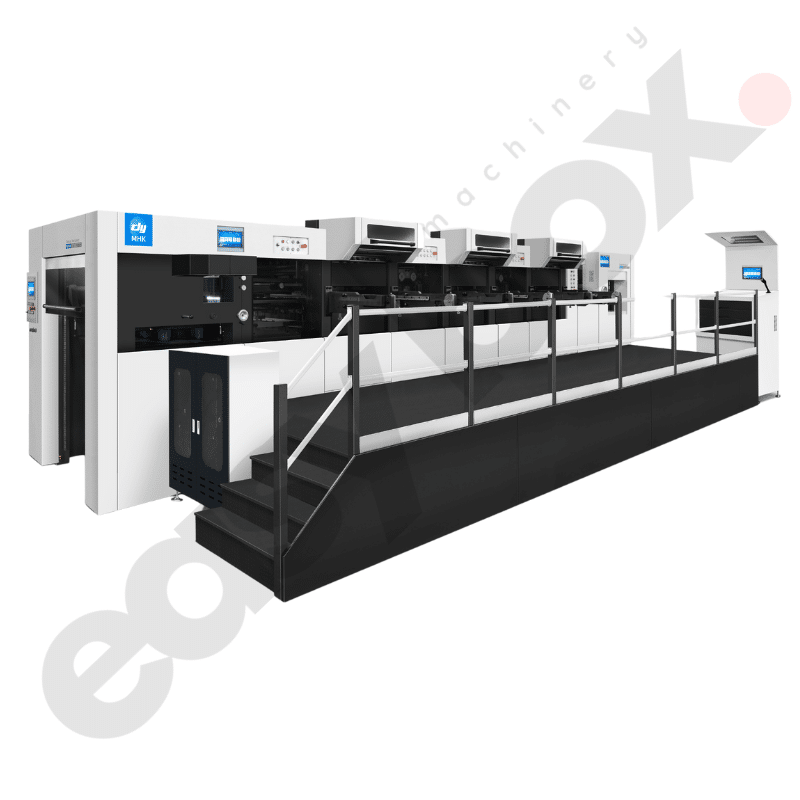

MHK 3S1050TTTC TRIOPRESS Otomatik Yüksek Hızlı Üçlü Sıcak Damgalama ve Kalıp Kesme Makinesi Soyma Özellikli

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

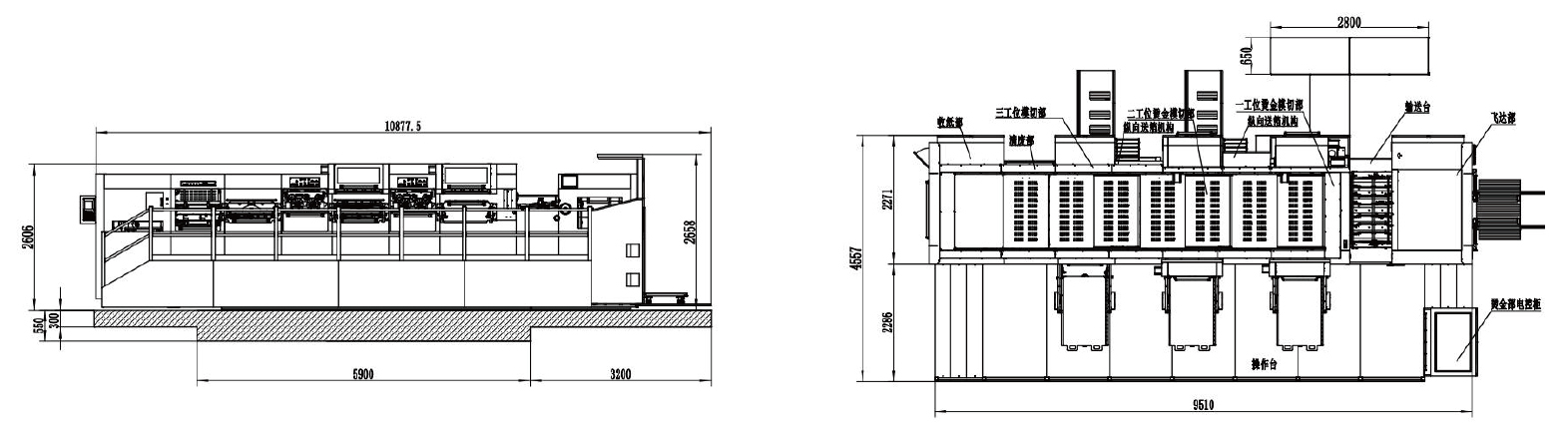

Çizim

MHK 3S1050TTTC TRIOPRESS Otomatik Yüksek Hızlı Üçlü Sıcak Damgalama ve Kalıp Kesme Makinesi Soyma Özelliğiyle: Üstün Hassasiyet ve Verimlilik

MHK 3S1050TTTC TRIOPRESS Otomatik Yüksek Hızlı Üçlü Sıcak Damgalama ve Soyma ile Kalıp Kesme Makinesi, modern baskı sonrası işlemlerin zorlu taleplerini karşılamak için tasarlanmış gelişmiş bir çözümdür. Birden fazla işlemi tek bir kusursuz işlemde birleştirerek, bu makine olağanüstü hassasiyet, verimlilik ve güvenilirlik sunar.

Temel Özellikler ve Avantajlar

Tek Geçişli Çoklu İşlem Yeteneği

MHK 3S1050TTTC TRIOPRESS, tek geçişte birden fazla işlem gerçekleştirebilir, üretim verimliliğini önemli ölçüde artırabilir ve işçilik maliyetlerini azaltabilir. Makinenin yetenekleri şunları içerir:

- Sıcak Damgalama + Sıcak Damgalama + Sıcak Damgalama: Tek geçişte karmaşık ve yüksek kaliteli üçlü folyo tasarımları elde edin.

- Sıcak Damgalama + Sıcak Damgalama + Derin Kabartma: Gelişmiş doku ve detay için çift folyo damgalamayı derin kabartmayla birleştirin.

- Sıcak Damgalama + Sıcak Damgalama + Kalıp Kesim: Daha akıcı bir süreç için çift folyo damgalamayı hassas kalıp kesimiyle birleştirin.

- Sıcak Damgalama + Derin Kabartma + Kalıp Kesim: Tek bir işlemde folyo damgalama, derin kabartma ve kalıp kesme ile ürünlerinizi geliştirin.

- Derin Kabartma + Derin Kabartma + Derin Kabartma: Üstün doku ve detay için çoklu derin kabartma efektleri elde edin.

- Sıcak Damgalama + Sıcak Damgalama + Kalıp Kesim + Sıyırma: Tek bir kusursuz işlemde çift folyo damgalama, kalıp kesme ve etkili sıyırma işlemlerini gerçekleştirin.

- Sıcak Damgalama + Derin Kabartma + Kalıp Kesim + Sıyırma: Yüksek kaliteli yüzeyler için folyo damgalama, derin kabartma, kalıp kesme ve sıyırma işlemlerini birleştirin.

- Derin Kabartma + Derin Kabartma + Kalıp Kesim + Sıyırma: Üstün sonuçlar için çoklu derin kabartma işlemlerini kalıp kesme ve sıyırma ile birleştirin.

Hassasiyet ve Verimlilik

MHK 3S1050TTTC TRIOPRESS, geleneksel makineler ve duopress makinelerinin çoğu zaman eşleşemediği bir yetenek olan, tek geçişte birden fazla işlemi doğru bir şekilde kaydetme yeteneğiyle öne çıkar. Bu hassasiyet, yüksek kaliteli sonuçlar sağlar ve üretim verimliliğini en üst düzeye çıkarır.

Sağlam Yapı ve Tasarım

Yüksek kaliteli malzemelerden üretilen MHK 3S1050TTTC, dayanıklılık ve sağlamlık için üretilmiştir. Ağır hizmet tipi yapısı, sürekli çalışma sırasında güvenilir performans garanti eder ve onu yüksek hacimli üretim görevleri için uygun hale getirir.

Kullanıcı Dostu Arayüz

Makine, operatörlerin parametreleri kolayca ayarlayıp ayarlamasına, üretim sürecini izlemesine ve sorunları gidermesine olanak tanıyan sezgisel bir kullanıcı arayüzüne sahiptir. Bu kullanıcı dostu tasarım, üretkenliği artırır ve yeni operatörler için öğrenme eğrisini azaltır.

Verimli Soyma Sistemi

Verimli soyma sistemi atık malzemeyi otomatik olarak kaldırarak üretim sürecini hızlandırır ve manuel müdahale ihtiyacını azaltır. Bu özellik verimliliği artırır, daha temiz bir üretim ortamı sağlar ve bitmiş ürünlerin genel kalitesini iyileştirir.

Güvenlik Özellikleri

MHK 3S1050TTTC'de güvenlik en önemli önceliktir. Makine, acil durdurma düğmeleri, güvenlik korumaları ve potansiyel tehlikeleri algılayıp bunlara yanıt veren sensörler dahil olmak üzere birden fazla güvenlik mekanizmasıyla donatılmıştır ve tüm kullanıcılar için güvenli bir çalışma sağlar.

Çok Yönlü Uygulamalar

MHK 3S1050TTTC çok yönlüdür ve kağıt, karton, plastik levhalar ve daha fazlası dahil olmak üzere çok çeşitli malzemeleri işleyebilir. Uyarlanabilirliği onu aşağıdakiler dahil olmak üzere çeşitli endüstriler için mükemmel bir seçim haline getirir:

- Baskı: Baskılı materyaller için yüksek kalitede damgalama, kabartma ve kesim hizmeti sunuyoruz.

- Ambalajlama: Ambalaj malzemeleri için hassas kalıp kesimi, folyo damgalama ve sıyırma hizmeti sunuyoruz.

- Etiketler ve Etiketler: Etiketler ve taglar için detaylı ve ilgi çekici tasarımlar oluşturmak.

- Dekoratif Uygulamalar: Dekoratif ürünleri karmaşık kesimler, folyo vurguları ve kabartmalarla zenginleştirmek.

Gelişmiş Üretkenlik

Yüksek hızlı çalışma, üçlü sıcak damgalama, derin kabartma, kalıp kesme ve soyma işlevlerinin tek bir makinede birleştirilmesi genel üretkenliği artırır. Bu kombinasyon, duruş süresini azaltır, manuel müdahaleyi en aza indirir ve tüm üretim çalışmalarında tutarlı kaliteyi garanti eder.

Teknolojik Gelişmeler

MHK 3S1050TTTC TRIOPRESS, servo hassas kontrol sistemleri ve otomatik işlevler dahil olmak üzere gelişmiş teknolojik özellikleri bünyesinde barındırmaktadır. Bu yenilikler üretim sürecini kolaylaştırır, duruş süresini azaltır ve verimliliği artırır, bu da bu makineyi modern üretim operasyonları için değerli bir varlık haline getirir.

Çözüm

MHK 3S1050TTTC TRIOPRESS Otomatik Yüksek Hızlı Üçlü Sıcak Damgalama ve Kalıp Kesme Makinesi, Soyma ile hassasiyet, hız ve gelişmiş otomasyonun üstün bir kombinasyonunu sunar. Sağlam yapısı, kullanıcı dostu arayüzü ve çok yönlü uygulamaları, baskı sonrası süreçlerini geliştirmek isteyen işletmeler için mükemmel bir yatırım olmasını sağlar. İster baskı, ister paketleme veya dekoratif uygulamalar için olsun, MHK 3S1050TTTC olağanüstü performans ve güvenilirlik sunarak günümüzün endüstriyel ortamlarının yüksek taleplerini karşılar.

Kısmi Giriş

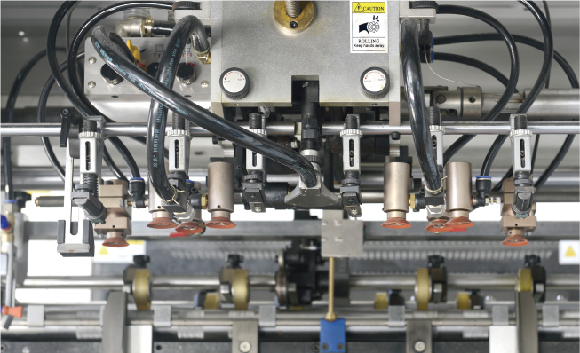

Besleyici ünitesi

Farklı türdeki malzemeleri işlemek için açı ayarlamalı dört alma ve dört ileri emme kafası.

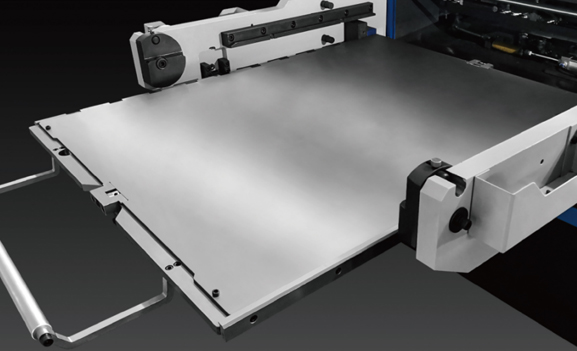

Beslenme masası

Üretim esnasında levhanın ön tarafa doğru konumlandırılmasını elle ayarlamak için senkronizasyon cihazı, Levha tutma cihazı (levhaları ön tarafa doğru yönlendirir).

Sıcak damgalama bölümü

Verimli ve doğru sıcaklık kontrolü için her biri ayrı ayrı ayarlanabilen 20 ısıtma bölgeli ısıtma tabanı.

Folyo ilerletme ünitesi

Üç set uzunlamasına folyo ilerletme şaftı ve iki set yanal folyo ilerletme şaftı, kısa ve uzun folyo adımları için ayrı ayrı programlanabilen servo motorlarla tahrik edilmektedir.

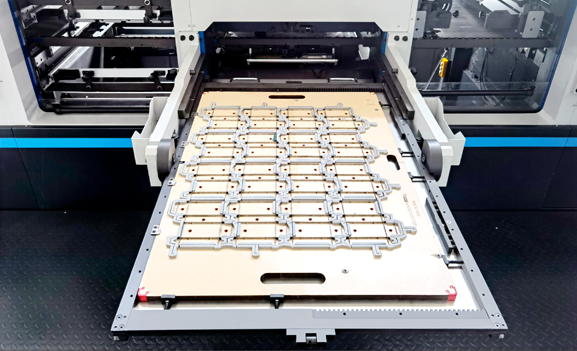

Kalıp hızlı kilitleme cihazı

Hazırlanma süresini kısaltmak için Center-line sistemini ve hızlı kilitleme cihazını kullanın.

Tabak ayarı

15 mm hassas zemin destekli taban plakasının üstünde 5 mm sertleştirilmiş damgalama plakası veya 3,5 mm + 1,5 mm sandviç damgalama plakası, hem çalışma hem de çapraz yönde +/- 0,9 mm mikro ayar ile hızlı kurulum ve kolay hazırlama.

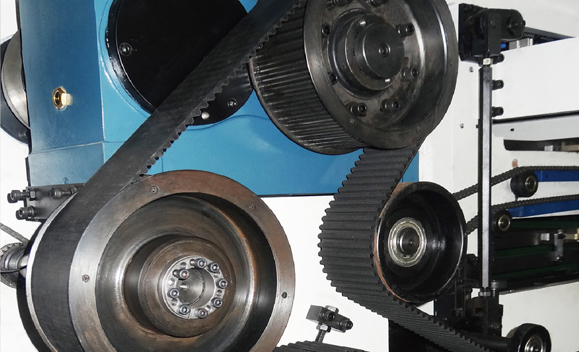

Tork sınırlayıcı

Tayvan'ın yüksek hassasiyetli aralıklı segmentasyonu, uzun süreli kullanımda yüksek konumsal hassasiyet sağlar.

Tayvan tork sınırlayıcı, hassas sınır koruma performansıyla insan ve makine güvenliğini garanti altına almak için yapay çalışma kazalarını doğru bir şekilde koruyabilir.

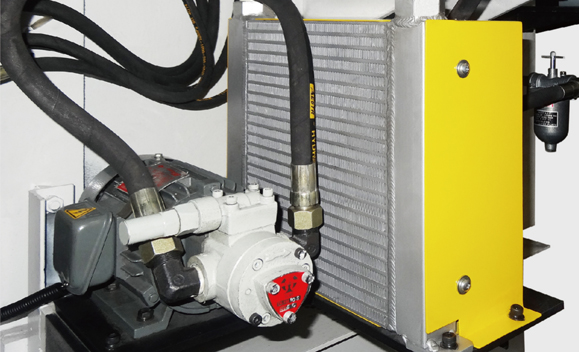

Ana motor yağlama sistemi

Ana motorun uzun süre yüksek hızda yağlanmasını sağlamak için Tayvan yapımı otomatik yağ pompası soğutma sirkülasyon sistemi.

Yağ basınç göstergesi ve yağ basınç alarm cihazı ile donatılmıştır.

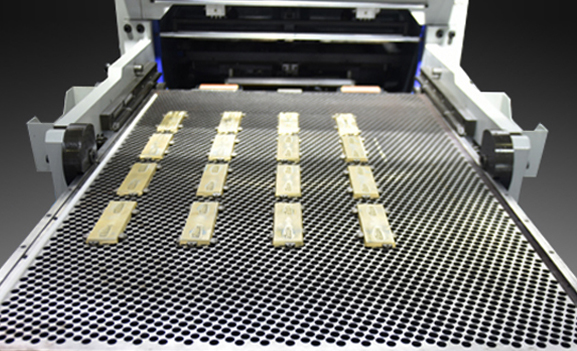

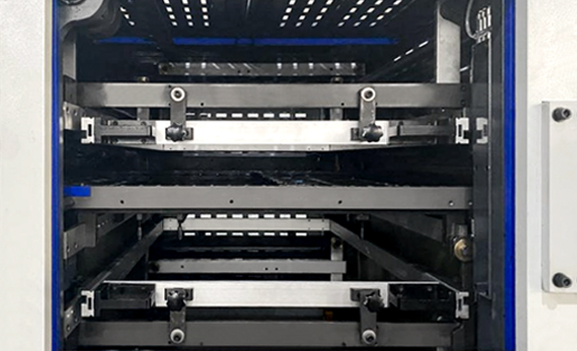

Soyma ünitesi

Merkez hattı sistemini benimseyin, Üst ve alt soyma aleti montaj çerçevesi iş kurulumu ve hazır hale getirmek için dışarı çekilebilir.

Tutma kenarı atık giderme cihazı

Tutucu kenar sıyırma ve çıkarma sistemi, tutucu kenar atıklarını yanlara doğru tahrik tarafına çıkarmak için konveyör bant ile çalışır.

Teslimat ünitesi

Kesintisiz perdeli otomatik teslimat. Bu perde, yığın değişimi sırasında gelen sayfaları yakalamak için teslimata hareket eder. Kağıt toplama için iki üfleyici, ince ve kalın kağıtların düzgün bir şekilde toplanmasını sağlayabilir.

Almanya vakum pompası

Almanya Becker yağsız üfleme ve vakum pompası.

Otomatik yağlama sistemi

Tahrik edilen parçaların daha iyi çalışmasını sağlamak için yoğunlaştırılmış otomatik yağlama sistemini benimseyin.

Ek bilgi

| Örnek | MHK-3S1050TTTC |

|---|---|

| İşlev | 1. sıcak damgalama+sıcak damgalama+sıcak damgalama |

| Maksimum sayfa boyutu | 1050×750mm |

| Min.sayfa boyutu | 400×360mm |

| Max.kalıp kesme boyutu | 1040×720mm |

| Maksimum sıcak damgalama boyutu | 1040×720mm |

| Kavrayıcı marjı | 9~17mm |

| İç kovalamaca boyutu | 1080×745mm |

| Stok aralığı | 80~2000g/m2 Karton, 0.1~2mm Karton, ≤4mm Oluklu |

| Kalıp kesme hassasiyeti | ≤±0,075 mm |

| Ortak damgalama doğruluğu | ≤±0,075 mm |

| Hologram konumlandırma damgalama doğruluğu | ≤±0,075 mm |

| Maksimum kalıp kesme kuvveti | 600 ton + 600 ton + 600 ton |

| Maksimum çalışma hızı | 6200s/saat |

| Maksimum besleyici yığın yüksekliği (ahşap palet dahil) | 1600mm |

| Maksimum teslimat yığın yüksekliği (ahşap palet dahil) | 1400mm |

| Max.altın folyo çapı | Φ250mm Boyuna, Φ200mm Enine |

| Elektrikle ısıtmalı sistem | 20 Isıtma bölgesi, 40~180℃ Ayarlanabilir |

| Folyo genişliği | 20~1020mm |

| 1. folyo ileri millerine basın | 3 Boyuna + 2 Enine (Opsiyonel) |

| 2 folyo ileri şaftına basın | 3 Boyuna + 2 Enine (Opsiyonel) |

| 3 folyo ileri şaftına basın | 3 Boyuna + 2 Enine (Opsiyonel) |

| Servo motor gücü | 15KW/15KW/15KW |

| Tam yük watt değeri | 160 kW |

| Hava ihtiyacı | Hava basıncı: 0,6~0,7Mpa, Debi: >1m3/dak |

| Boyut | 10800×4586×2565mm |

| Boyut (kalıp ön yükleyici dahil) | 10800×5086×2565mm |

| Ağırlık | 47T |

İncelemeler

Henüz yorum yapılmadı.