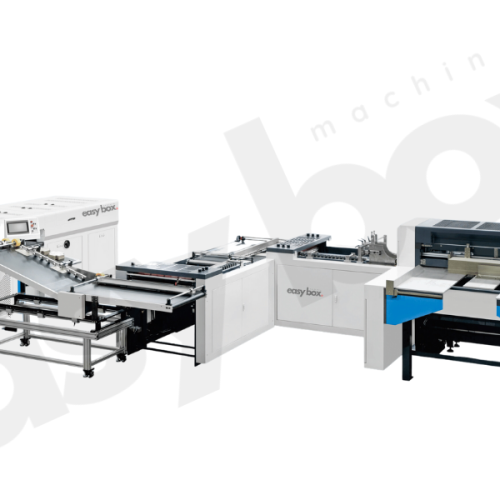

Machine à plastifier à grande vitesse EBM 1327E/1427E

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat WhatsApp

Product Description

The Ultimate Guide to EBM 1327E/1427E High Speed Laminating Machine

In today’s fast-paced production environments, efficiency and quality are paramount. Enter the high-speed laminating machine: a game-changer for industries ranging from printing and packaging to advertising. This comprehensive guide delves into the essence, benefits, and diverse applications of high-speed laminating machines, shining a light on how they are revolutionizing production processes.

What is a High-Speed Laminating Machine?

A high-speed laminating machine is a sophisticated piece of equipment designed to apply a protective film over various substrates, including paper, cardboard, and plastic. This process not only enhances the product’s durability and aesthetic appeal but also its resistance to environmental factors such as moisture and wear. With the capability to operate at significantly higher speeds than traditional laminating devices, these machines are indispensable in settings where time and quality are of the essence.

Key Benefits and Features

- Productivité améliorée : The hallmark of high-speed laminating machines is their ability to dramatically increase production rates. They can process large volumes of material in a fraction of the time it takes manual or slower automated systems, meeting tight deadlines and high demand with ease.

- Superior Quality: These machines ensure a consistent, bubble-free application of laminating film, resulting in a professional finish that enhances product longevity and visual appeal.

- Versatilité: Capable of handling a wide range of materials and film types, high-speed laminators offer the flexibility to cater to various product specifications and customer demands.

- Cost-Effectiveness: By streamlining the lamination process and reducing labor costs, these machines offer a compelling return on investment. Their efficiency can significantly lower per-unit costs, making high-quality laminated products more economically viable.

- Ease of Use and Automation: Advanced technology integration means that high-speed laminating machines often come with user-friendly interfaces and automation features. These reduce the need for extensive operator training and minimize human error, further enhancing productivity and consistency.

Applications Across Industries

High-speed laminating machines find applications across a broad spectrum of industries. In the printing and packaging sectors, they are essential for producing durable and attractive product packaging, labels, and shopping bags. The advertising industry relies on them for creating eye-catching posters and banners. Additionally, they are used in manufacturing safety signage, educational materials, and even automotive components, showcasing their versatility and importance in various production processes.

Choosing the Right Machine

When selecting a high-speed laminating machine, consider factors such as the types of materials you’ll be working with, the desired laminating speed, film thickness compatibility, and the machine’s overall footprint. It’s also important to assess the machine’s ease of operation, maintenance requirements, and the manufacturer’s support services.

Conclusion

The high-speed laminating machine is a cornerstone of modern production lines, offering unmatched efficiency, quality, and flexibility. Its benefits extend across industries, making it a critical investment for businesses looking to enhance their product offerings and streamline their operations. As technology advances, we can expect these machines to become even more integral to manufacturing and production, driving innovation and excellence in laminated products.

Machine Parameters

| Informations sur le produit | SERVO LAMINATING MACHINE |

|---|---|

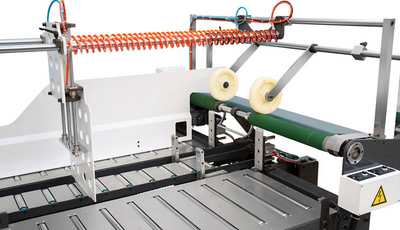

| Mécanisme d'alimentation de la feuille supérieure | équipé d'un chargeur automatique dédié à grande vitesse, la buse de levage et d'alimentation du papier peut ajuster librement l'angle du papier, pour garantir que le papier épais ou fin peut être livré rapidement et en douceur |

| Alimentation papier par le bas | Utilisez un système de contrôle électrique de servomoteur importé, avec une courroie d'aspiration japonaise NITTA pour créer un inverseur de puissance d'aspiration et une courroie nettoyée par un rouleau à eau ; Technologie brevetée pour garantir que le carton ondulé et le carton sortent en douceur et fonctionnent simplement |

| Système de positionnement | En utilisant des groupes de détection photoélectrique de position relative vers l'avant du papier inférieur, contrôlez le papier supérieur des deux côtés du servomoteur, action de compensation indépendante, le papier supérieur et le papier inférieur sont laminés avec précision |

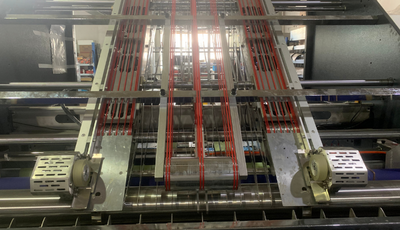

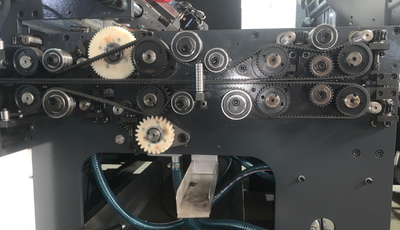

| Partie de transmission | Transmission par courroie synchrone à double denture importée, équipée d'un dispositif de tension pour assurer la précision de la transmission, stable, à faible bruit |

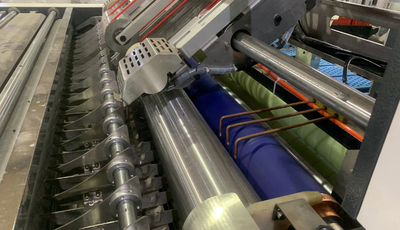

| Rouleau de colle | Rouleau en acier inoxydable, ne rouille pas, après un meulage serré, garantit une quantité minimale de colle uniformément appliquée. Le rouleau inférieur peut être nettoyé avec un rouleau à eau. |

| Système électrique | Conçu conformément aux exigences européennes CE, il garantit la stabilité de la machine, une efficacité élevée et un faible taux de défaillance. Grâce à l'interface homme-machine et à la combinaison PLC, affichez toutes les informations, telles que les avertissements, la détection d'erreur, les pannes et la vitesse de fonctionnement, etc. sur l'écran en un coup d'œil |

| Section de pré-empilage | Pré-empiler la pile de papier dans des conditions de non-stop, améliorer l'efficacité. La conception spéciale du cadre de pré-empilage de papier permet d'économiser du temps et des efforts. |

| Nom du produit | EBM 1327E High Speed Laminating Machine |

| Modèle | EBM 1327E / EBM 1427E |

| Taille maximale de la feuille | 1450×1450mm / 1650×1650mm |

| Taille minimale de la feuille | 400×400mm / 400×400mm |

| Épaisseur de la feuille supérieure | 120-500g / 120-500g |

| Precision For Front And Back | ±1mm / ±1mm |

| Consommation d'air | 0.2m3/min / 0.2m3/min |

| Overall | 15.5×2.4×2.4M / 15.7×2.6×2.4M |

| Puissance de la machine | 22KW / 25KW |

| Glue Application | White glue、Starch glue |

| Bottom Paper | A、B、C、E、F Corrugated paper |

Avis

Il n’y a pas encore d’avis.