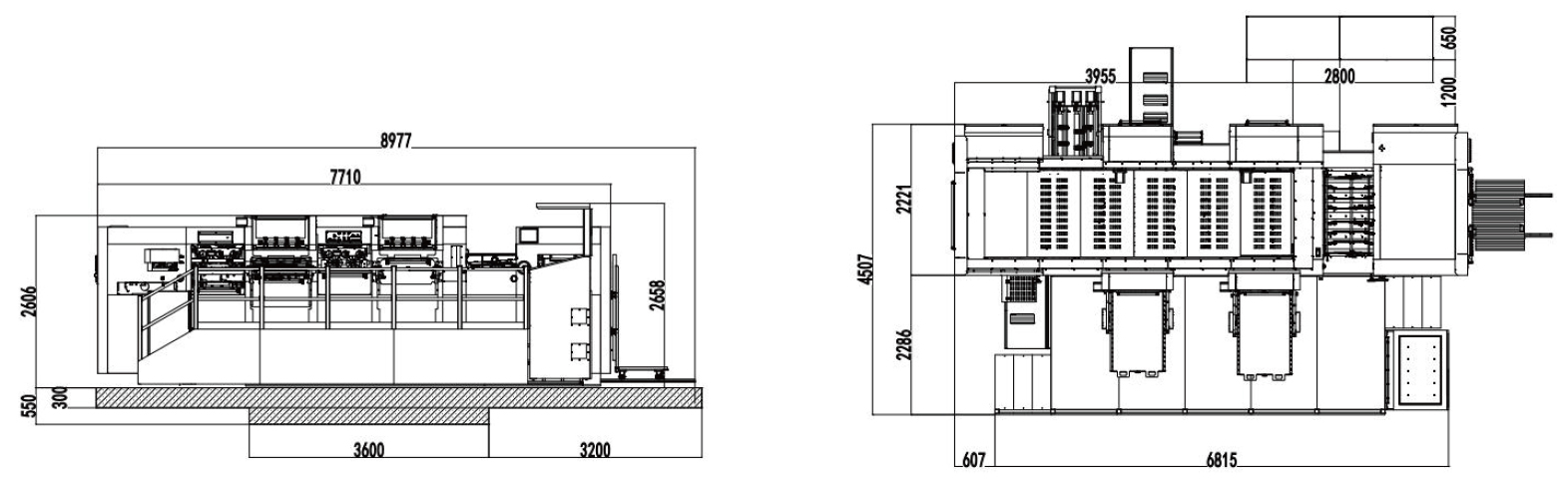

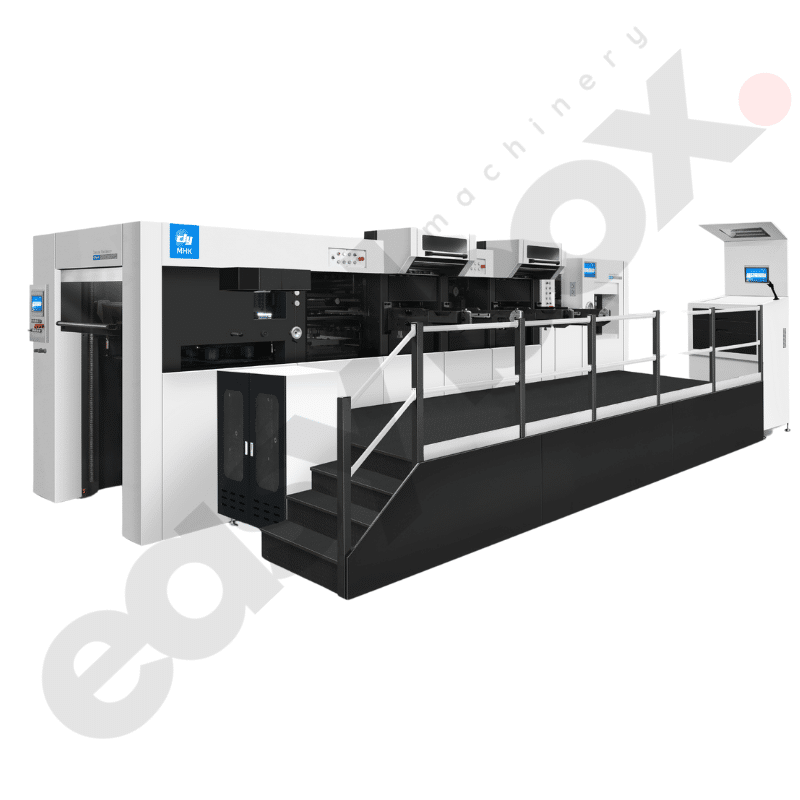

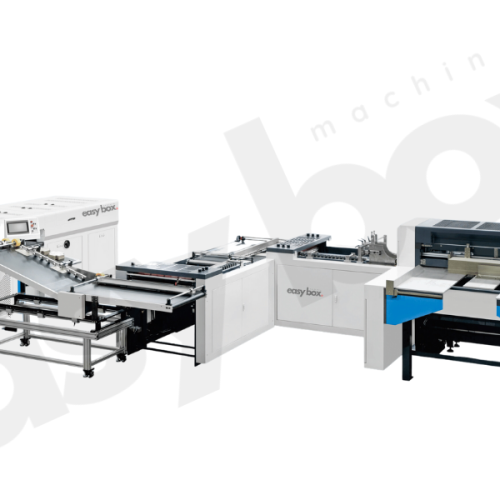

MHK 2S1050TTC DUOPRESS Otomatik Yüksek Hızlı Çift Folyo Damgalama ve Kalıp Kesme Makinesi, Soyma Özelliğiyle: Baskı Sonrası İşlemlerde Devrim Yaratıyor

MHK 2S1050TTC DUOPRESS Otomatik Yüksek Hızlı Çift Folyo Damgalama ve Soyma ile Kalıp Kesme Makinesi, modern baskı sonrası işlemlerin yüksek taleplerini karşılamak üzere tasarlanmıştır. Birden fazla işlemi tek bir kusursuz işlemde birleştirerek, bu makine eşsiz verimlilik, doğruluk ve değer sunar.

Temel Özellikler ve Avantajlar

Tek Geçişli Çoklu İşlem Yeteneği

MHK 2S1050TTC, tek geçişte birden fazla işlem gerçekleştirebilir, üretim verimliliğini önemli ölçüde iyileştirebilir ve işçilik maliyetlerini azaltabilir. Makinenin yetenekleri şunları içerir:

- Sıcak Damgalama + Sıcak Damgalama: Çift damgalama ile karmaşık ve yüksek kaliteli folyo tasarımları elde edin.

- Sıcak Damgalama + Derin Kabartma: Gelişmiş doku ve detay için sıcak damgalamayı derin kabartmayla birleştirin.

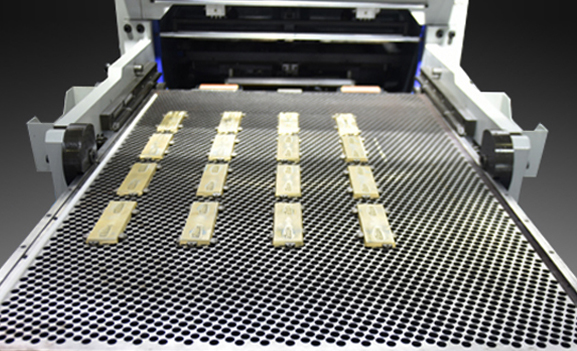

- Sıcak Damgalama + Kalıp Kesim + Sıyırma: Tek bir kusursuz işlemde folyo damgalama, hassas kalıp kesimi ve etkili sıyırma işlemini gerçekleştirin.

- Derin Kabartma + Kalıp Kesim + Sıyırma: Üstün bir sonuç için derin kabartmayı kalıp kesme ve sıyırma ile birleştirin.

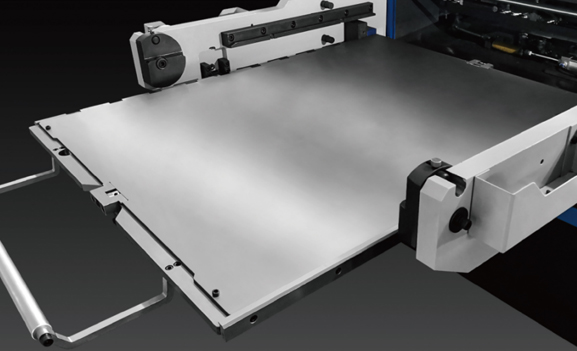

Hassasiyet ve Verimlilik

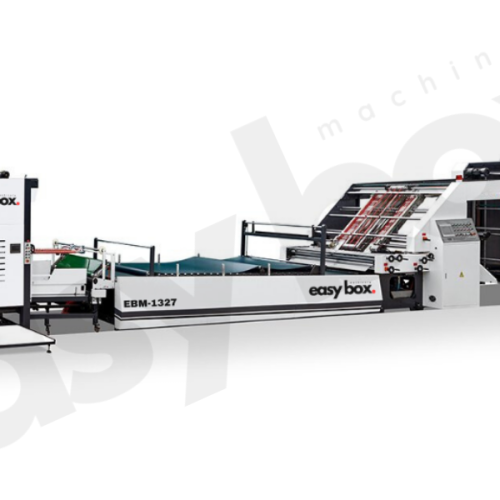

MHK 2S1050TTC DUOPRESS, folyolama ve kalıp kesme işlemlerini tek geçişte doğru bir şekilde kaydetme yeteneğiyle öne çıkıyor; bu, genellikle geleneksel makinelerin yeteneklerinin ötesindedir. Bu hassasiyet, yüksek kaliteli sonuçlar sağlar ve üretim verimliliğini en üst düzeye çıkarır.

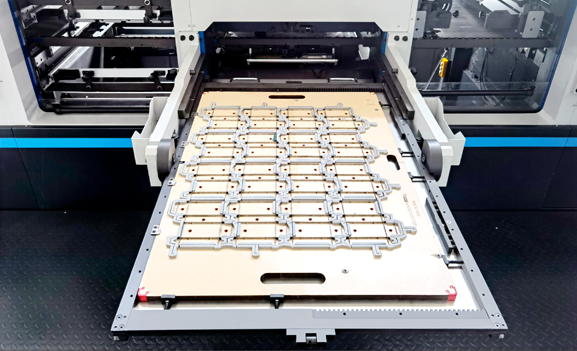

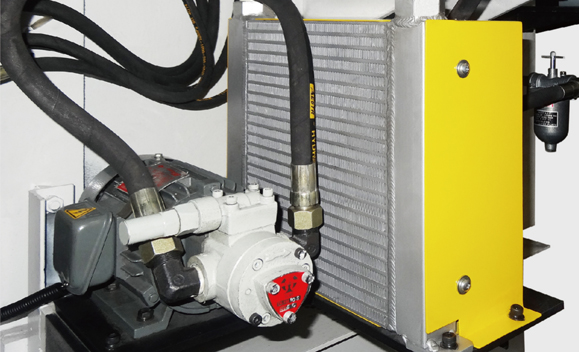

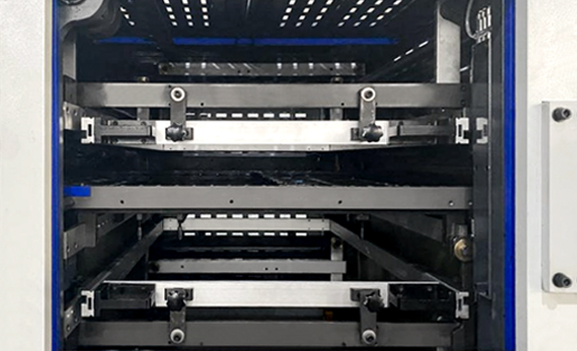

Sağlam Yapı ve Tasarım

Yüksek kaliteli malzemelerden üretilen MHK 2S1050TTC, dayanıklılık ve sağlamlık için üretilmiştir. Ağır hizmet tipi yapısı, sürekli çalışma sırasında güvenilir performans garanti eder ve onu yüksek hacimli üretim görevleri için uygun hale getirir.

Kullanıcı Dostu Arayüz

Makine, operatörlerin parametreleri kolayca ayarlayıp ayarlamasına, üretim sürecini izlemesine ve sorunları gidermesine olanak tanıyan sezgisel bir kullanıcı arayüzüne sahiptir. Bu kullanıcı dostu tasarım, üretkenliği artırır ve yeni operatörler için öğrenme eğrisini azaltır.

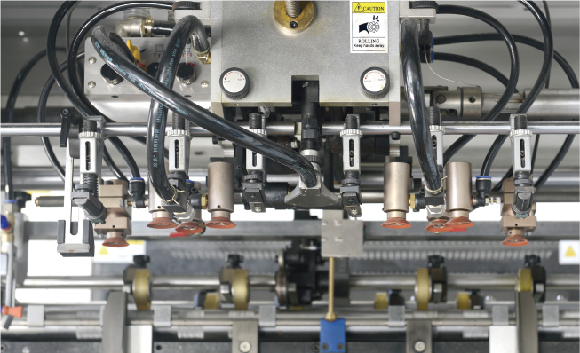

Güvenlik Özellikleri

MHK 2S1050TTC'de güvenlik en önemli önceliktir. Makine, acil durdurma düğmeleri, güvenlik korumaları ve potansiyel tehlikeleri algılayıp bunlara yanıt veren sensörler dahil olmak üzere birden fazla güvenlik mekanizmasıyla donatılmıştır ve tüm kullanıcılar için güvenli bir çalışma sağlar.

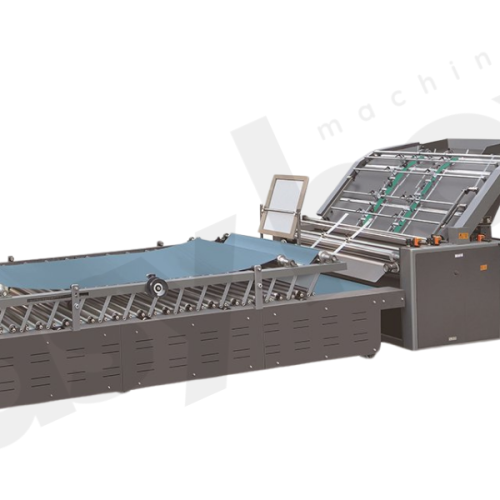

Çok Yönlü Uygulamalar

MHK 2S1050TTC çok yönlüdür ve kağıt, karton, plastik levhalar ve daha fazlası dahil olmak üzere çok çeşitli malzemeleri işleyebilir. Uyarlanabilirliği onu aşağıdakiler dahil olmak üzere çeşitli endüstriler için mükemmel bir seçim haline getirir:

- Baskı: Baskılı materyaller için yüksek kalitede damgalama, kabartma ve kesim hizmeti sunuyoruz.

- Ambalajlama: Ambalaj malzemeleri için hassas kalıp kesimi, folyo damgalama ve sıyırma hizmeti sunuyoruz.

- Etiketler ve Etiketler: Etiketler ve taglar için detaylı ve ilgi çekici tasarımlar oluşturmak.

- Dekoratif Uygulamalar: Dekoratif ürünleri karmaşık kesimler, folyo vurguları ve kabartmalarla zenginleştirmek.

Gelişmiş Üretkenlik

Yüksek hızlı çalışma, çift folyo damgalama, derin kabartma, kalıp kesme ve sıyırma işlevlerinin tek bir makinede bir araya getirilmesi genel üretkenliği artırır. Bu kombinasyon, duruş süresini azaltır, manuel müdahaleyi en aza indirir ve tüm üretim çalışmalarında tutarlı kaliteyi garanti eder.

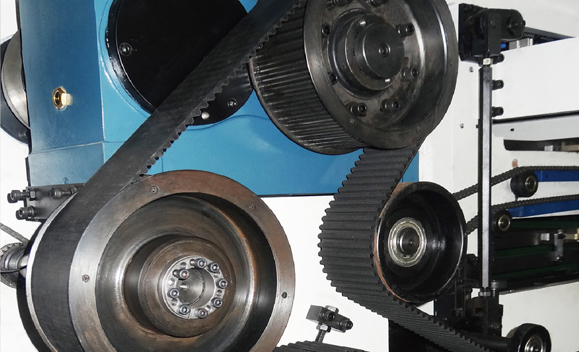

Teknolojik Gelişmeler

MHK 2S1050TTC DUOPRESS, servo hassas kontrol sistemleri ve otomatik işlevler dahil olmak üzere gelişmiş teknolojik özellikleri bünyesinde barındırmaktadır. Bu yenilikler üretim sürecini kolaylaştırır, duruş süresini azaltır ve verimliliği artırır, bu da bu makineyi modern üretim operasyonları için değerli bir varlık haline getirir.

Çözüm

MHK 2S1050TTC DUOPRESS Otomatik Yüksek Hızlı Çift Folyo Damgalama ve Kalıp Kesme Makinesi, Soyma ile hassasiyet, hız ve gelişmiş otomasyonun benzersiz bir kombinasyonunu sunar. Sağlam yapısı, kullanıcı dostu arayüzü ve çok yönlü uygulamaları, baskı sonrası süreçlerini geliştirmek isteyen işletmeler için mükemmel bir yatırım olmasını sağlar. İster baskı, ister paketleme veya dekoratif uygulamalar için olsun, MHK 2S1050TTC olağanüstü performans ve güvenilirlik sunarak günümüzün endüstriyel ortamlarının yüksek taleplerini karşılar.

İncelemeler

Henüz yorum yapılmadı.