a significant leap forward in the quest for more durable and reliable packaging solutions. Its ability to produce thicker, stronger corrugated cardboard opens up new possibilities for packaging design and functionality, providing manufacturers with the tools they need to innovate and excel. As the industry continues to grow and evolve, the role of such advanced machinery in meeting the diverse needs of consumers and businesses alike will undoubtedly expand, driving forward the future of packaging technology.

Additional information

| Product Information | EBM 900N Corrugation to Corrugation Laminating Machine INTRODUCTION Youbond corrugation to corrugation laminating machine, a customized model special for the corrugation manufacture, which fills a vacancy of the laminating equipment in the world. Its low investment, small occupy and easy set-up is a good complement to the large corrugation production line. This machine is easy handling, when set up the sheet size, all machine parts will adjust automatically, which completely realizes the intelligent operation. CHARACTERASTIC Max speed 10000sheet/hour |

|---|---|

| Top And Bottom Paper Feeding | Use imported Servo motor electric controlling system, with Japan NITTAsuction belt to make suction power inverter, and belt cleaned by water roller; Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation |

| Positioning Part | Servo control of the intermittent fixed position, in the process of positioning, positioning gau ge work as” start – speed up – tracking-speed reduction-stop ” curve speed run, make sure positioning more accurate. |

| Side Positioning | Left and right side synchronous block complete the accurate positioning, both top sheet and bottom paper are equipped with accurate positioning device on left and right. |

| Glue Roller | Stainless steel roller, never rust, after narrowly grinding, guaranteed,the minimum amount glue coated evenly. Down roller be cleaned by water roller. |

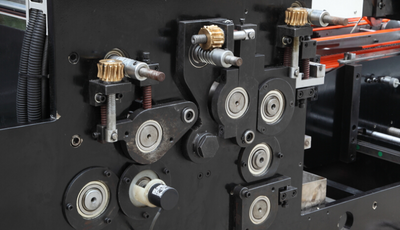

| Transmission | With imported double teeth belt drive and Switzerland rosta tension device ensure the drive accurate, stable and low noisy. |

| Electrical System | Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc on the screen at a glance. |

| Product Name | EBM 900N Corrugation to Corrugation Laminating Machine |

| Model | EBM 900N |

| Max Sheet Size | 1650X1450mm |

| Min Sheet Size | 550X550mm |

| Max Speed | 100M/Min |

| Accuracy | ±1.5mm |

| Machine Dimension | 10X2.4X2.3M |

| Machine Weight | 8000kg |

| Machine Power | 22KW/380V |

| Top Paper | A/B/C/E/F Two layers corrugated paper |

| Bottom Paper | A/B/C/E/F Two layers corrugated paper |

Reviews

There are no reviews yet.