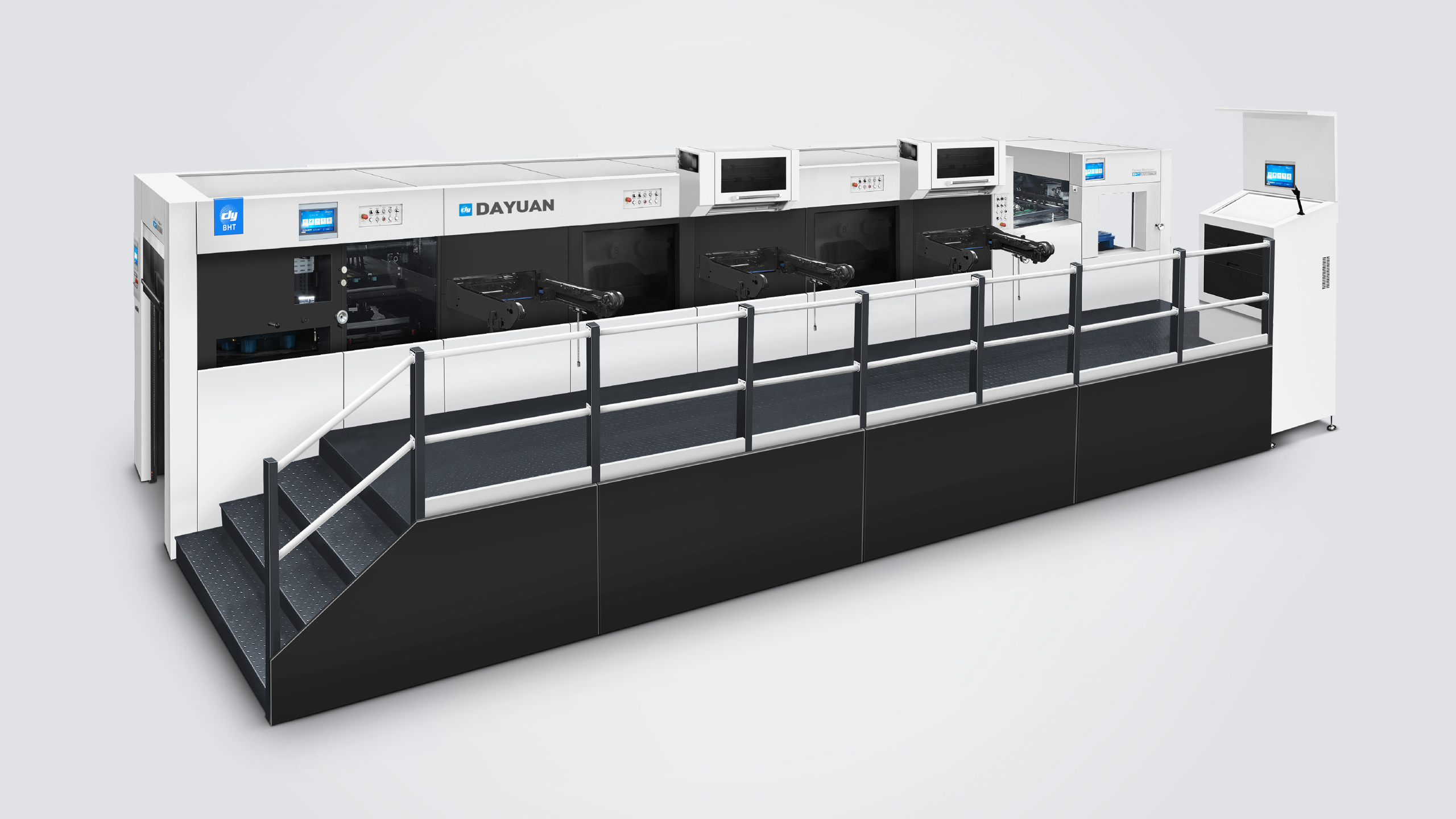

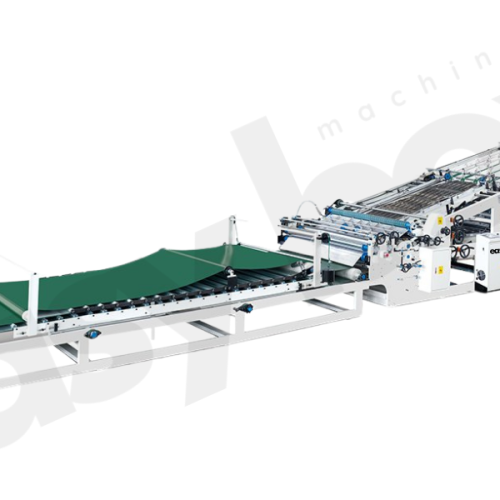

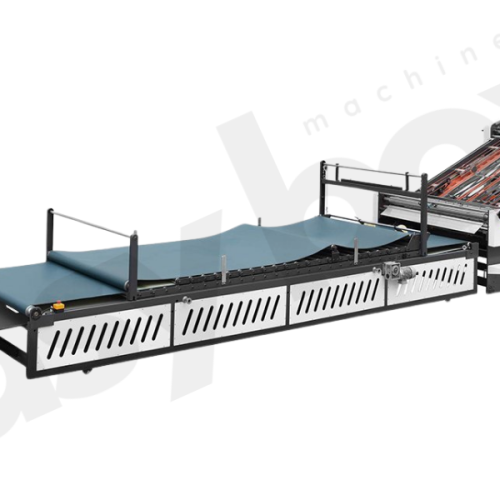

BHT 3S1060TTMC TRIOPRESS Automatic High Speed Duoble Hot Stamping & Die Cutting Machine with Stripping & Heating System

Bu ürünü beğendiniz mi? Hemen favorilere ekleyin ve ürünü takip edin.

(+86) 158 9968 3398 WhatsApp Sohbeti

Açıklama

BHT 3S1060TTMC TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine with Stripping & Heating System: Precision and Efficiency for Modern Manufacturing

The BHT 3S1060TTMC TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine is a state-of-the-art machine designed to meet the high demands of modern manufacturing. Equipped with advanced stripping and heating systems, this machine ensures exceptional precision, speed, and reliability, making it an ideal choice for industries requiring high-quality finishing processes.

Key Features and Benefits

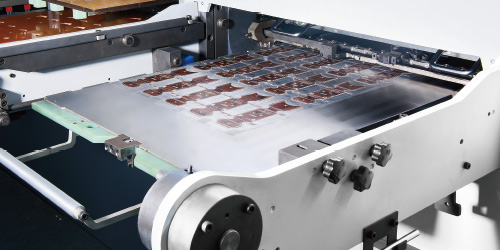

Double Hot Stamping System

The BHT 3S1060TTMC features a double hot stamping system that allows for intricate and high-quality foil designs on various materials. This dual stamping capability enhances the visual appeal of products, making it perfect for luxury packaging, high-end labels, and decorative items.

Precision Die Cutting

The machine offers advanced die-cutting capabilities, ensuring clean and accurate cuts every time. This precision is essential for applications that require detailed and flawless finishes, such as printing, packaging, and decorative industries.

High-Speed Operation

Designed for efficiency, the BHT 3S1060TTMC delivers high-speed cutting and stamping performance, significantly increasing production throughput. This high-speed capability is crucial for large-scale production environments, ensuring timely completion of substantial orders without compromising on quality.

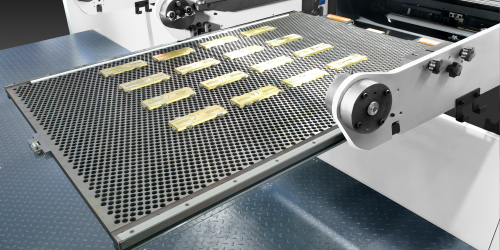

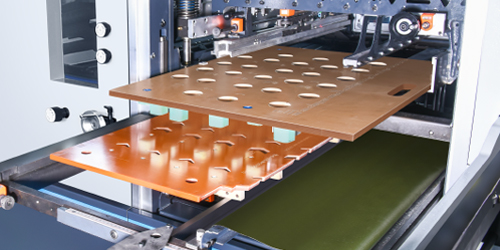

Advanced Stripping System

The integrated stripping system automatically removes waste material, streamlining the production process and reducing the need for manual intervention. This feature increases efficiency and ensures a cleaner production environment.

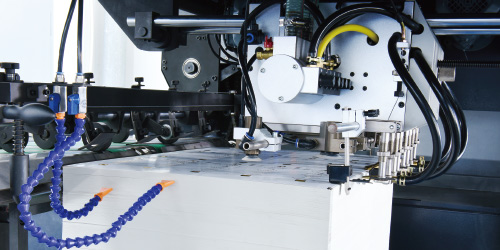

Efficient Heating System

The advanced heating system ensures consistent and precise temperature control, which is critical for high-quality hot stamping. This system enhances the overall reliability and performance of the machine, ensuring uniform results across all production runs.

Robust Construction

Built with high-quality materials, the BHT 3S1060TTMC is designed for durability and stability. Its heavy-duty construction ensures reliable performance under continuous operation, making it suitable for high-volume production tasks.

Kullanıcı Dostu Arayüz

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Safety Features

Safety is a top priority with the BHT 3S1060TTMC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Versatile Applications

The BHT 3S1060TTMC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Printing: Delivering high-quality stamping and cutting for printed materials.

- Packaging: Providing precise die-cutting and foil stamping for packaging materials.

- Labels and Tags: Creating detailed and attractive designs for labels and tags.

- Decorative Applications: Enhancing decorative items with intricate cuts and foil accents.

Enhanced Productivity

The integration of high-speed operation, double hot stamping, die cutting, stripping, and heating functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Technological Advancements

The BHT 3S1060TTMC TRIOPRESS stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Çözüm

The BHT 3S1060TTMC TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine with Stripping & Heating System offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the BHT 3S1060TTMC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Kısmi Giriş

Besleyici

90g/m'den başlayan geniş yelpazedeki stokları hassas ve tutarlı bir şekilde besleyen ileri teknik platforma dayalı besleyici2 1000g/m'ye kadar ince kağıt2 karton ve mikro flüt oluklu mukavva.

Çift sayfa dedektörü

Kağıda temas etmeden ultrasonik çift sayfa dedektörü, dolayısıyla çizilmez, güvenilir ve hızlı kurulum.

Tutma çubuğu

Son teknoloji keskin uçlu tutucu çubuklar, büyük hareket açılı eksantrik sonsuz dişli tahrik sisteminin benzersiz tasarımı sayesinde son derece sorunsuz çalışır.

Hot stamping section

Max stamping pressure up to 600 tons, which makes it able to achieve better 3D and exquisite effect on large format printing materials such as wine boxes and cigarette boxes.

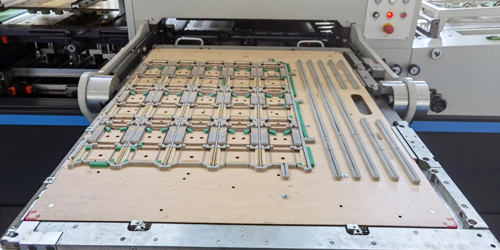

Tabak ayarı

5mm sertleştirilmiş kesme plakası veya üstte 4+1mm sandviç plaka. Hızlı kurulum ve kolay hazırlama için +/-0,9mm mikro ayarlı 15mm hassas sentetik destek plakası.

Kalıp hızlı kilitleme cihazı

Hazırlanma süresini kısaltmak için merkez hat sistemini ve hızlı kilitleme cihazını benimseyin.

Gelişmiş takım kilitleme

Gelişmiş hızlı takım kurulum sistemi, hem sıyırma hem de kesme istasyonlarında hızlı iş değişimini ve dolayısıyla yüksek verimliliği garanti eder.

Almanya vakum pompası

Almanya Becker yağsız üfleme ve vakum pompası.

Otomatik yağlama sistemi

Tahrik edilen parçaların daha iyi çalışmasını sağlamak için yoğunlaştırılmış otomatik yağlama sistemini benimseyin.

Ek bilgi

| Örnek | BHT-3S1060TTMC |

|---|---|

| İşlev | 1. hot stamping+hot stamping+die cutting+stripping |

| Stok Aralığı | Kağıt: 80 ila 2000g/m2, 0,1~2mm, oluklu mukavva: 4mm'ye kadar |

| Maksimum Sayfa Boyutu | 1060×760mm |

| Minimum Sayfa Boyutu | 400×350mm |

| İç Kovalamaca Boyutu | 1080×770mm |

| Maksimum Kesim Boyutu | 1060×745mm |

| Maksimum Damgalama Boyutu | 1060×740mm |

| Minimum Gripper Marjı | 9~17mm |

| Çift Kesimlerin Minimum Genişliği | 5mm |

| Kalıp Kesim Doğruluğu | ≤±0,075 mm |

| Stamping Accuracy | ≤±0,075 mm |

| Max.kalıp Kesme Kuvveti | 600ton + 600ton + 300ton |

| Maksimum Çalışma Hızı | 6200s/h |

| Besleyici-Normal Modda Maksimum Yığın Yüksekliği | 1800mm |

| Besleyicide Maksimum Yığın Yüksekliği - Kesintisiz Mod | 1520mm |

| Teslimatta Maksimum Yığın Yüksekliği | 1580mm |

| Max.gold Foil Diameter | Φ250mm Longitudinal, Φ200mm Transversal |

| Elektrikle ısıtılan sistem | 20 Isıtma bölgesi, 40~180℃ Ayarlanabilir |

| Foil Width | 20~1060mm |

| Press1 Folyo İleri Şaftları | 3 Longitudinal + 2 Transversal (Optional) |

| Press2 Folyo İleri Şaftları | 3 Longitudinal + 2 Transversal (Optional) |

| Press3 | kalıp kesme+sıyırma |

| Makine Boyutları (U×G×Y) | 11700×4708×2900mm |

| Makine Boyutları (Kalıp Ön Yükleyici Dahil) (U×G×Y) | 11700×5608×2900mm |

| Makinenin Net Ağırlığı | 61000kg |

| Tam Yük Watt Değeri | 129KW |

| Hava İhtiyacı | Basınç: 0,6~0,7Mpa, Debi: ≥1m3/dak |

İncelemeler

Henüz yorum yapılmadı.