BHT 2S1060TRC DUOPRESS Automatisk höghastighetsfoliepressnings- och stansmaskin med värmesystem

(+86) 158 9968 3398 WhatsApp Chat

Product Description

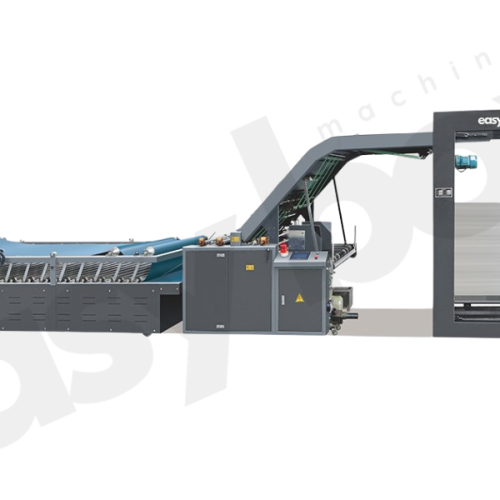

BHT 2S1060TRC DUOPRESS Automatic High Speed Foil Stamping and Die Cutting Machine with Heating System: Advanced Precision for High-Demand Industries

The BHT 2S1060TRC DUOPRESS Automatic High Speed Foil Stamping and Die Cutting Machine with Heating System is an innovative piece of equipment designed to meet the exacting needs of modern manufacturing. By combining high-speed foil stamping and precision die cutting with an integrated heating system, this machine offers unparalleled efficiency, accuracy, and reliability.

Nyckelfunktioner och fördelar

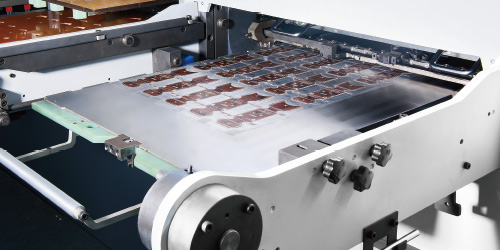

High-Speed Foil Stamping System

The BHT 2S1060TRC is equipped with a high-speed foil stamping system that delivers intricate and high-quality foil designs on a variety of materials. This feature enhances the aesthetic appeal of products, making it perfect for luxury packaging, high-end labels, and decorative items.

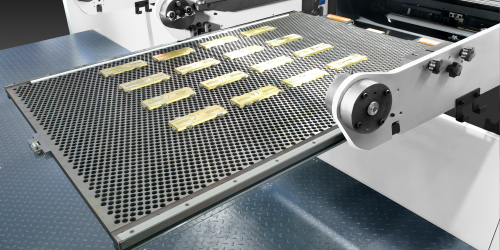

Precisionsstansning

With its advanced die-cutting capabilities, the BHT 2S1060TRC ensures clean and precise cuts every time. This precision is crucial for applications requiring detailed and flawless finishes, such as in the printing, packaging, and decorative industries.

Integrerat värmesystem

The integrated heating system provides consistent and precise temperature control, which is essential for high-quality foil stamping. This feature enhances the machine’s overall reliability and performance, ensuring uniform results across all production runs.

Höghastighetsdrift

The BHT 2S1060TRC is designed for high-speed operation, significantly increasing production throughput. This capability is vital for large-scale production environments, ensuring timely completion of substantial orders without compromising on quality.

Robust Construction

Constructed from high-quality materials, the BHT 2S1060TRC is built for durability and stability. Its heavy-duty construction ensures reliable performance under continuous operation, making it suitable for high-volume production tasks.

Användarvänligt gränssnitt

The machine features an intuitive user interface that allows operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Säkerhetsanordningar

Safety is a top priority with the BHT 2S1060TRC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Mångsidiga applikationer

The BHT 2S1060TRC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Utskrift: Levererar högkvalitativ stämpling och skärning för tryckt material.

- Förpackning: Tillhandahåller exakt stansning och foliestämpling för förpackningsmaterial.

- Etiketter och taggar: Skapa detaljerade och attraktiva mönster för etiketter och etiketter.

- Dekorativa applikationer: Förbättra dekorativa föremål med intrikata snitt och folieaccenter.

Förbättrad produktivitet

The integration of high-speed operation, foil stamping, die cutting, and heating functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Tekniska framsteg

The BHT 2S1060TRC DUOPRESS stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Slutsats

The BHT 2S1060TRC DUOPRESS Automatic High Speed Foil Stamping and Die Cutting Machine with Heating System offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the BHT 2S1060TRC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Delvis introduktion

Matare

Matare baserad på avancerad teknisk plattform som matar exakt och konsekvent av brett sortiment från 90g/m2 tunt papper till 1000g/m2 kartong samt micro flute wellpapp.

Dubbelplåtsdetektor

Ultraljudsdetektor med dubbla ark utan att röra papperet, därför repfri, pålitlig och snabb installation.

Gripstång

Gripstänger tillverkade av den senaste tekniken som löper extremt smidigt, tack vare den unika designen av excentrisk snäckväxel med stor rörelsevinkel.

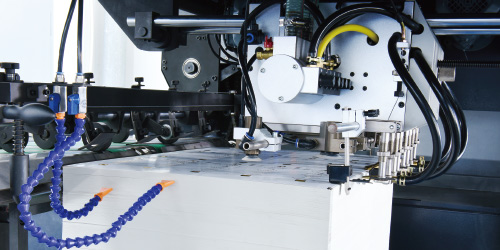

Varmstämplingssektion

Max stamping pressure up to 600 tons, which makes it able to achieve better 3D and exquisite effect on large format printing materials such as wine boxes and cigarette boxes.

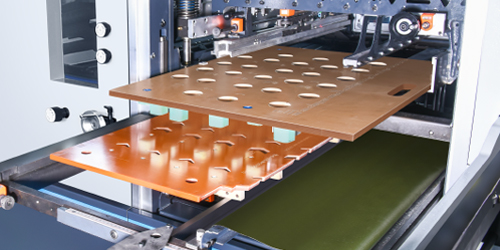

Tallrikinställning

5 mm härdad skärplatta eller 4+1 mm sandwichplatta ovanpå 15 mm precision syntetisk stödplatta med +/-0,9 mm mikrojustering för snabb uppsättning och enkel att göra klar.

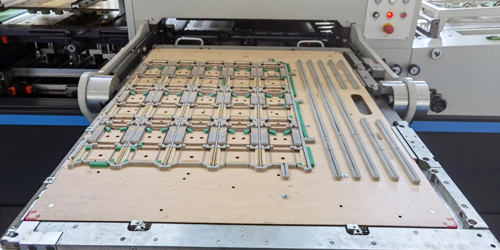

Formsnabblåsanordning

Använd mittlinjesystem och snabblåsningsanordning för att spara tid.

Advanced tooling lockup

Advanced quick tooling set up system ensures fast job change over and hence high productivity at both stripping and blanking stations.

Tyskland vakuumpump

Tyskland Becker oljefri fläkt och vakuumpump.

Automatiskt smörjsystem

Använd ett koncentrerat autosmörjsystem för att se till att de drivna delarna fungerar bättre.

Machine Parameters

| Modell | BHT-2S1060TRC |

|---|---|

| Fungera | 1. hot stamping+deep embossing |

| Lagersortiment | Papper: från 80 till 2000g/m2, 0,1~2mm, wellpapp: upp till 4mm |

| Maximal arkstorlek | 1060×760 mm |

| Minsta arkstorlek | 400×350 mm |

| Inner Chase Storlek | 1080×770 mm |

| Maximal skärstorlek | 1060×745 mm |

| Maximum Stamping Size | 1060×740mm |

| Minsta gripmarginal | 9~17mm |

| Minsta bredd på dubbla snitt | 5 mm |

| Skärprecision | ≤±0,075 mm |

| Stamping Accuracy | ≤±0,075 mm |

| Max. skärkraft | 600ton + 600ton |

| Max.arbetshastighet | 7200s/h |

| Maximum Pile Height at Feeder-Normal Mode | 1800 mm |

| Maximum Pile Height at Feeder-Non-stop Mode | 1520mm |

| Maximum Pile Height at Delivery | 1580mm |

| Max.guld Folie Diameter | Φ250mm Longitudinal, Φ200mm Transversal |

| Eluppvärmt system | 20 Heating zones, 40~180℃ Adjustable |

| Foliebredd | 20~1060mm |

| Press1 Foil Advance Shafts | 3 Longitudinal + 2 Transversal (Optional) |

| Press2 Foil Advance Shafts | Electric-heated system |

| Maskinmått (L×B×H) | 9683×4708×2900mm |

| Machine Dimensions (Including Die Preloader) (L×W×H) | 9683×5608×2900mm |

| Maskinens nettovikt | 46000kg |

| Full belastning Watt | 84KW |

| Luftkrav | Tryck: 0,6~0,7Mpa, flöde: ≥1m3/min |

Recensioner

Det finns inga recensioner än.