Product Description

Introduction to the MHK 1300FC/1500FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder)

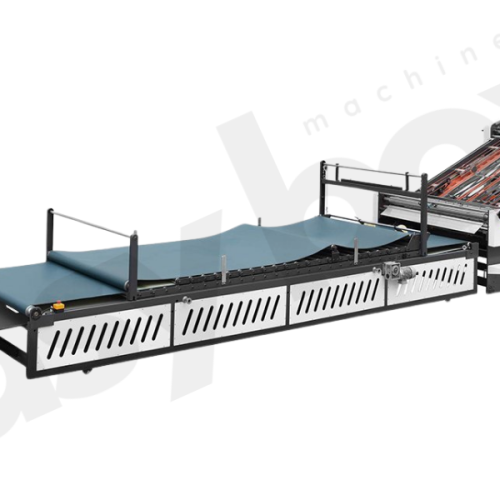

The MHK 1300FC/1500FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder) is an advanced solution designed to enhance precision and efficiency in the packaging and printing industries. This state-of-the-art machine integrates die cutting, creasing, and stripping functionalities with a lead edge feeder, ensuring superior performance and high productivity.

主要特征

高精度和准确度

The MHK 1300FC/1500FC delivers millimeter-perfect die cutting and creasing, making it ideal for applications requiring detailed and exact specifications. This high level of precision reduces material waste and ensures superior product quality, which is essential for maintaining high production standards.

前缘送料系统

The integrated lead edge feeder system ensures accurate and consistent feeding of materials, reducing the likelihood of misfeeds and enhancing the overall reliability and efficiency of the production process. This system is crucial for maintaining high-speed operations and ensuring reliable performance.

集成剥离功能

A standout feature of the MHK 1300FC/1500FC is its integrated stripping functionality. This system automatically removes waste material from the finished product, ensuring clean and precise edges. The stripping function reduces manual labor and speeds up the production process, leading to significant labor cost savings.

高速性能

Designed for high-speed operations, the MHK 1300FC/1500FC significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy.

好处

- 提高效率: The combination of high-speed operations, lead edge feeder system, and integrated stripping function streamlines the workflow, reducing downtime and labor costs.

- 用户友好的界面: 直观的触摸屏显示器提供简单的设置和实时监控,最大限度地减少操作员的学习曲线并确保顺利操作。

- 安全功能: 该机器配备紧急停止按钮和防护装置,确保安全的工作环境,符合最高行业标准。

应用

The MHK 1300FC/1500FC is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

结论

The MHK 1300FC/1500FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder) sets a new standard in the industry with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, this machine helps businesses increase productivity while maintaining high quality and safety standards.

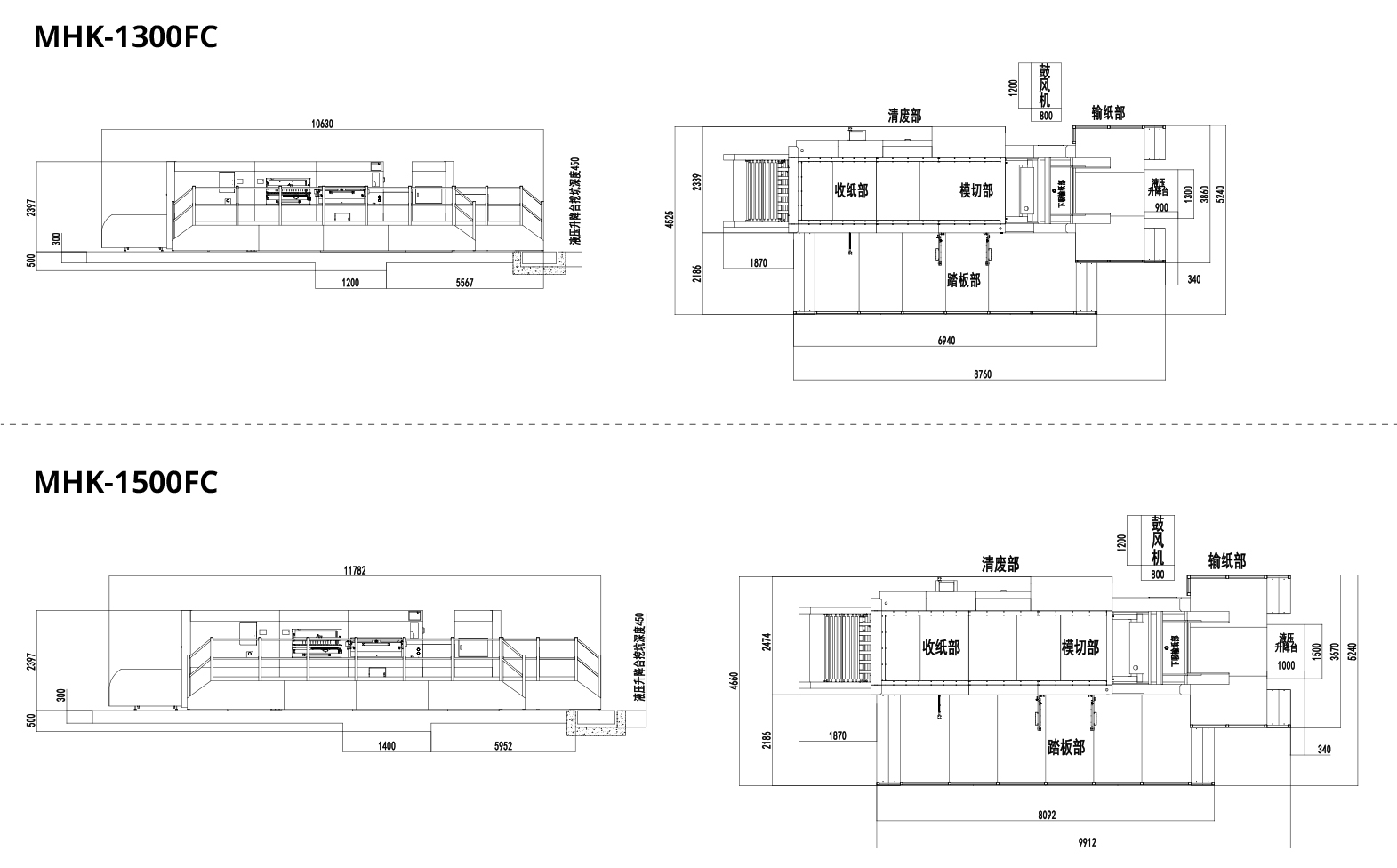

绘画

功能介绍

前缘送料器

顶部齿轮和精确的前缘进料器设计,能够对各种质量的瓦楞纸板进行一致进料。

新技术聚氨酯轮面配有网格升降器和气垫,确保送料平稳,即使板材翘曲也能准确对齐。

通过变频器进行精细的真空吸力调节,可适应从 F 瓦楞纸到双壁瓦楞纸的各种纸张。

纸张传输和对齐部分

可选择左侧和右侧推位以确保准确对齐。

先进的不停机调整送料时间,减少停机时间。

前规可不停地前后调节,以适应夹持器边缘的变化。

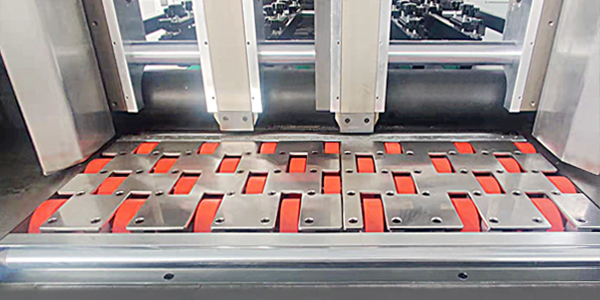

Die cutting section

Die cutting station safety door and pneumatic die chase safety locking system.

Air cushion underneath the cutting plate for easy sliding through.

Main drive adopts high quality precision worm gear and toggle system.

New technology of driving index with large motion angle to allow gripper bar gentle start and stop, less and smaller nicks required to achieve higher productivity. Equipped with overloading protection torque limit clutch.

Cutting pressure fine adjustment wheel with position indicate gauge.

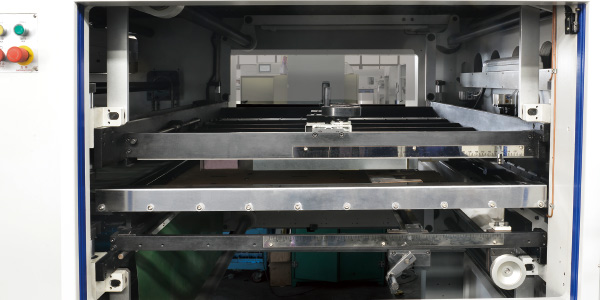

Stripping section

固定式中间清废板,加上零冲击力、平滑的上框运动曲线以及冲击瞬间的额外冲击力,可实现更干净的废料清除。

剥皮站出口处设有叼纸牙条定位块,保证剥皮的准确性。

中心线系统用于快速设置和更换剥线工具,与中心线兼容。

前端废料清除系统将废料边缘清除并通过传送带转移到机器外部。

夹持器边缘废料清除装置

夹持器边缘剥离和去除系统配有传送带,用于将夹持器边缘废料侧向去除到驱动侧。

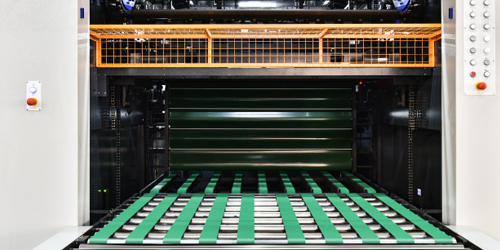

Paper counting & collecting section(Optional)

自动扶梯输送叉配合不停机气缸,将捆包整齐、正向地输送至皮带输送台。捆包输送台可与破碎机进一步连接,实现在线作业(订货时需提供)。

标准配置为电动批次计数器。

弹簧加载的可调链条张紧器可保持恒定的张力,从而减少链条上的压力并产生平稳的夹持杆运动。

Auto Non-stop Collecting Device(Optional)

自动润滑系统

采用集中自动润滑系统,确保各传动部件良好运转。

Machine Parameters

| 模型 | MHK-1500FC |

|---|---|

| 最大纸张尺寸 | 1500×1100毫米 |

| 最小纸张尺寸 | 480×480毫米 |

| 最大切割尺寸 | 1480×1080毫米 |

| 双切口最小宽度 | 12 毫米 |

| 最小夹持边缘 | 6-12毫米 |

| 切割规则高度 | 23.8 毫米 |

| 内框尺寸 | 1510×1120mm |

| 库存范围 | ≤8.5mm corrugated paper, E, B, C, A and AB corrugated paper |

| 最大工作速度 | 6000片/小时 |

| 最大模切力 | 400吨 |

| 移动下压板调节范围 | ±1.5毫米 |

| Max. Delivery Pile Height(Curtain type paper collection) | 1600mm(带木托盘) |

| Machine Dimensions(Curtain type paper collection) | 10490×5240×2800mm(L×W×H) (W: platform included) |

| Max. Delivery Pile Height(Stacking type paper collection) | Stacking type paper receiving (optional) |

| Machine Dimensions(Stacking type paper collection | 11782×5240×2397mm(L×W×H) (W: platform included) |

| 机器净重 | 25吨 |

| 主电机功率 | 15千瓦 |

| 满载功率 | 32千瓦 |

| 空气需求 | 压力:0.6~0.7Mpa,流量:≥0.37m3/min |

| 笔记 | 表中相同的特征写为一个。 |

评价

目前还没有评价