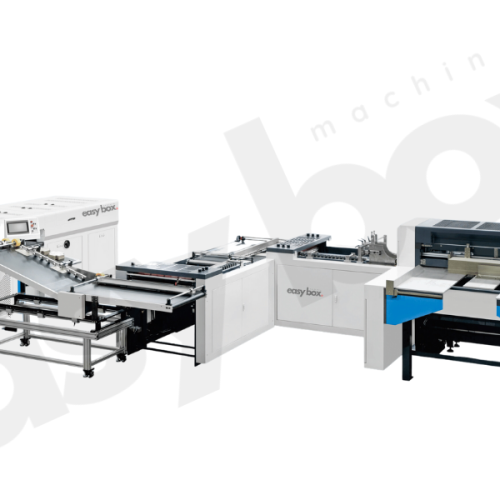

EBM S-850 Papierklebemaschine mit manueller Zuführung

(+86) 158 9968 3398 WhatsApp-Chat

Product Description

Bemerkungen: Das Förderband kann auf 4,5 Meter, 5 Meter, 6 Meter, 8 Meter und 10 Meter Länge angepasst werden (jede Größe kann angepasst werden).

EBM S-850 Papierklebemaschine mit manueller Zuführung

In der vielfältigen Landschaft der Fertigung und Produktion, in der Automatisierung das Maß aller Dinge ist, erweist sich die Papierklebemaschine mit manueller Zuführung als Beweis für den bleibenden Wert menschlicher Handarbeit und Vielseitigkeit bei Spezialvorgängen. Dieses Gerät ist ein Eckpfeiler für Branchen, in denen Präzision, Handwerkskunst und die Fähigkeit, sich schnell an einzigartige Projektanforderungen anzupassen, im Vordergrund stehen. Von Boutique-Druckereien bis hin zu kundenspezifischen Verpackungslinien bietet die Papierklebemaschine mit manueller Zuführung eine Mischung aus Kontrolle und Flexibilität, die von vollautomatischen Systemen nicht erreicht wird. Dieser Artikel befasst sich mit den Eigenschaften, Vorteilen und vielfältigen Anwendungen von Papierklebemaschinen mit manueller Zuführung und hebt ihre entscheidende Rolle in maßgeschneiderten und kleinmaßstäblichen Produktionsumgebungen hervor.

Die Papierklebemaschine mit manueller Zuführung: Ein genauerer Blick

Im Kern ist die Papierklebemaschine mit manueller Zuführung ein Gerät, das zum Auftragen von Klebstoffen auf Papierprodukte entwickelt wurde und bei dem ein Bediener die Materialien manuell einführen muss. Dieser manuelle Eingriff ermöglicht eine beispiellose Flexibilität, sodass Bediener die Maschine unterwegs auf eine Vielzahl von Papiergrößen, -stärken und -typen einstellen können. Mit Funktionen, die für bestimmte Projekte angepasst werden können, darunter anpassbare Klebemuster und -mengen, eignen sich diese Maschinen besonders für Vorgänge, bei denen jedes Stück unterschiedliche Anforderungen haben kann.

Vorteile der manuellen Bedienung

- Verbesserte Flexibilität und Anpassung: Die Möglichkeit, Papier manuell in die Klebemaschine einzuführen, ermöglicht sofortige Anpassungen und ermöglicht die Berücksichtigung individueller und kleiner Projekte mit unterschiedlichen Spezifikationen.

- Kosteneffizienz für Nischenmärkte: Diese Maschinen sind ideal für Unternehmen, die keine großen Stückzahlen produzieren müssen. Sie stellen eine kosteneffiziente Investition dar und minimieren den Bedarf an großen Kapitalausgaben für vollautomatische Maschinen.

- Benutzerfreundlichkeit und Wartung: Die einfachere mechanische Konstruktion manueller Maschinen ermöglicht eine unkomplizierte Bedienung und Wartung, wodurch der Bedarf an Spezialschulungen und kostspielige Ausfallzeiten reduziert werden.

- Qualitätskontrolle: Durch die direkte Einbindung in den Klebevorgang ist gewährleistet, dass die Bediener in Echtzeit Anpassungen vornehmen können, um optimale Qualität zu erzielen, und so einen praktischen Ansatz zur Qualitätssicherung erhalten.

Wo Papierklebemaschinen mit manueller Zuführung glänzen

Die einzigartigen Eigenschaften von Papierklebemaschinen mit manueller Zuführung machen sie für mehrere wichtige Anwendungen unverzichtbar:

- Maßgeschneiderte Verpackungserstellung: Maßgeschneiderte Verpackungen für kleine Unternehmen, handwerkliche Produkte oder kleine Auflagen, bei denen Individualisierung und Präsentation im Vordergrund stehen.

- Buchbinderei im Handwerk: Anfertigen hochwertiger, personalisierter Bücher oder Alben, bei denen jedes Stück individuelle Liebe zum Detail und Präzision erfordert.

- Benutzerdefinierte Druckvorgänge: Unterstützung von Druckereien, die auf personalisiertes Briefpapier, Einladungen und andere Drucksachen spezialisiert sind, für die spezielle Klebeanwendungen erforderlich sind.

Abschluss

Während der Trend zur Automatisierung weiterhin die Zukunft der Fertigung prägt, ist die manuelle Papierklebemaschine ein Vorbild für Branchen, die Wert auf Handwerkskunst, individuelle Anpassung und den menschlichen Faktor legen. Diese Maschinen ermöglichen es den Bedienern, sich schnell an projektspezifische Anforderungen anzupassen und sicherzustellen, dass selbst in einer kleinen, maßgeschneiderten Produktionsumgebung Effizienz und Qualität Hand in Hand gehen können. Für Unternehmen, die Nischenmärkte bedienen oder hochgradig individuelle Produkte anbieten möchten, ist die manuelle Papierklebemaschine nicht nur ein Werkzeug, sondern ein wichtiges Kapital, das die Lücke zwischen traditioneller Handwerkskunst und modernen Produktionstechniken schließt.

Machine Parameters

| Produktname | EBM S-850 Papierklebemaschine mit manueller Zuführung |

|---|---|

| Modell | EBM S-850 |

| Geschwindigkeit | 8-40 Stück/min |

| Papierdicke | 80-250g |

| Papierbreite | 60-800 mm |

| Stromspannung | 220/380 V |

| Leistung | 8kw |

| Maschinengewicht | 900 kg |

| Maschinendimension | 7300 x 1700 x 1100 mm |