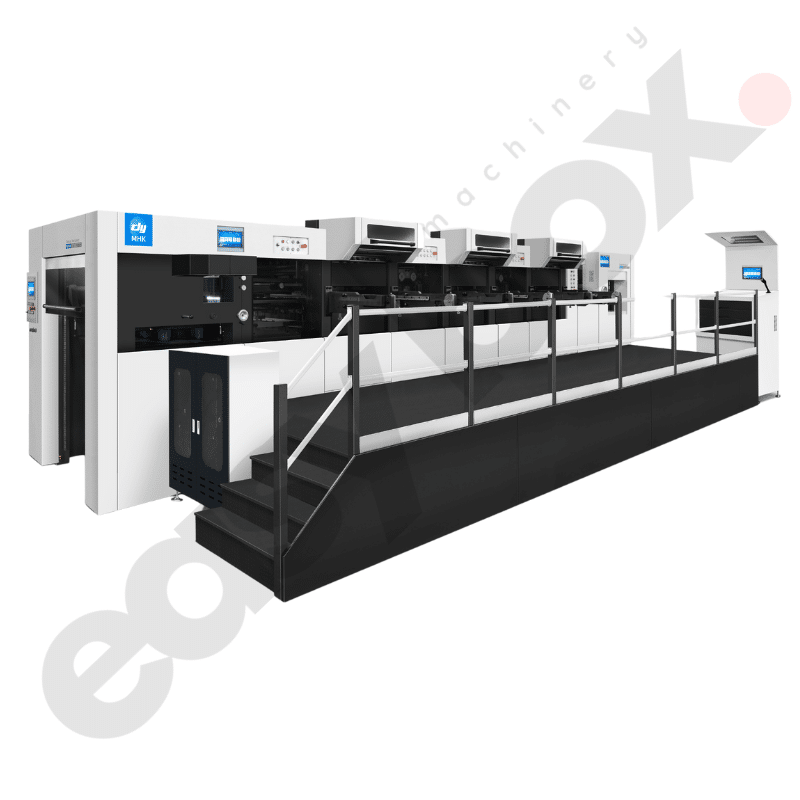

MHK 3S1050TTTC TRIOPRESS 自动高速三重烫金模切机(带清废功能)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp 聊天

Product Description

绘画

MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping: Superior Precision and Efficiency

The MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping is an advanced solution designed to meet the rigorous demands of modern post-press operations. By integrating multiple processes into a single seamless operation, this machine offers exceptional precision, efficiency, and reliability.

主要特点和优点

一次性完成多工艺

The MHK 3S1050TTTC TRIOPRESS can perform multiple processes in one pass, significantly enhancing production efficiency and reducing labor costs. The machine’s capabilities include:

- Hot Stamping + Hot Stamping + Hot Stamping: Achieve intricate and high-quality triple foil designs in a single pass.

- 烫印+烫压+深压花: Combine double foil stamping with deep embossing for enhanced texture and detail.

- Hot Stamping + Hot Stamping + Die Cutting: Integrate double foil stamping with precise die cutting for a streamlined process.

- Hot Stamping + Deep Embossing + Die Cutting: Enhance products with foil stamping, deep embossing, and die cutting in one operation.

- Deep Embossing + Deep Embossing + Deep Embossing: Achieve multiple deep embossing effects for superior texture and detail.

- 烫印+烫压+模切+清废: Perform double foil stamping, die cutting, and efficient stripping in a single seamless operation.

- 烫印+深压花+模切+清废: Combine foil stamping, deep embossing, die cutting, and stripping for high-quality finishes.

- 深压花+深压花+模切+清废: Integrate multiple deep embossing processes with die cutting and stripping for superior results.

精准高效

The MHK 3S1050TTTC TRIOPRESS excels with its ability to accurately register multiple processes in one pass, a capability that traditional machines and duopress machines often cannot match. This precision ensures high-quality results and maximizes production efficiency.

坚固的结构和设计

Constructed from high-quality materials, the MHK 3S1050TTTC is built for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

用户友好界面

该机器具有直观的用户界面,操作员可以轻松设置和调整参数、监控生产过程并解决问题。这种用户友好的设计提高了生产率并缩短了新操作员的学习时间。

高效剥离系统

高效的剥离系统自动去除废料,简化生产流程并减少人工干预。此功能可提高效率,确保更清洁的生产环境,并提高成品的整体质量。

安全功能

Safety is a top priority with the MHK 3S1050TTTC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

多种应用

The MHK 3S1050TTTC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- 印刷: 为印刷材料提供高质量的压印、压花和切割。

- 包装: 为包装材料提供精密的模切、烫金和剥离。

- 标签和标记: 为标签和标记创建详细且有吸引力的设计。

- 装饰应用: 通过复杂的切割、箔装饰和浮雕来增强装饰物品。

提高生产力

The integration of high-speed operation, triple hot stamping, deep embossing, die cutting, and stripping functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

技术进步

The MHK 3S1050TTTC TRIOPRESS incorporates advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

结论

The MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their post-press processes. Whether for printing, packaging, or decorative applications, the MHK 3S1050TTTC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

部分介绍

送料单元

四个拾取头和四个前吸头具有角度调节功能,可处理不同种类的材料。

喂料台

生产过程中手动调整片材定位至前规的同步装置,片材压紧装置(将片材引导至前规)。

烫印部分

加热底座设有 20 个加热区,每个加热区的温度可单独调节,实现高效、准确的温度控制。

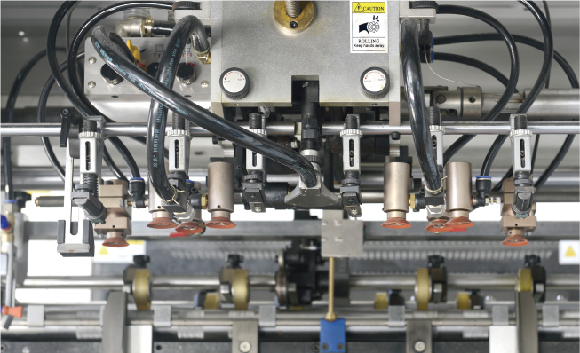

箔推进装置

三组纵向箔推进轴和两组横向箔推进轴由可单独编程的伺服电机驱动,用于短箔和长箔步进。

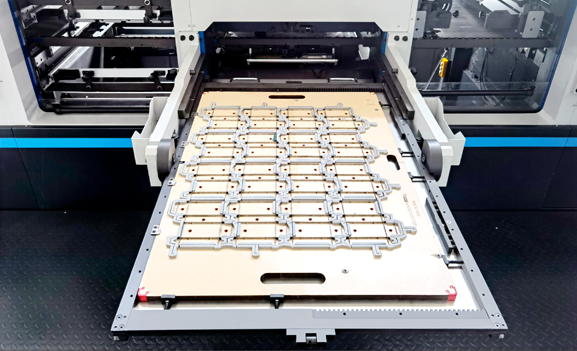

模具快速锁紧装置

采用中心线系统和快速锁定装置,节省准备时间。

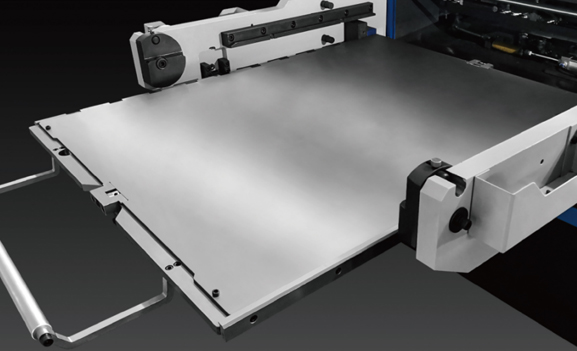

板材设置

15mm 精密地面支撑底板上设有 5mm 硬化冲压板或 3.5mm + 1.5mm 夹层冲压板,在运行和横向均可进行 +/-0.9mm 微调,以便快速设置和轻松准备。

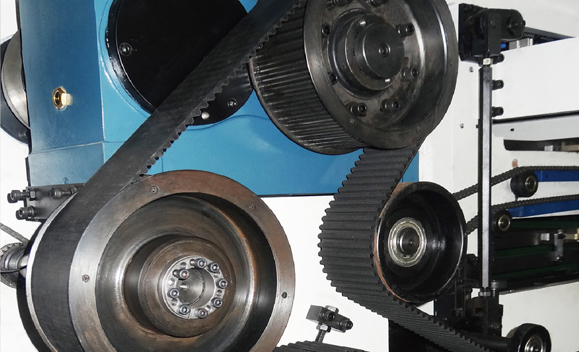

扭矩限制器

台湾高精度间歇分割器,确保长时间使用时的高定位精度。

台湾力矩限制器以其灵敏的限位保护性能,能准确地防止人为操作事故,保障人身及机器的安全。

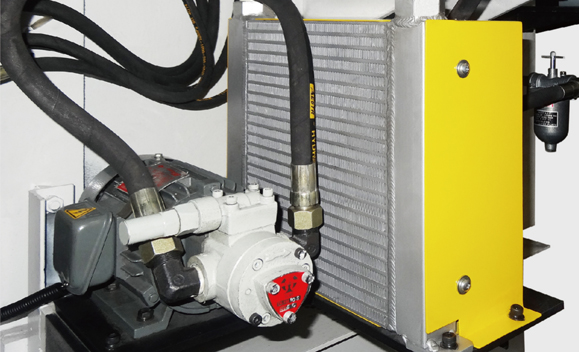

主电机润滑系统

台湾产全自动油泵冷却循环系统,保证主电机长时间高速润滑。

配有油压表,并设有油压报警装置。

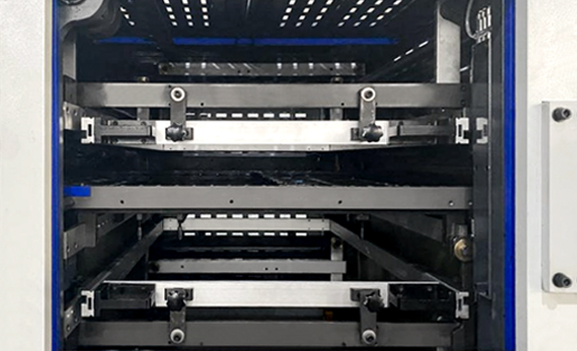

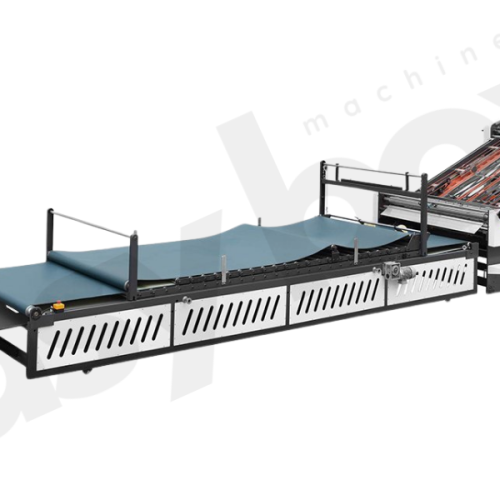

剥离装置

采用中心线系统,上、下剥线工具安装架可拉出,以便作业设置和准备。

夹持器边缘废料清除装置

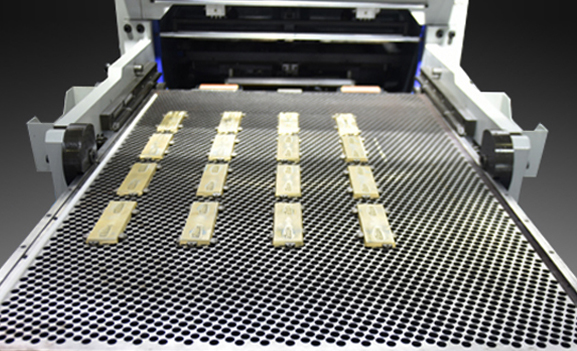

夹持器边缘剥离和去除系统配有传送带,用于将夹持器边缘废料侧向去除到驱动侧。

发货单位

自动收纸,带不停机挡板。挡板在纸堆交换过程中移动至收纸口以接住到达的纸张。两个收纸风机可确保薄纸和厚纸整齐收集。

德国真空泵

德国贝克无油风机、真空泵。

自动润滑系统

采用集中自动润滑系统,确保各传动部件良好运转。

Machine Parameters

| 模型 | MHK-3S1050TTTC |

|---|---|

| 功能 | 1. hot stamping+hot stamping+hot stamping |

| Max.sheet size | 1050×750毫米 |

| Min.sheet size | 400×360毫米 |

| Max.die cutting size | 1040×720毫米 |

| Max.hot stamping size | 1040×720毫米 |

| Gripper margin | 9~17毫米 |

| 内槽尺寸 | 1080×745mm |

| 库存范围 | 80~2000g/m2 Cardboard, 0.1~2mm Cardboard, ≤4mm Corrugated |

| Die cutting accuracy | ≤±0.075毫米 |

| Common stamping accuracy | ≤±0.075毫米 |

| Hologram positioning stamping accuracy | ≤±0.075毫米 |

| Max.die cutting force | 600吨+600吨+600吨 |

| Max.working speed | 6200秒/小时 |

| Max.feeder pile height (wooden pallet included) | 1600毫米 |

| Max.delivery pile height (wooden pallet included) | 1400毫米 |

| Max.gold foil diameter | 纵向φ250mm、横向φ200mm |

| 电加热系统 | 20个加热区,40~180℃可调 |

| Foil width | 20~1020毫米 |

| Press 1 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Press 2 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Press 3 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Servo motor power | 15KW/15KW/15KW |

| Full load wattage | 160KW |

| Air requirement | Air pressure: 0.6~0.7Mpa, Flow rate: >1m3/min |

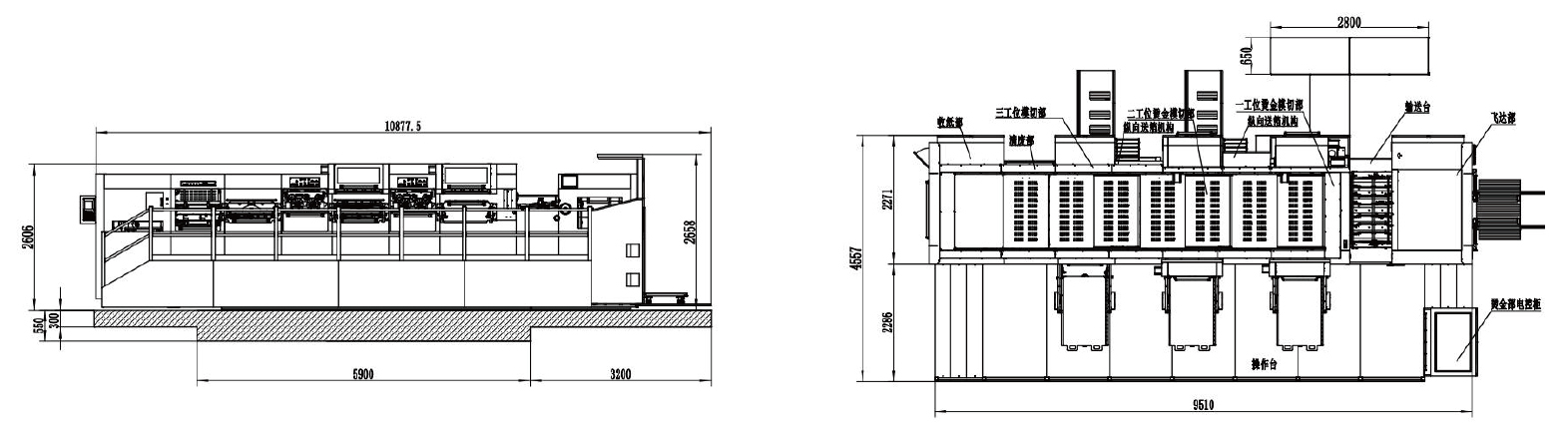

| 方面 | 10800×4586×2565mm |

| Dimension (die preloader included) | 10800×5086×2565mm |

| 重量 | 47吨 |

评价

目前还没有评价