MHK 1300FC/1500FC Ayna Makineleri Çift Kesim Çalışma İstasyonu (Uç Kenar Besleyici)

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

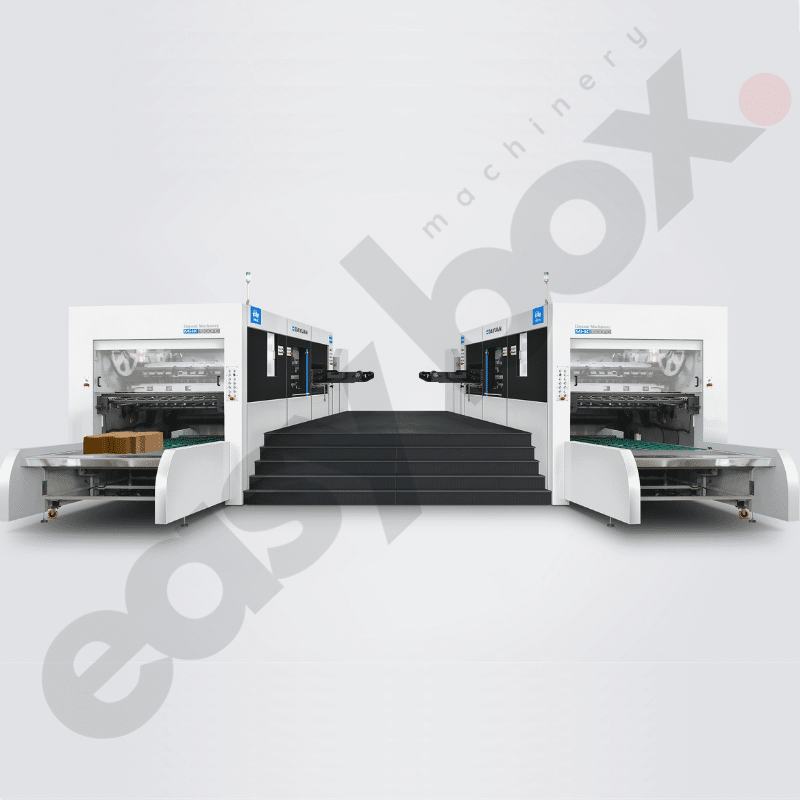

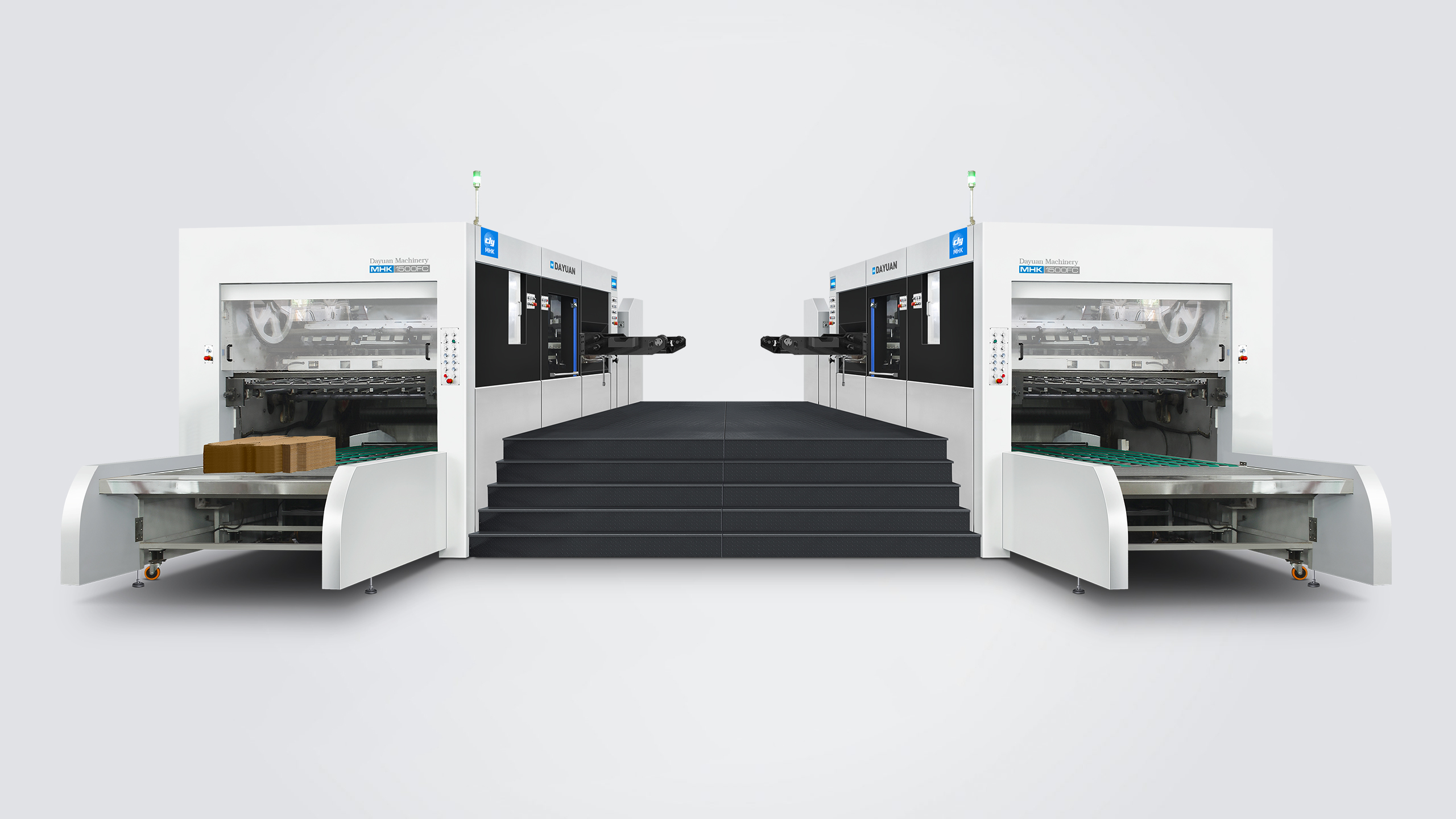

MHK 1300FC/1500FC Ayna Makineleri Çift Kesim Çalışma İstasyonuna (Uç Kenar Besleyici) Giriş

MHK 1300FC/1500FC Ayna Makineleri Çift Kesim Çalışma İstasyonu, Ön Kenar Besleyici ile paketleme ve baskı endüstrilerinde verimliliği ve hassasiyeti artırmak için tasarlanmış gelişmiş bir çözümdür. Bu yenilikçi makine, çift kesim istasyonlarını bir ön kenar besleyici ile birleştirerek üstün performans, yüksek üretkenlik ve modern üretim ortamlarında kusursuz entegrasyon sağlar.

Temel Özellikler

Çift Kalıp Kesici Entegrasyonu

MHK 1300FC/1500FC, aynı anda çalışan çift kalıp kesme istasyonlarına sahiptir ve üretim hızını ve verimini önemli ölçüde artırır. Bu çift entegrasyon, yüksek hacimli üretim taleplerinin verimli bir şekilde ele alınmasını sağlayarak genel üretim süresini ve maliyetlerini azaltır.

Ön Kenar Besleme Sistemi

Entegre ön kenar besleme sistemi, yüksek hızlı operasyonları sürdürmek ve yanlış besleme olasılığını azaltmak için çok önemli olan doğru ve tutarlı malzeme beslemesini sağlar. Bu sistem, üretim sürecinin genel güvenilirliğini ve verimliliğini artırır.

Yüksek Hassasiyet ve Doğruluk

Bu makineler milimetrelik mükemmellikte kalıp kesimi sunar ve bu da onları ayrıntılı ve kesin özellikler gerektiren uygulamalar için ideal hale getirir. Yüksek hassasiyet, malzeme israfını en aza indirir ve yüksek üretim standartlarını korumak için olmazsa olmaz olan üstün ürün kalitesini garanti eder.

Entegre Soyma Fonksiyonu

MHK 1300FC/1500FC, bitmiş üründen atık malzemeyi otomatik olarak çıkaran entegre bir soyma işlevi içerir. Bu özellik temiz ve hassas kenarlar sağlar, manuel işçiliği azaltır ve üretim sürecini hızlandırarak önemli işçilik maliyeti tasarruflarına yol açar.

Faydalar

- Gelişmiş Verimlilik: Çift kalıp kesme istasyonu, yüksek hızlı operasyonlar ve entegre sıyırma fonksiyonunun birleşimi iş akışını kolaylaştırır, duruş süresini ve işçilik maliyetlerini azaltır.

- Kullanıcı Dostu Arayüz: Sezgisel dokunmatik ekran, kolay kurulum ve gerçek zamanlı izleme olanağı sunarak operatörler için öğrenme eğrisini en aza indirir ve sorunsuz bir çalışma sağlar.

- Güvenlik Özellikleri: Acil durdurma düğmeleri ve koruyucu muhafazalarla donatılan makine, en yüksek endüstri standartlarına bağlı kalarak güvenli bir çalışma ortamı sağlar.

Uygulamalar

MHK 1300FC/1500FC, paketleme, etiketler, tabelalar ve özel baskı malzemeleri dahil olmak üzere çeşitli uygulamalar için mükemmeldir. Çok yönlülüğü, hassasiyeti ve verimliliği, üretim süreçlerini optimize etmek ve yüksek hacimli talepleri karşılamak isteyen işletmeler için onu değerli bir varlık haline getirir.

Çözüm

MHK 1300FC/1500FC Ayna Makineleri Çift Kesim Çalışma İstasyonu, Ön Kenar Besleyici ile hassasiyet, hız ve verimlilik kombinasyonuyla yeni bir endüstri standardı belirliyor. Modern üretim taleplerini karşılamak üzere tasarlanan bu makineler, işletmelerin yüksek kalite ve güvenlik standartlarını korurken üretkenliğini artırmasına yardımcı olur.

Alan Tasarrufu

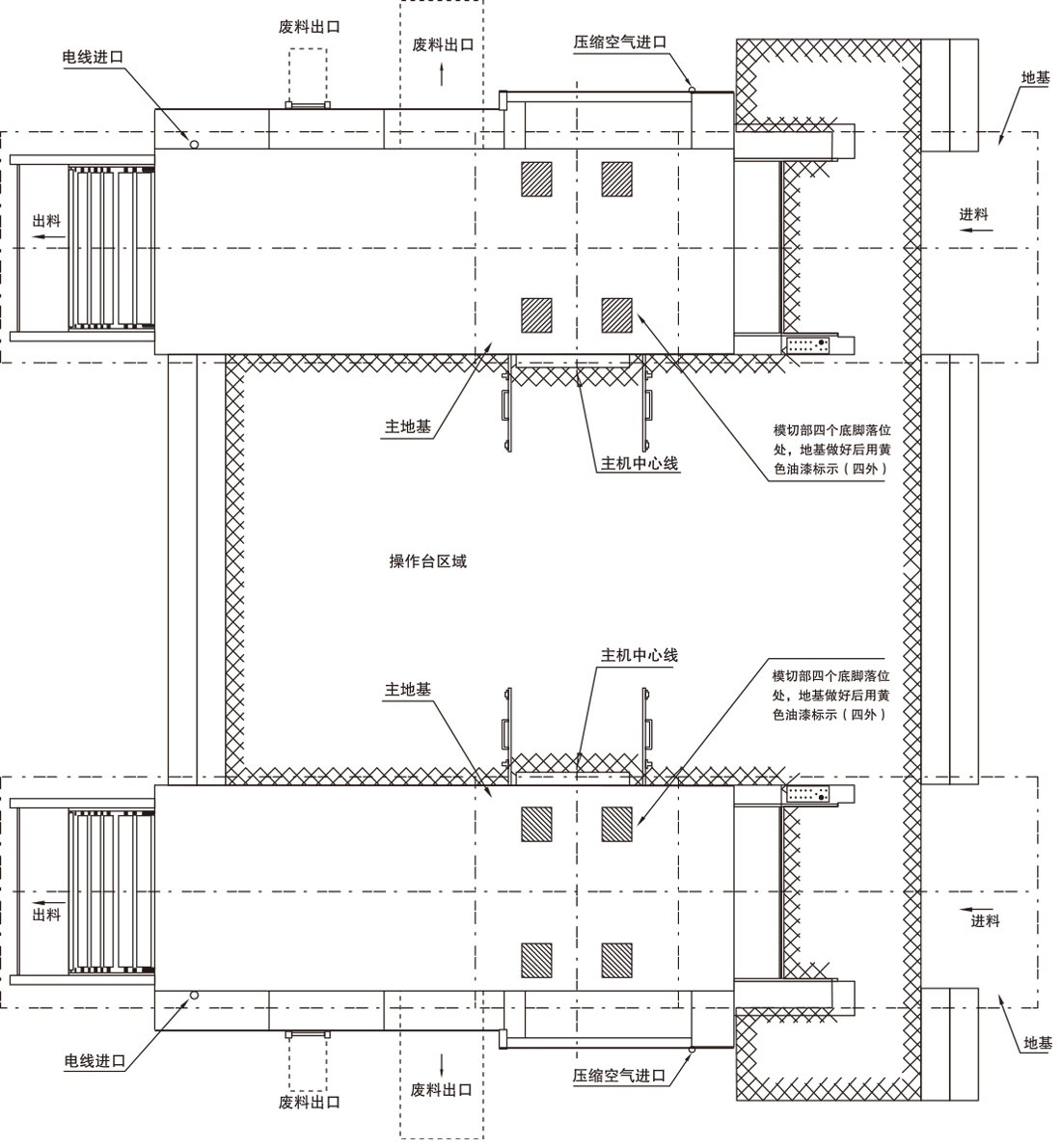

| 2 Normal Makine Zemin Alanı | Ayna Makineleri Zemin Alanı | Toplam Alan Tasarrufu | |

| Chase Yükleyici ile | 197,3 m² | 148,5 m² | 48,8 m² |

| Chase Loade olmadan | 172,2 m² | 142,8 m² | 27,4 m² |

Aynı ayak pedalı paylaşıldığı için, iki makine ayrı ayrı yerleştirildiğinde ara kanal (en az 2×10 metre) 2×10=20m2 tesis işgal alanından tasarruf sağlanabilir.

Çizim

İncelemeler

Henüz yorum yapılmadı.