Mi cuenta

Hola, inicia sesión$0.00

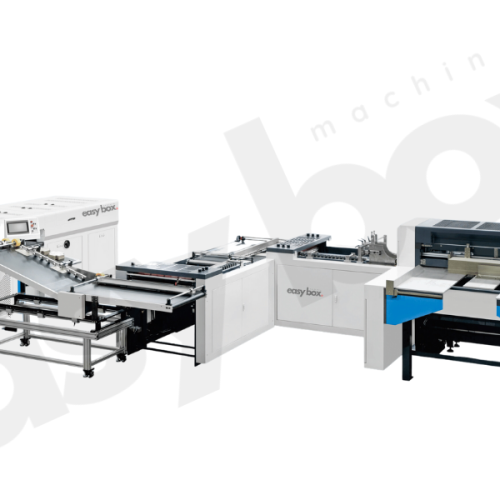

| nombre del producto | Máquina formadora de cajas de cartón de doble estación EBM-X1600P |

|---|---|

| Modelo | EBM-X1600P |

| Gramaje Papar | 200-620g |

| Velocidad | 50-550pcs/min |

| Grosor del papel | ≤1,6 mm |

| Mín. Tamaño de papel | 120*100mm |

| Máx. Tamaño de papel | 500*480mm |

| Actual | 380v/220v |

| Poder total | 5KW |

| Frecuencia | 50Hz |

| Peso | 2000KG |

| Dimensión de la máquina | 3600*1850*1700mm |

Máquina formadora de cajas de cartón de doble estación EBM-X1600P

(+86) 158 9968 3398 Chat de whatsapp

Precios bajos

Garantía de igualación de precios

Ajuste garantizado.

Siempre la pieza correcta

Expertos internos.

Conocemos nuestros productos

Devoluciones fáciles.

Rápido y sin complicaciones

Descripción

Elevating Packaging Efficiency: The EBM-X1600P Double-Station Carton Erecting Machine

In an era where the pace of manufacturing and packaging demands faster, more efficient solutions, the Double-Station Carton Erecting Machine stands out as a transformative technology. This advanced machine is specifically designed to meet the growing needs of industries for high-speed, reliable carton erecting, doubling the efficiency and productivity of packaging lines. Its dual-station design not only accelerates production rates but also ensures a consistent output of high-quality cartons, essential for businesses aiming to enhance their operational efficiency and meet consumer demands effectively.

Dual-Station Design: A Leap in Productivity

The Double-Station Carton Erecting Machine features a pioneering dual-station design, allowing for simultaneous operation on two different tasks. This means while one station is erecting a carton, the other can be folding, gluing, or performing quality checks, effectively doubling the workflow efficiency. This innovative approach to carton erecting significantly reduces turnaround times and increases output, making it an ideal solution for industries requiring high-volume packaging solutions.

Versatility and Precision

Versatility is another key advantage of the Double-Station Carton Erecting Machine. It is engineered to handle a wide range of carton sizes and styles, from simple boxes to complex shapes, accommodating the diverse needs of various industries, including food and beverage, electronics, and consumer goods. Moreover, the machine’s precision engineering ensures that each carton is erected with accuracy, maintaining consistent quality even at high speeds. This precision not only enhances the aesthetic appeal of the packaging but also improves its functionality, providing better protection for the products inside.

Reducing Waste, Promoting Sustainability

Sustainability is a critical concern in modern manufacturing, and the Double-Station Carton Erecting Machine addresses this by minimizing waste. Its precise operation reduces the occurrence of errors and the need for reworks, thereby lowering material wastage. Additionally, by optimizing the efficiency of the packaging process, it also reduces energy consumption, further contributing to an environmentally friendly production process.

Ease of Operation and Maintenance

Despite its advanced capabilities, the Double-Station Carton Erecting Machine is designed for ease of use. It features a user-friendly interface that simplifies the setup and operation process, allowing operators to easily adjust settings for different carton specifications. The machine’s design also facilitates easy access for maintenance, ensuring minimal downtime and keeping the production line running smoothly.

Future-Ready Solution

As businesses continue to seek ways to improve efficiency and sustainability in their operations, the Double-Station Carton Erecting Machine represents a future-ready solution. It embodies the integration of speed, versatility, and precision, setting a new benchmark for packaging technology. With its ability to significantly enhance production capabilities while maintaining high standards of quality and sustainability, the Double-Station Carton Erecting Machine is poised to become an indispensable tool in the packaging industry.

Conclusión

The Double-Station Carton Erecting Machine is a groundbreaking innovation in packaging technology, offering unparalleled efficiency, versatility, and sustainability. As industries worldwide strive to meet the ever-increasing demands for faster and more reliable packaging solutions, this machine provides a compelling answer, promising to revolutionize the way businesses approach their packaging operations. Its dual-station design not only maximizes productivity but also ensures that businesses can deliver high-quality packaging that meets the needs of today’s market, making it a key asset in the pursuit of operational excellence.

Información adicional

| nombre del producto | Máquina formadora de cajas de cartón de doble estación EBM-X1600P |

|---|---|

| Modelo | EBM-X1600P |

| Gramaje Papar | 200-620g |

| Velocidad | 50-550pcs/min |

| Grosor del papel | ≤1,6 mm |

| Mín. Tamaño de papel | 120*100mm |

| Máx. Tamaño de papel | 500*480mm |

| Actual | 380v/220v |

| Poder total | 5KW |

| Frecuencia | 50Hz |

| Peso | 2000KG |

| Dimensión de la máquina | 3600*1850*1700mm |

Productos relacionados

Únase a nuestro boletín para recibir actualizaciones instantáneas

Reciba nuestros correos electrónicos para obtener información sobre nuevos artículos, ventas y mucho más.

¡No te preocupes, no hacemos spam!

¿Necesitas ayuda?

Servicio al Cliente

Almacenar información

- La mejor empresa de máquinas de China

- www.easyboxmachinery.com

Copyright 2024 © Todos los derechos reservados. Desarrollado por easyboxmachinery.com