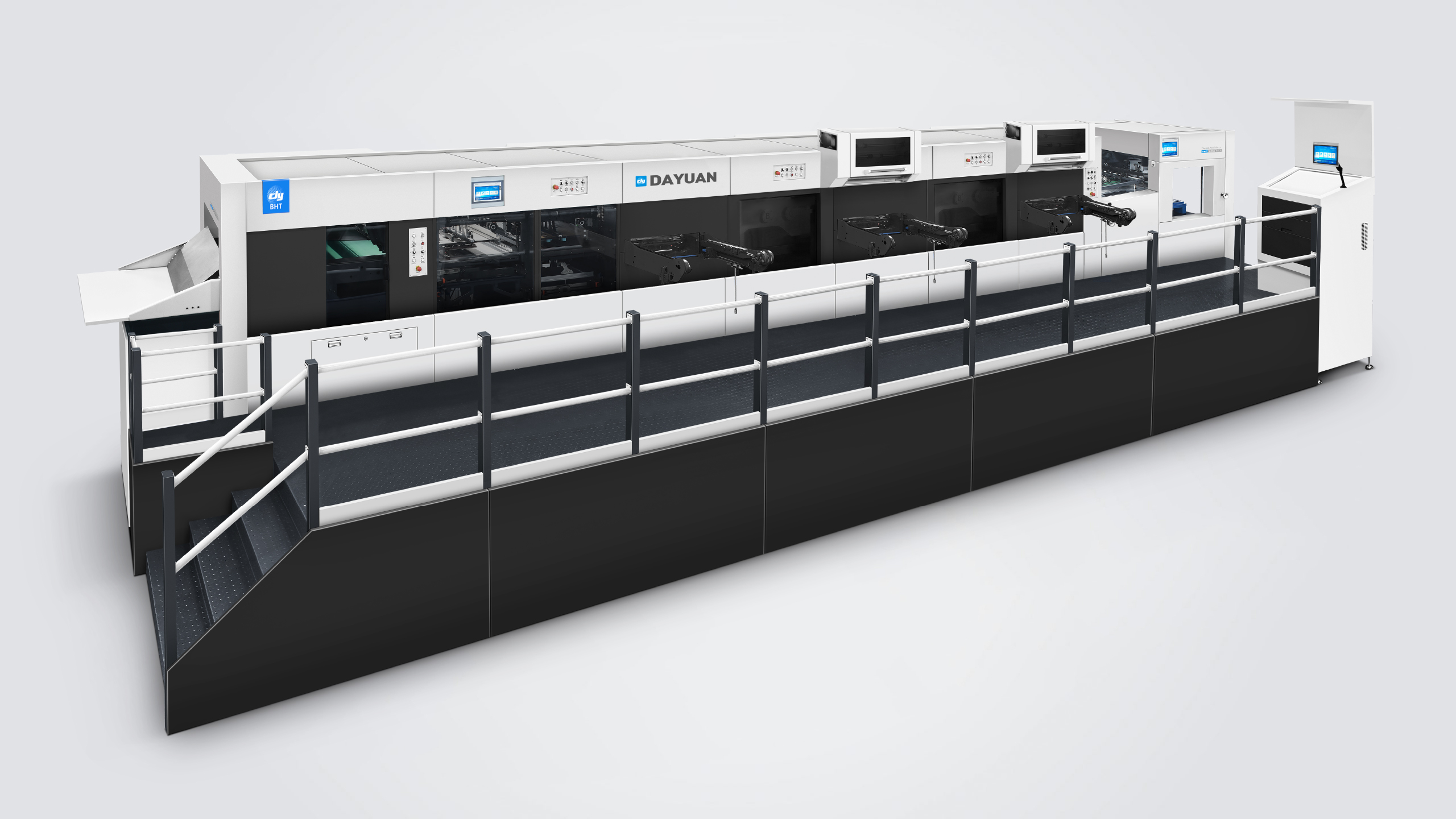

BHT 3S1060TTMSCE TRIOPRESS Otomatik Yüksek Hızlı Çift Sıcak Damgalama ve Kalıp Kesme Makinesi, Soyma ve Kesme

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

BHT 3S1060TTMSCE TRIOPRESS Otomatik Yüksek Hızlı Çift Sıcak Damgalama ve Kalıp Kesme Makinesi, Soyma ve Kesme: Üstün Verimlilik ve Hassasiyet

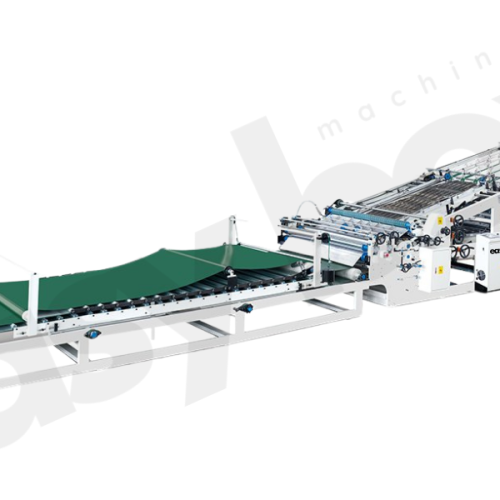

BHT 3S1060TTMSCE TRIOPRESS, soyma ve kesme yetenekleriyle donatılmış, çift sıcak damgalama ve kalıp kesme için tasarlanmış gelişmiş, yüksek hızlı bir makinedir. Bu son teknoloji ekipman, yüksek kaliteli son işlem süreçleri talep eden endüstriler için ideal hale getiren olağanüstü hassasiyet, verimlilik ve çok yönlülük sunar.

Temel Özellikler ve Avantajlar

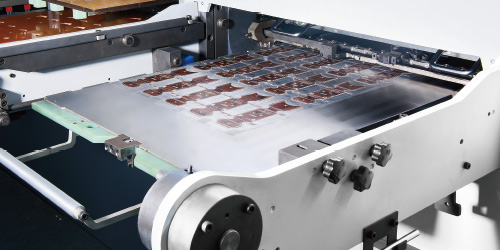

Çift Sıcak Damgalama

BHT 3S1060TTMSCE, çeşitli malzemeler üzerinde karmaşık ve yüksek kaliteli folyo tasarımları sağlayan çift sıcak damgalama sistemine sahiptir. Bu çift damgalama yeteneği, ürünlerin estetik çekiciliğini artırarak onu lüks ambalajlar, üst düzey etiketler ve dekoratif ürünler için mükemmel hale getirir.

Hassas Kalıp Kesimi

Gelişmiş kalıp kesme mekanizmasıyla bu makine her seferinde temiz ve doğru kesimler sağlar. Hassas kalıp kesme özelliği, baskı, paketleme ve dekorasyon endüstrileri gibi ayrıntılı ve kusursuz yüzeyler gerektiren uygulamalar için çok önemlidir.

Yüksek Hızlı Operasyon

TRIOPRESS BHT 3S1060TTMSCE, yüksek hızlı üretim için tasarlanmıştır, verimi önemli ölçüde artırır ve teslim sürelerini azaltır. Bu yüksek hız yeteneği, büyük ölçekli üretim ortamları için önemlidir ve bitmiş ürünlerin verimli ve zamanında teslimatını sağlar.

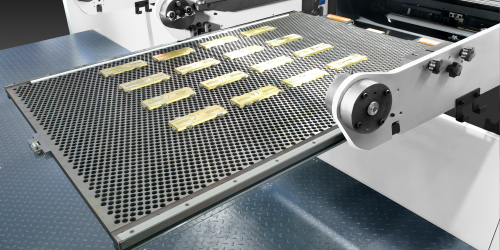

Soyma ve Kesme Yetenekleri

Entegre soyma ve kesme özellikleri, atıkları otomatik olarak kaldırarak ve bitmiş ürünleri hurdadan ayırarak üretim sürecini kolaylaştırır. Bu otomasyon manuel işçiliği azaltır, verimliliği artırır ve daha temiz bir üretim ortamı sağlar.

Sağlam Yapı

Yüksek kaliteli malzemelerle üretilen BHT 3S1060TTMSCE, dayanıklılık ve sağlamlık için tasarlanmıştır. Ağır hizmet tipi yapısı, sürekli çalışma sırasında güvenilir performans sağlar ve onu yüksek hacimli üretim görevleri için uygun hale getirir.

Kullanıcı Dostu Arayüz

Makine, operatörlerin parametreleri kolayca ayarlayıp ayarlamasına, üretim sürecini izlemesine ve sorunları gidermesine olanak tanıyan sezgisel bir kullanıcı arayüzüne sahiptir. Bu kullanıcı dostu tasarım, üretkenliği artırır ve yeni operatörler için öğrenme eğrisini azaltır.

Güvenlik Özellikleri

Güvenlik, BHT 3S1060TTMSCE tasarımında en önemli önceliktir. Makine, acil durdurma düğmeleri, güvenlik korumaları ve potansiyel tehlikeleri algılayıp bunlara yanıt veren sensörler dahil olmak üzere birden fazla güvenlik mekanizmasıyla donatılmıştır ve tüm kullanıcılar için güvenli bir çalışma sağlar.

Çok Yönlü Uygulamalar

BHT 3S1060TTMSCE çok yönlüdür ve kağıt, karton, plastik levhalar ve daha fazlası dahil olmak üzere çok çeşitli malzemeleri işleyebilir. Uyarlanabilirliği onu aşağıdakiler dahil olmak üzere çeşitli endüstriler için mükemmel bir seçim haline getirir:

- Baskı: Baskılı materyaller için yüksek kalitede damgalama ve kesim hizmeti sunuyoruz.

- Ambalajlama: Ambalaj malzemeleri için hassas kalıp kesimi ve folyo damgalama hizmeti sunuyoruz.

- Etiketler ve Etiketler: Etiketler ve taglar için detaylı ve ilgi çekici tasarımlar oluşturmak.

- Dekoratif Uygulamalar: Dekoratif ürünleri karmaşık kesimler ve folyo detaylarıyla zenginleştirin.

Gelişmiş Üretkenlik

Yüksek hızlı çalışma, çift sıcak damgalama, kalıp kesme, soyma ve kesme işlevlerinin tek bir makinede birleştirilmesi genel üretkenliği artırır. Bu kombinasyon, duruş süresini azaltır, manuel müdahaleyi en aza indirir ve tüm üretim çalışmalarında tutarlı kaliteyi garanti eder.

Teknolojik Gelişmeler

BHT 3S1060TTMSCE TRIOPRESS, servo hassas kontrol sistemleri ve otomatik işlevler gibi gelişmiş teknolojik özellikleriyle öne çıkıyor. Bu yenilikler üretim sürecini basitleştiriyor, duruş süresini azaltıyor ve verimliliği artırıyor, bu da bu makineyi modern üretim operasyonları için değerli bir varlık haline getiriyor.

Çözüm

BHT 3S1060TTMSCE TRIOPRESS Otomatik Yüksek Hızlı Çift Sıcak Damgalama ve Kalıp Kesme Makinesi, Soyma ve Kesme ile üstün bir hassasiyet, hız ve gelişmiş otomasyon kombinasyonu sunar. Sağlam yapısı, kullanıcı dostu arayüzü ve çok yönlü uygulamaları, bitirme süreçlerini geliştirmek isteyen işletmeler için mükemmel bir yatırım olmasını sağlar. İster baskı, ister paketleme veya dekoratif uygulamalar için olsun, BHT 3S1060TTMSCE olağanüstü performans ve güvenilirlik sunarak günümüzün endüstriyel ortamlarının yüksek taleplerini karşılar.

Kısmi Giriş

Besleyici

90g/m'den başlayan geniş yelpazedeki stokları hassas ve tutarlı bir şekilde besleyen ileri teknik platforma dayalı besleyici2 1000g/m'ye kadar ince kağıt2 karton ve mikro flüt oluklu mukavva.

Çift sayfa dedektörü

Kağıda temas etmeden ultrasonik çift sayfa dedektörü, dolayısıyla çizilmez, güvenilir ve hızlı kurulum.

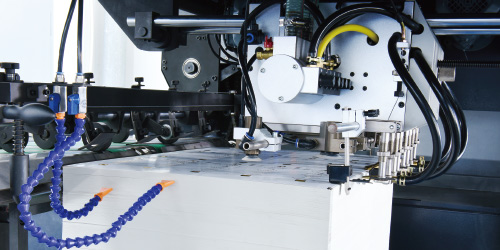

Tutma çubuğu

Son teknoloji keskin uçlu tutucu çubuklar, büyük hareket açılı eksantrik sonsuz dişli tahrik sisteminin benzersiz tasarımı sayesinde son derece sorunsuz çalışır.

Sıcak damgalama bölümü

600 tona kadar maksimum damgalama basıncı, şarap kutuları ve sigara kutuları gibi büyük formatlı baskı malzemelerinde daha iyi 3D ve mükemmel efekt elde etmeyi mümkün kılar.

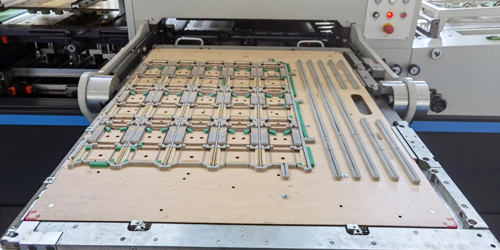

Tabak ayarı

5mm sertleştirilmiş kesme plakası veya üstte 4+1mm sandviç plaka. Hızlı kurulum ve kolay hazırlama için +/-0,9mm mikro ayarlı 15mm hassas sentetik destek plakası.

Kalıp hızlı kilitleme cihazı

Hazırlanma süresini kısaltmak için merkez hat sistemini ve hızlı kilitleme cihazını benimseyin.

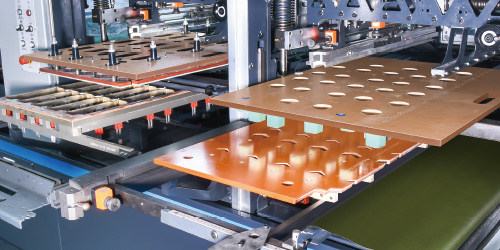

Gelişmiş takım kilitleme

Gelişmiş hızlı takım kurulum sistemi, hem sıyırma hem de kesme istasyonlarında hızlı iş değişimini ve dolayısıyla yüksek verimliliği garanti eder.

Tam sayfa teslimat

Son teslimat şeklini seçerek kolay üretim planlamasını garanti altına almak için tam sayfa teslimat seçeneği.

Otomatik ayırma kağıdı ek parçası

Kesme istasyonunda elektronik pozisyon sensörü ile birleştirilmiş otomatik ayırma kağıdı yerleştirici.

Kesintisiz örnekleme

Örnekleme Fonksiyonu, tek bir tuşla anında bir örnek kağıdını çıkarmak için kullanılabilir, kullanımı kolaydır.

Almanya vakum pompası

Almanya Becker yağsız üfleme ve vakum pompası.

Otomatik yağlama sistemi

Tahrik edilen parçaların daha iyi çalışmasını sağlamak için yoğunlaştırılmış otomatik yağlama sistemini benimseyin.

Ek bilgi

| Örnek | BHT-3S1060TTMSCE |

|---|---|

| İşlev | 1. sıcak damgalama + sıcak damgalama + kalıp kesme + sıyırma + boşaltma |

| Maksimum Sayfa Boyutu | 1060×760mm |

| Minimum Sayfa Boyutu | 400×350mm |

| Maksimum Kesim Boyutu | 1060×745mm |

| Maksimum Damgalama Boyutu | 1060×740mm |

| Minimum Gripper Marjı | 9~17mm |

| İç Kovalamaca Boyutu | 1080×770mm |

| Stok Aralığı | Kağıt: 80 ila 2000g/m2, 0.1~2mm, |

| Kalıp Kesim Doğruluğu | ≤±0,075 mm |

| Genel Damgalama Doğruluğu | ≤±0,075 mm |

| Hologram Konumlandırma Damgalama Doğruluğu | ≤±0,075 mm |

| Max.kalıp Kesme Kuvveti | Pres1: 600T, Pres2: 600T, Pres3: 300T |

| Maksimum Çalışma Hızı | 6200s/saat |

| Besleyici-Normal Modda Maksimum Yığın Yüksekliği | 1800mm |

| Besleyicide Maksimum Yığın Yüksekliği - Kesintisiz Mod | 1520mm |

| Teslimatta Maksimum Yığın Yüksekliği | 1580mm |

| Max.gold Folyo Çapı | Φ250mm Boyuna; Φ200mm Enine |

| Elektrikle ısıtılan sistem | 20 Isıtma bölgesi, 40~180℃Ayarlanabilir |

| Folyo Genişliği | 20~1060mm |

| Press1 Folyo İleri Şaftları | 3 Boyuna + 2 Enine (Opsiyonel) |

| Press2 Folyo İleri Şaftları | 3 Boyuna + 2 Enine (Opsiyonel) |

| Basın3 | kalıp kesme+sıyırma |

| Makine Boyutları | 14078×5857×2657mm (U×G×Y) |

| Makinenin Net Ağırlığı | 52000kg |

| Tam Yük Watt Değeri | 145 kW |

| Hava İhtiyacı | Basınç: 0,6~0,7Mpa, Debi: ≥1m3/dak |

İncelemeler

Henüz yorum yapılmadı.