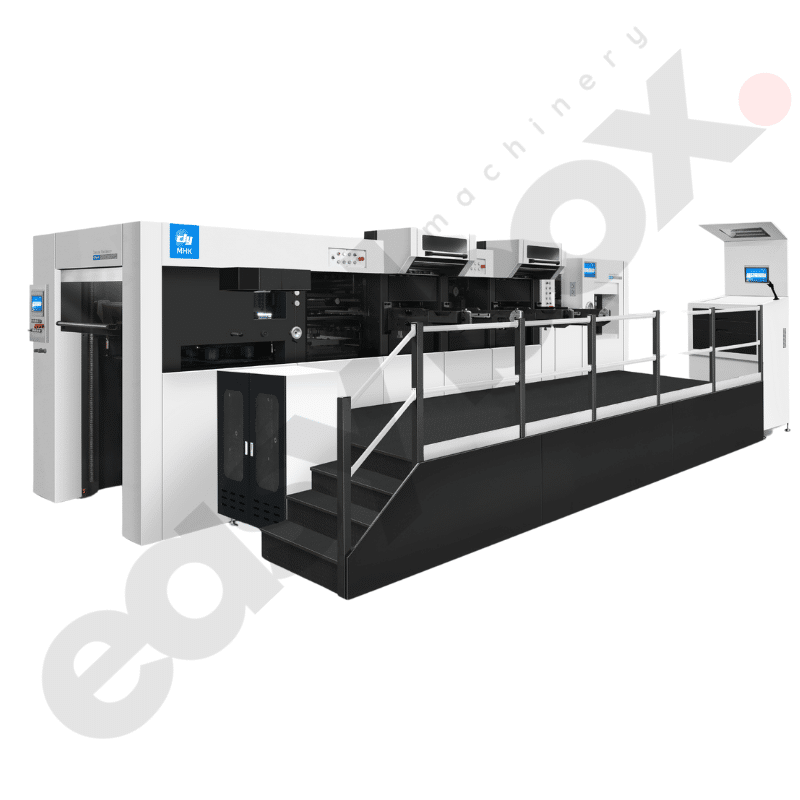

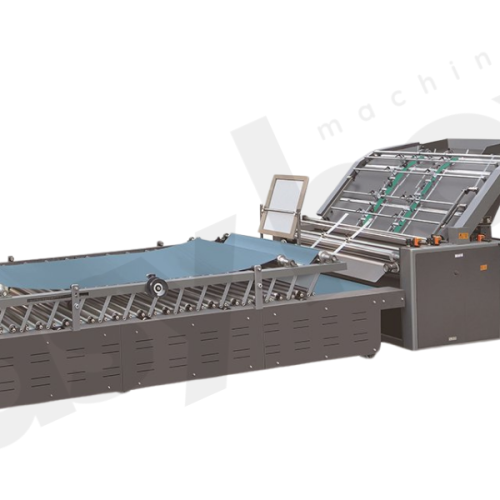

MHK 2S1050TT DUOPRESS 全自动高速双面烫金模切机

有存货

Did you like this product? Add to favorites now and follow the product.

Add to Wishlist

Add to Wishlist

有问题?请咨询专家(仅限 Whatsapp)

(+86) 158 9968 3398 WhatsApp 聊天

Product Description

绘画

Machine Parameters

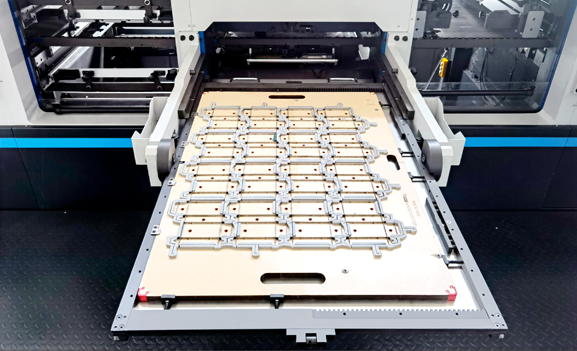

| 模型 | MHK-2S1050TT |

|---|---|

| 功能 | 1.烫印+烫印 |

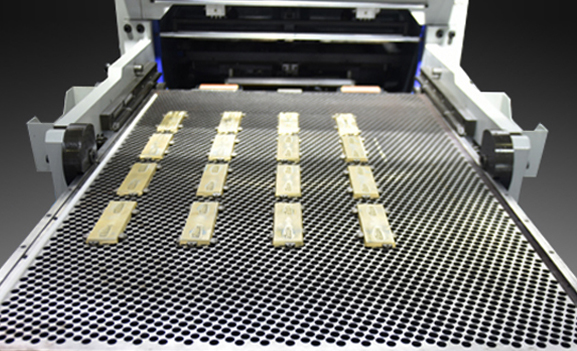

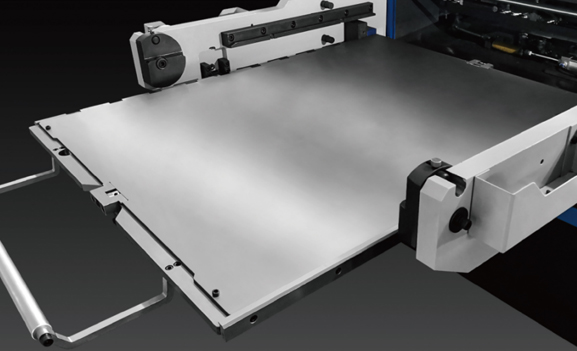

| 最大纸张尺寸 | 1050×750毫米 |

| 最小纸张尺寸 | 400×360毫米 |

| 最大切割尺寸 | 1040×720毫米 |

| 最大烫印尺寸 | 1040×720毫米 |

| 最大压花面积 | 1040×720毫米 |

| 最小夹持边缘 | 9~17毫米 |

| 内框尺寸 | 1140×755毫米 |

| 库存范围 | 纸张:80至2000g/m2,0.1~2mm,瓦楞纸板:最厚4mm |

| 模切精度 | ≤±0.075毫米 |

| 常见冲压精度 | ≤±0.075毫米 |

| 全息定位烫印精度 | ≤±0.075mm(可选) |

| 压花精度 | ≤±0.075毫米 |

| 最大模切力 | 压力机1:600T,压力机2:600T |

| 最大工作速度 | 7200s/h (模切), 7200s/h (烫印), 7200s/h (热压) |

| 最大进料堆高度 | 1600mm(带木托盘) |

| 最大收纸堆高度 | 1400mm(带木托盘) |

| 最大金箔直径 | 纵向Ф250mm、横向Ф200mm |

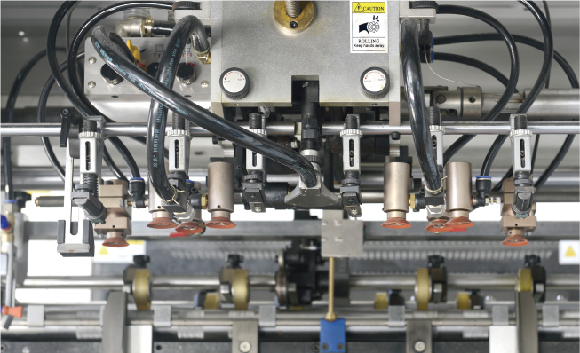

| 电加热系统 | 20个温度范围,40-180℃可调 |

| 箔宽度 | 20~1020毫米 |

| Press1 箔推进轴 | 3纵向+2横向(可选) |

| Press2 箔推进轴 | 3纵向+2横向(可选) |

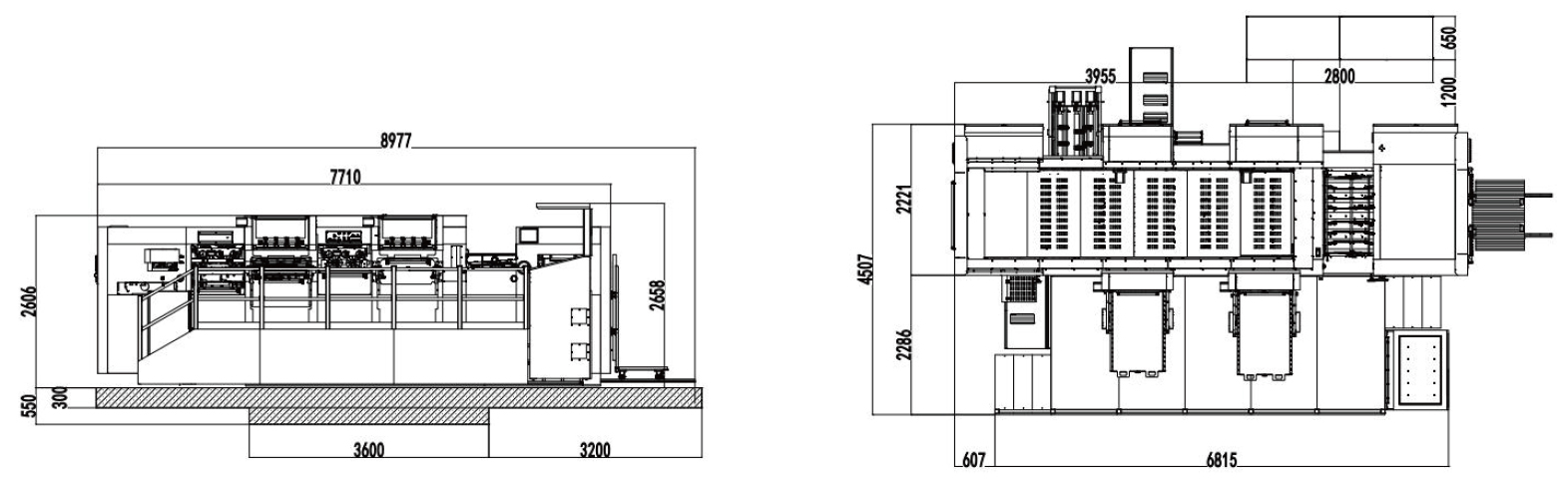

| 机器尺寸 | 8977×4507×2658mm(长×宽×高) (长:含备纸轨道,宽:含平台) |

| 机器净重 | 37T |

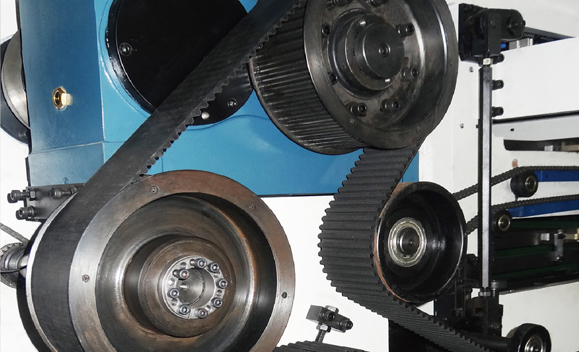

| 主电机功率 | 15千瓦 |

| 满载功率 | 114千瓦 |

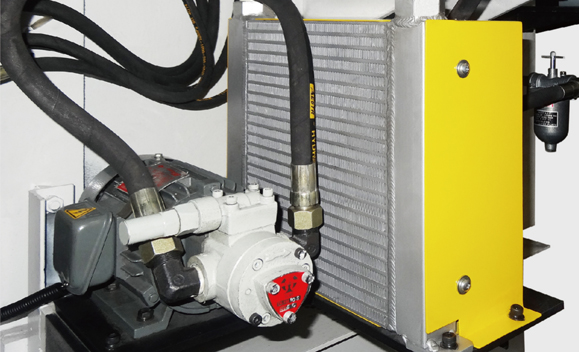

| 空气需求 | 压力:0.6~0.7Mpa,流量:≥1m3/min |

评价

目前还没有评价