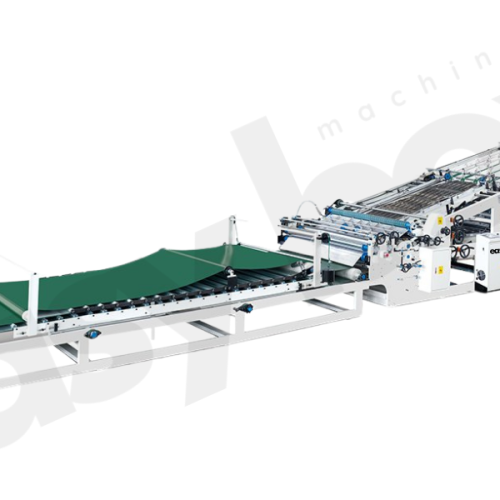

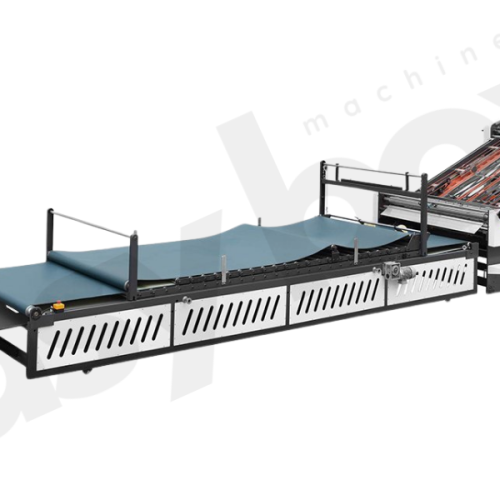

Máquina laminadora de alta velocidad EBM 1327E/1427E

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat de WhatsApp

Product Description

The Ultimate Guide to EBM 1327E/1427E High Speed Laminating Machine

In today’s fast-paced production environments, efficiency and quality are paramount. Enter the high-speed laminating machine: a game-changer for industries ranging from printing and packaging to advertising. This comprehensive guide delves into the essence, benefits, and diverse applications of high-speed laminating machines, shining a light on how they are revolutionizing production processes.

What is a High-Speed Laminating Machine?

A high-speed laminating machine is a sophisticated piece of equipment designed to apply a protective film over various substrates, including paper, cardboard, and plastic. This process not only enhances the product’s durability and aesthetic appeal but also its resistance to environmental factors such as moisture and wear. With the capability to operate at significantly higher speeds than traditional laminating devices, these machines are indispensable in settings where time and quality are of the essence.

Key Benefits and Features

- Productividad mejorada: The hallmark of high-speed laminating machines is their ability to dramatically increase production rates. They can process large volumes of material in a fraction of the time it takes manual or slower automated systems, meeting tight deadlines and high demand with ease.

- Superior Quality: These machines ensure a consistent, bubble-free application of laminating film, resulting in a professional finish that enhances product longevity and visual appeal.

- Versatilidad: Capable of handling a wide range of materials and film types, high-speed laminators offer the flexibility to cater to various product specifications and customer demands.

- Cost-Effectiveness: By streamlining the lamination process and reducing labor costs, these machines offer a compelling return on investment. Their efficiency can significantly lower per-unit costs, making high-quality laminated products more economically viable.

- Ease of Use and Automation: Advanced technology integration means that high-speed laminating machines often come with user-friendly interfaces and automation features. These reduce the need for extensive operator training and minimize human error, further enhancing productivity and consistency.

Applications Across Industries

High-speed laminating machines find applications across a broad spectrum of industries. In the printing and packaging sectors, they are essential for producing durable and attractive product packaging, labels, and shopping bags. The advertising industry relies on them for creating eye-catching posters and banners. Additionally, they are used in manufacturing safety signage, educational materials, and even automotive components, showcasing their versatility and importance in various production processes.

Choosing the Right Machine

When selecting a high-speed laminating machine, consider factors such as the types of materials you’ll be working with, the desired laminating speed, film thickness compatibility, and the machine’s overall footprint. It’s also important to assess the machine’s ease of operation, maintenance requirements, and the manufacturer’s support services.

Conclusión

The high-speed laminating machine is a cornerstone of modern production lines, offering unmatched efficiency, quality, and flexibility. Its benefits extend across industries, making it a critical investment for businesses looking to enhance their product offerings and streamline their operations. As technology advances, we can expect these machines to become even more integral to manufacturing and production, driving innovation and excellence in laminated products.

Machine Parameters

| Información del producto | SERVO LAMINATING MACHINE |

|---|---|

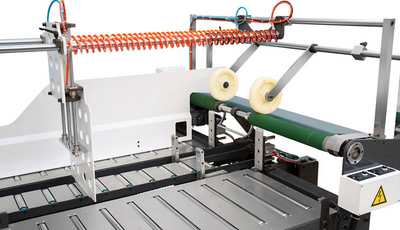

| Mecanismo de alimentación de hojas superiores | Equipado con un alimentador automático dedicado de alta velocidad, tanto la boquilla de elevación como la de alimentación del papel pueden ajustar libremente el ángulo del papel, para garantizar que se pueda entregar papel grueso o delgado de manera rápida y suave. |

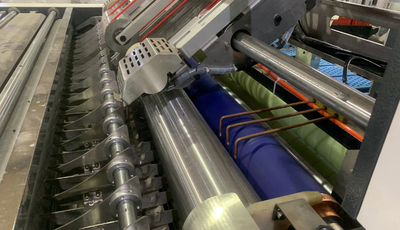

| Alimentación de papel por la parte inferior | Utilice un sistema de control eléctrico con servomotor importado, con correa de succión NITTA de Japón para hacer un inversor de potencia de succión y correa limpiada por un rodillo de agua; Tecnología patentada para garantizar que el corrugado y el cartón salgan sin problemas y con una operación simple |

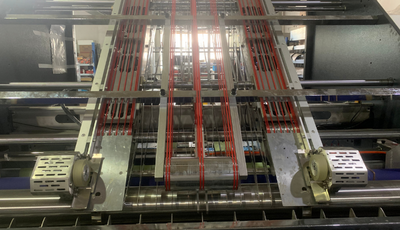

| Sistema de posicionamiento | Utilizando grupos de sensores fotoeléctricos que detectan la posición relativa hacia adelante del papel inferior, se controla el papel superior en ambos lados del servomotor, se realiza una acción de compensación independiente y se lamina con precisión el papel superior y el papel inferior. |

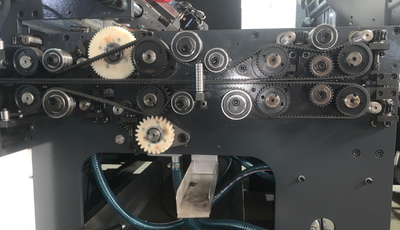

| Pieza de transmisión | Transmisión por correa síncrona de doble dentado importada, equipada con un dispositivo tensor para garantizar la precisión de la transmisión, estable y con bajo nivel de ruido. |

| Rodillo de pegamento | Rodillo de acero inoxidable, nunca se oxida, después de un pulido fino, se garantiza que la cantidad mínima de pegamento se cubra de manera uniforme. El rodillo inferior se limpia con un rodillo de agua. |

| Sistema eléctrico | Diseñado de acuerdo con los requisitos de la CE europea, garantiza la estabilidad de la máquina, alta eficiencia y pocas fallas. Mediante la interfaz hombre-máquina y la combinación de PLC, muestra toda la información, como advertencias, detección de errores, fallas y velocidad de operación, etc. en la pantalla de un vistazo. |

| Sección de preapilado | Preapilado de papel sin interrupción, lo que mejora la eficiencia. El diseño especial del marco de preapilado de papel ahorra tiempo y esfuerzo. |

| Nombre del producto | EBM 1327E High Speed Laminating Machine |

| Modelo | EBM 1327E / EBM 1427E |

| Tamaño máximo de hoja | 1450×1450mm / 1650×1650mm |

| Tamaño mínimo de hoja | 400×400mm / 400×400mm |

| Espesor de la hoja superior | 120-500g / 120-500g |

| Precision For Front And Back | ±1mm / ±1mm |

| Consumo de aire | 0.2m3/min / 0.2m3/min |

| Overall | 15.5×2.4×2.4M / 15.7×2.6×2.4M |

| Potencia de la máquina | 22KW / 25KW |

| Glue Application | White glue、Starch glue |

| Bottom Paper | A、B、C、E、F Corrugated paper |

Valoraciones

No hay valoraciones aún.