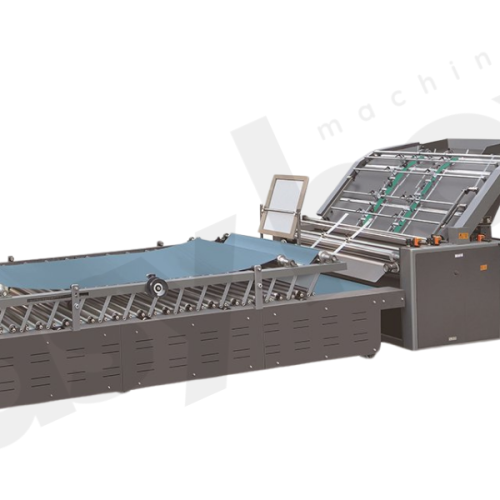

MHK 1050CE Otomatik Kalıp Kesme Makinesi Soyma Özellikli

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

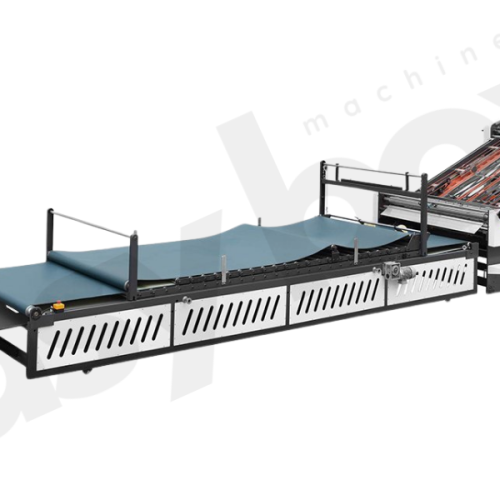

MHK 1050CE Otomatik Kalıp Kesme Makinesinin Sıyırma Özelliğine Giriş

MHK 1050CE Otomatik Kalıp Kesme Makinesi ve Soyma, paketleme ve baskı endüstrilerinde verimliliği ve hassasiyeti artırmak için tasarlanmış gelişmiş bir çözümdür. Bu son teknoloji makine, kalıp kesme ve soyma işlevlerini birleştirerek yüksek kaliteli çıktı ve akıcı üretim süreçleri sağlar.

Temel Özellikler

Yüksek Hassasiyet ve Doğruluk

MHK 1050CE milimetrelik mükemmellikte kalıp kesimi sunar ve bu da onu ayrıntılı ve kesin özellikler gerektiren uygulamalar için ideal hale getirir. Bu yüksek hassasiyet seviyesi, malzeme israfını azaltır ve yüksek üretim standartlarını korumak için olmazsa olmaz olan üstün ürün kalitesini garanti eder.

Entegre Soyma Fonksiyonu

MHK 1050CE'nin öne çıkan özelliklerinden biri entegre soyma işlevidir. Bu sistem, bitmiş üründen atık malzemeyi otomatik olarak kaldırarak temiz ve hassas kenarlar sağlar. Soyma işlevi manuel işçiliği azaltır ve üretim sürecini hızlandırır, bu da önemli işçilik maliyeti tasarruflarına yol açar.

Yüksek Hızlı Performans

Yüksek hızlı operasyonlar için tasarlanan MHK 1050CE, üretkenliği önemli ölçüde artırır. Sağlam yapısı ve gelişmiş teknolojisi, büyük ölçekli üretimi verimli bir şekilde yönetmesini, doğruluktan ödün vermeden sıkı teslim tarihlerine uymasını sağlar.

Faydalar

- Gelişmiş Verimlilik: Yüksek hızlı operasyonlar ve entegre sıyırma fonksiyonunun birleşimi iş akışını hızlandırır, duruş süresini ve işçilik maliyetlerini azaltır.

- Kullanıcı Dostu Arayüz: Sezgisel dokunmatik ekran, kolay kurulum ve gerçek zamanlı izleme olanağı sunarak operatörler için öğrenme eğrisini en aza indirir ve sorunsuz bir çalışma sağlar.

- Güvenlik Özellikleri: Acil durdurma düğmeleri ve koruyucu muhafazalarla donatılan makine, en yüksek endüstri standartlarına bağlı kalarak güvenli bir çalışma ortamı sağlar.

Uygulamalar

MHK 1050CE, paketleme, etiketler, tabelalar ve özel baskı malzemeleri dahil olmak üzere çeşitli uygulamalar için mükemmeldir. Çok yönlülüğü, hassasiyeti ve entegre soyma işlevi, üretim süreçlerini optimize etmek ve yüksek hacimli talepleri karşılamak isteyen işletmeler için onu değerli bir varlık haline getirir.

Çözüm

MHK 1050CE Otomatik Kalıp Kesme Makinesi, hassasiyet, hız ve verimliliğin birleşimiyle sektörde yeni bir standart belirliyor. Modern üretimin taleplerini karşılamak üzere tasarlanan bu makine, işletmelerin yüksek kalite ve güvenlik standartlarını korurken üretkenliğini artırmasına yardımcı oluyor.

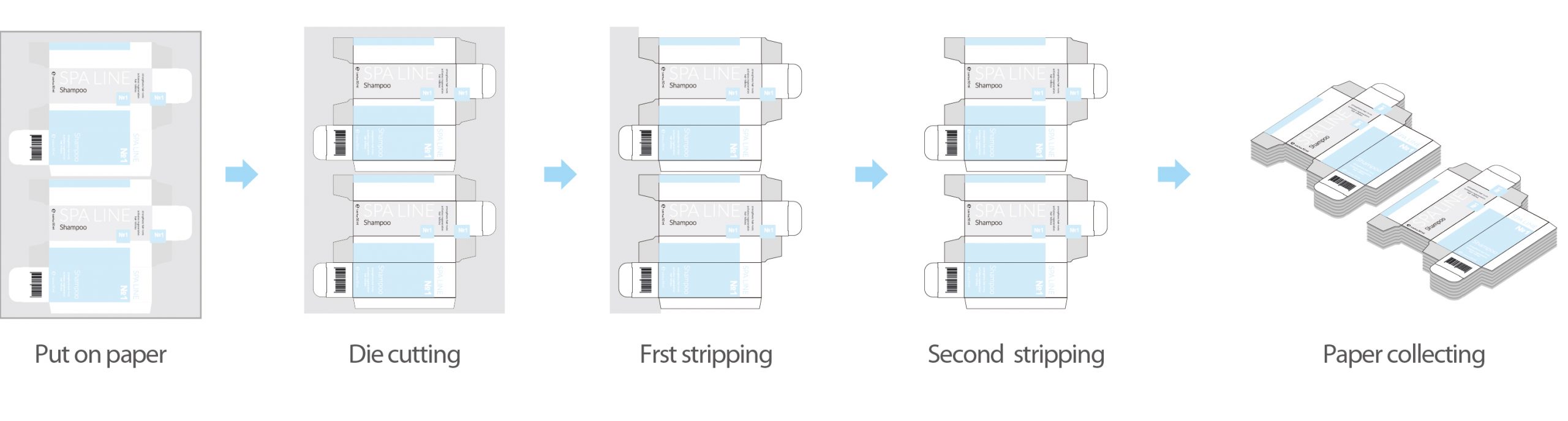

Süreç Akışı

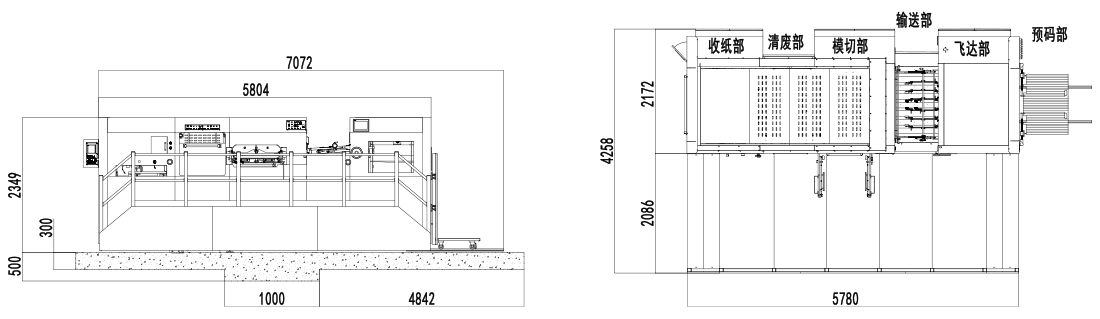

Çizim

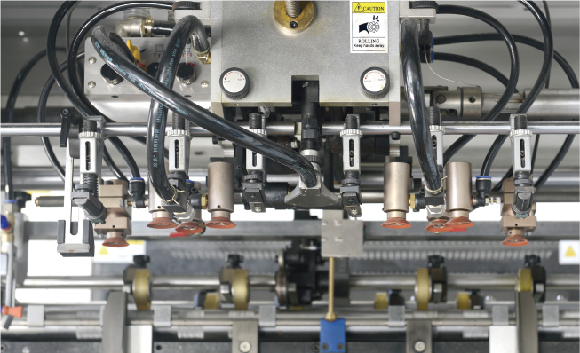

Kısmi Giriş

Besleyici ünitesi

Farklı türdeki malzemeleri işlemek için açı ayarlamalı dört alma ve dört ileri emme kafası.

Beslenme masası

Üretim esnasında levhanın ön tarafa doğru konumlandırılmasını elle ayarlamak için senkronizasyon cihazı, Levha tutma cihazı (levhaları ön tarafa doğru yönlendirir).

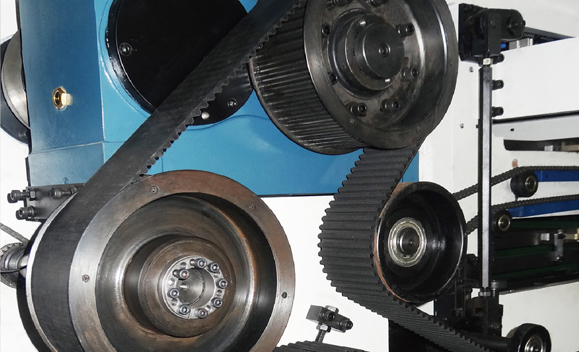

Tork sınırlayıcı

Tayvan'ın yüksek hassasiyetli aralıklı segmentasyonu, uzun süreli kullanımda yüksek konumsal hassasiyet sağlar.

Tayvan tork sınırlayıcı, hassas sınır koruma performansıyla insan ve makine güvenliğini garanti altına almak için yapay çalışma kazalarını doğru bir şekilde koruyabilir.

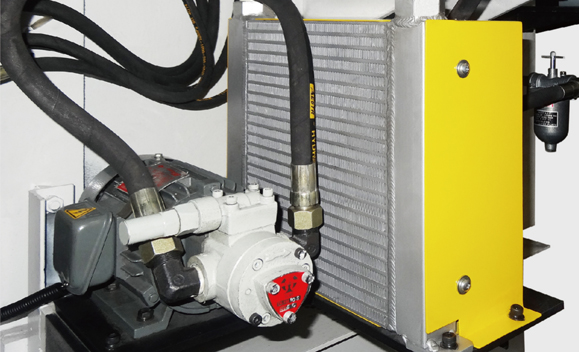

Ana motor yağlama sistemi

Ana motorun uzun süre yüksek hızda yağlanmasını sağlamak için Tayvan yapımı otomatik yağ pompası soğutma sirkülasyon sistemi.

Yağ basınç göstergesi ve yağ basınç alarm cihazı ile donatılmıştır.

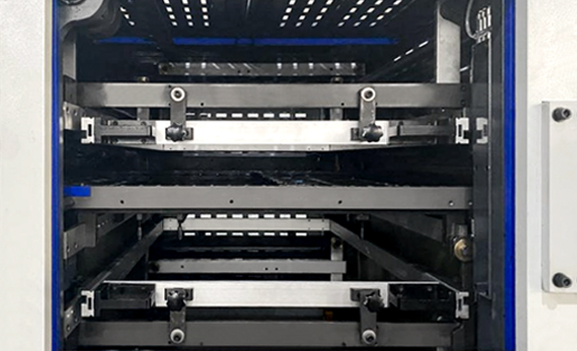

Soyma ünitesi

Merkez hattı sistemini benimseyin, Üst ve alt soyma aleti montaj çerçevesi iş kurulumu ve hazır hale getirmek için dışarı çekilebilir.

Tutma kenarı atık giderme cihazı

Tutucu kenar sıyırma ve çıkarma sistemi, tutucu kenar atıklarını yanlara doğru tahrik tarafına çıkarmak için konveyör bant ile çalışır.

Teslimat ünitesi

Kesintisiz perdeli otomatik teslimat. Bu perde, yığın değişimi sırasında gelen sayfaları yakalamak için teslimata hareket eder. Kağıt toplama için iki üfleyici, ince ve kalın kağıtların düzgün bir şekilde toplanmasını sağlayabilir.

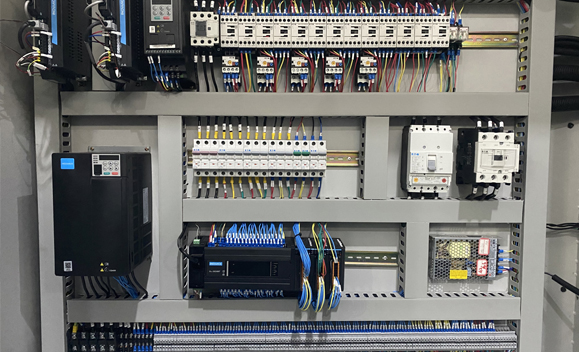

Elektrik ünitesi

Daha iyi performans ve zamanında ve yerel satış sonrası servis ve bakım için dünyaca ünlü markaların (MOELLER\OMRON) elektrik bileşenlerini benimser.

Almanya vakum pompası

Almanya Becker yağsız üfleme ve vakum pompası.

Otomatik yağlama sistemi

Tahrik edilen parçaların daha iyi çalışmasını sağlamak için yoğunlaştırılmış otomatik yağlama sistemini benimseyin.

Ek bilgi

| Örnek | MHK-1050CE |

|---|---|

| Maksimum Sayfa Boyutu | 1050×750mm |

| Minimum Sayfa Boyutu | 400×360mm |

| Maksimum Kesim Boyutu | 1040×720mm |

| Minimum Gripper Marjı | 9-17mm |

| İç Kovalamaca Boyutu | 1140×755mm |

| Stok Aralığı | Kağıt: 80 ila 2000g/m2, 0,1~2mm, oluklu mukavva: 4mm'ye kadar |

| Kalıp Kesim Doğruluğu | ≤±0,075 mm |

| Max.kalıp Kesme Kuvveti | 300T |

| Maksimum Çalışma Hızı | 7500s/saat |

| Maksimum besleyici yığın yüksekliği | 1600mm(Ahşap paletli) |

| Maksimum teslimat yığın yüksekliği | 1400mm(Ahşap paletli) |

| Makine Boyutları | 7072×4257×2349mm (U×G×Y) (U: kağıtla hazırlanmış ray dahil, G: platform dahil) |

| Makinenin Net Ağırlığı | 17T |

| Ana motor gücü | 11kw |

| Tam Yük Watt Değeri | 16.9kw |

| Hava İhtiyacı | Basınç: 0,6~0,7Mpa, Debi: ≥0,37m3/dak |

| Açıklama | MHK-1050 S9000 serisinin maksimum hızı 9000s/h olup, diğer parametreler MHK-1050 serisi ile aynıdır. |

İncelemeler

Henüz yorum yapılmadı.