Mein Konto

Hallo, AnmeldenMelden Sie sich jetzt an und genießen Sie vergünstigte Einkäufe!

$0.00

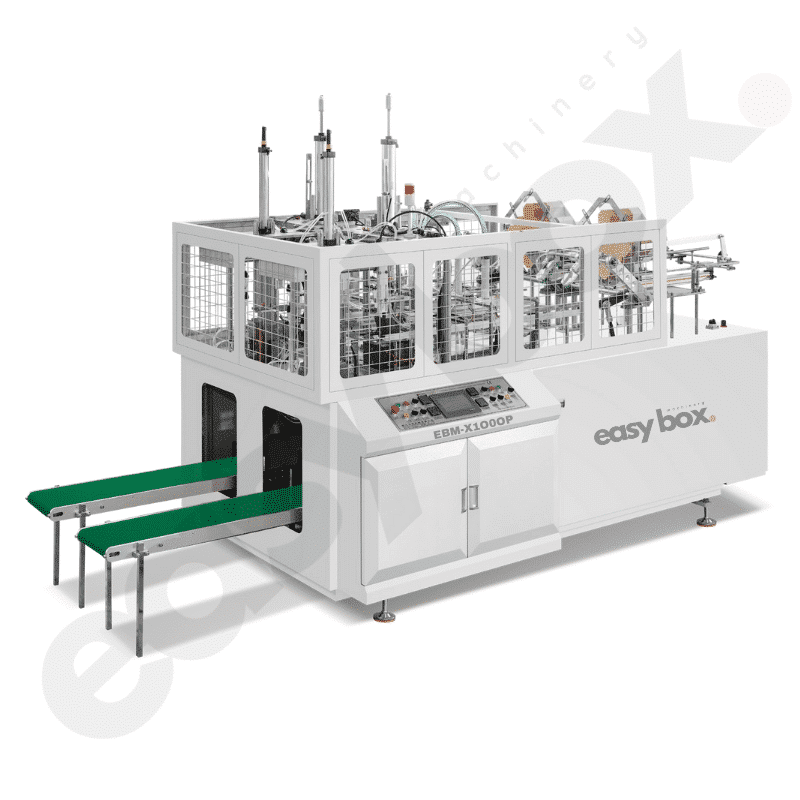

| Produktname | EBM-X1000P Doppelstations-Karton-Tiefziehmaschine (ZYLINDER) |

|---|---|

| Modell | EBM-X1000P |

| Geschwindigkeit | 60-100 Stück/min |

| Papiergrammatur | 200-500g |

| Min. Papiergröße | 120 x 100 mm |

| Max. Papiergröße | 480 x 480 mm |

| Aktuell | 380 V/220 V |

| Totale Kraft | 13KW |

| Frequenz | 50 Hz |

| Gewicht | 1700 kg |

| Maschinendimension | 3000 x 1650 x 2200 mm |

EBM-X1000P Doppelstations-Karton-Tiefziehmaschine (ZYLINDER)

(+86) 158 9968 3398 WhatsApp-Chat

Niedrige Preise

Preisgarantie

Garantierte Passform.

Immer das richtige Teil

Interne Experten.

Wir kennen unsere Produkte

Einfache Rückgabe.

Schnell und problemlos

Product Description

Verbesserung der Verpackungsinnovation: EBM-X1000P Die Doppelstationen-Tiefziehkartonmaschine mit Zylindertechnologie

Die Doppelstationen-Karton-Thermoformmaschine, ausgestattet mit fortschrittlicher Zylindertechnologie, stellt einen bedeutenden Fortschritt in der Verpackungsindustrie dar. Diese hochmoderne Maschine wurde entwickelt, um den wachsenden Anforderungen an Effizienz, Präzision und Nachhaltigkeit in der Verpackungsproduktion gerecht zu werden. Durch die Integration der Zylindertechnologie in eine Doppelstationen-Konfiguration optimiert diese Maschine nicht nur die Produktionsgeschwindigkeit, sondern gewährleistet auch beispiellose Genauigkeit und Qualität bei der Kartonbildung und setzt damit einen neuen Standard im Bereich der Thermoformung.

Innovative Zylindertechnologie für präzises Thermoformen

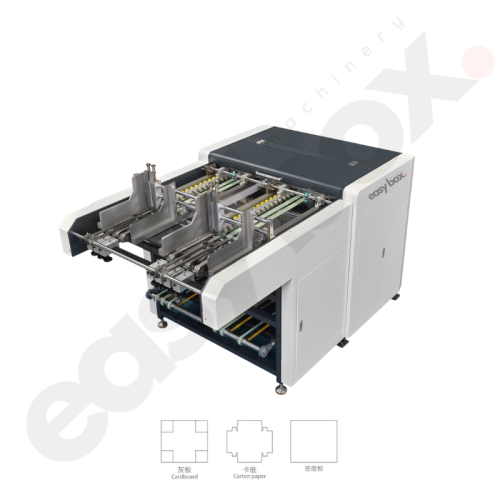

Die Integration der Zylindertechnologie in die Doppelstation-Karton-Thermoformmaschine ist ein bahnbrechender Fortschritt. Diese Technologie ermöglicht eine präzisere Kontrolle des Thermoformprozesses und ermöglicht die Herstellung von Kartons mit komplexen Details und gleichbleibender Qualität. Die Zylinder sorgen während der Formphase für einen stabilen und gleichmäßigen Druck, sodass Kartons exakte Spezifikationen mit minimaler Variabilität erfüllen. Dieses Maß an Präzision ist für Branchen von entscheidender Bedeutung, in denen die Integrität und das Aussehen der Verpackung von größter Bedeutung sind.

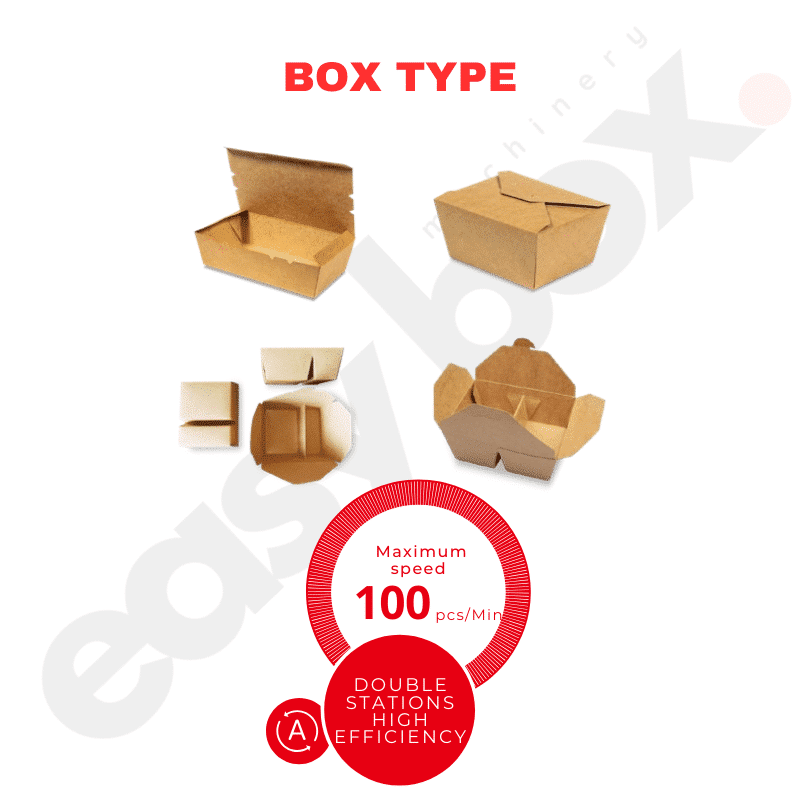

Duale Stationseffizienz für die Produktion großer Stückzahlen

Das Doppelstationen-Design dieser Maschine verdoppelt die Produktionskapazität, indem zwei Kartons gleichzeitig geformt werden können. Diese Konfiguration ist besonders vorteilhaft für Unternehmen mit hoher Nachfrage oder die ihre Produktionseffizienz steigern möchten. Der reibungslose Betrieb der Doppelstationen in Verbindung mit der Möglichkeit zum schnellen Formenwechsel sorgt dafür, dass Ausfallzeiten minimiert werden und die Produktionslinien schnell und effizient laufen.

Vielseitigkeit in allen Anwendungen

Die Vielseitigkeit der Doppelstationen-Karton-Thermoformmaschine mit Zylindertechnologie ist eine weitere ihrer Stärken. Sie kann eine breite Palette von Materialien verarbeiten, darunter PET, PP und umweltfreundliche Optionen wie PLA, und bietet Unternehmen die Flexibilität, Materialien basierend auf ihren Nachhaltigkeitszielen und spezifischen Verpackungsanforderungen auszuwählen. Darüber hinaus ist die Maschine aufgrund ihrer Fähigkeit, verschiedene Kartongrößen und -formen herzustellen, für ein breites Spektrum von Branchen geeignet, von Lebensmitteln und Getränken bis hin zu Pharmazeutika und Kosmetika.

Engagement für Nachhaltigkeit

Nachhaltigkeit steht bei modernen Verpackungslösungen im Vordergrund, und die Doppelstation-Karton-Thermoformmaschine mit Zylindertechnologie wurde unter diesem Gesichtspunkt entwickelt. Ihr effizienter Material- und Energieverbrauch reduziert den Abfall erheblich und verringert die Umweltbelastung durch die Verpackungsproduktion. Durch die Verwendung von recycelbaren und biologisch abbaubaren Materialien unterstützt diese Maschine die Herstellung nachhaltiger Verpackungen, die den wachsenden Umweltbedenken der Verbraucher gerecht werden.

Abschluss

Die Doppelstationen-Karton-Thermoformmaschine mit Zylindertechnologie definiert die Möglichkeiten der Verpackungsproduktion neu. Ihre Kombination aus Zylinderpräzision, Doppelstationen-Effizienz und Materialvielseitigkeit macht sie zu einem leistungsstarken Werkzeug für Unternehmen, die ihre Verpackungsprozesse erneuern möchten. Mit ihrem Fokus auf Nachhaltigkeit erfüllt diese Maschine nicht nur die aktuellen Anforderungen der Branche, sondern positioniert Unternehmen auch für zukünftigen Erfolg in einer Welt, die zunehmend auf umweltfreundliche Praktiken ausgerichtet ist. Während sich die Verpackungsbranche weiterentwickelt, sticht die Doppelstationen-Karton-Thermoformmaschine mit Zylindertechnologie als führende Lösung für eine qualitativ hochwertige, effiziente und nachhaltige Verpackungsproduktion hervor.

Machine Parameters

| Produktname | EBM-X1000P Doppelstations-Karton-Tiefziehmaschine (ZYLINDER) |

|---|---|

| Modell | EBM-X1000P |

| Geschwindigkeit | 60-100 Stück/min |

| Papiergrammatur | 200-500g |

| Min. Papiergröße | 120 x 100 mm |

| Max. Papiergröße | 480 x 480 mm |

| Aktuell | 380 V/220 V |

| Totale Kraft | 13KW |

| Frequenz | 50 Hz |

| Gewicht | 1700 kg |

| Maschinendimension | 3000 x 1650 x 2200 mm |

Ähnliche Produkte

Abonnieren Sie unseren Newsletter für sofortige Updates

Erhalten Sie unsere E-Mails für Informationen zu neuen Artikeln, Sonderangeboten und vielem mehr.

Keine Sorge, wir spammen nicht!

Easy Box Machinery

Stärken Sie Ihr Unternehmen, gestalten Sie die Zukunft!

Brauchen Sie Hilfe?

Montag – Freitag: 9:00–20:00 Uhr

Samstag: 11:00 – 15:00 Uhr

Kundendienst

Information speichern

- Das beste chinesische Maschinenunternehmen

- www.easyboxmachinery.com

Copyright 2024 © Alle Rechte vorbehalten. Unterstützt von easyboxmachinery.com