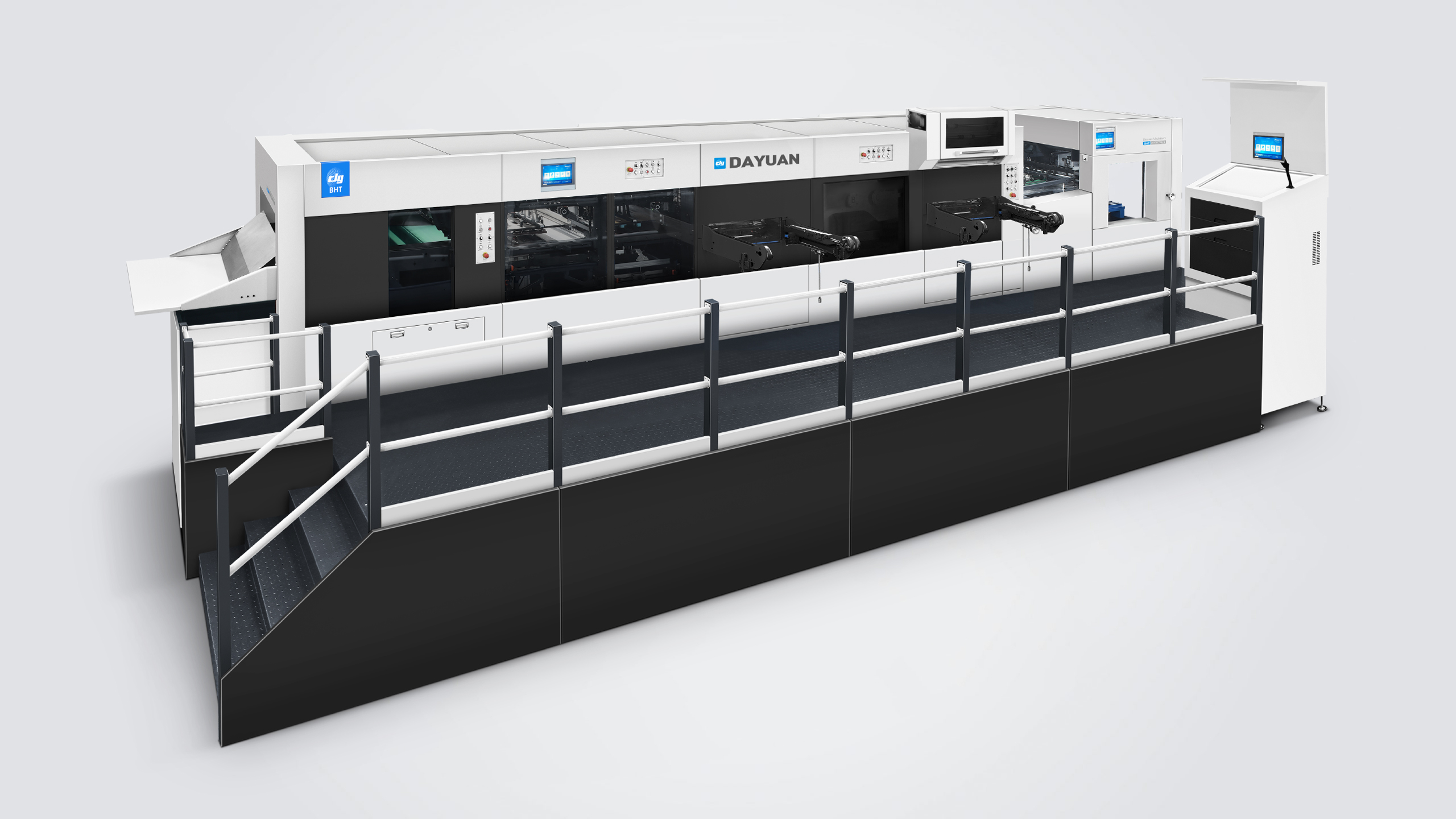

BHT 2S1060TMSCE DUOPRESS Автоматическая высокоскоростная машина для горячей штамповки и высечки с функцией зачистки и вырубки

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Чат WhatsApp

Product Description

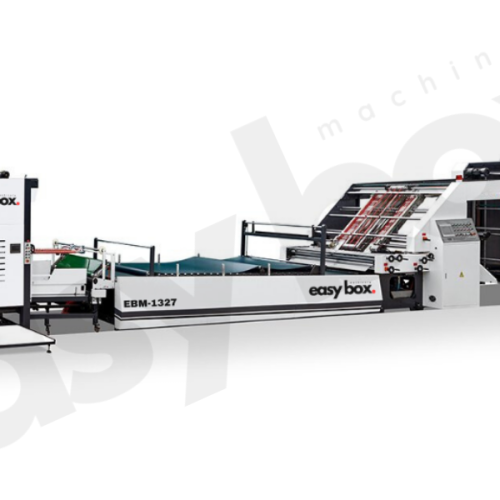

BHT 2S1060TMSCE DUOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Blanking: Precision and Efficiency in Modern Manufacturing

The BHT 2S1060TMSCE DUOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine is an advanced machine designed to meet the demanding needs of modern manufacturing. Equipped with integrated stripping and blanking systems, this machine offers exceptional precision, speed, and reliability, making it the ideal choice for industries requiring high-quality finishing processes.

Основные характеристики и преимущества

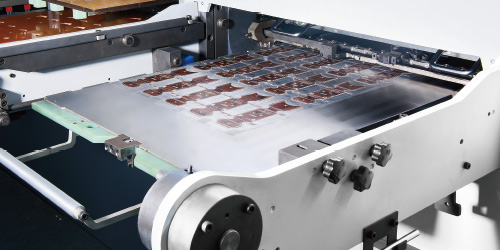

High-Speed Hot Stamping System

The BHT 2S1060TMSCE features a high-speed hot stamping system that allows for intricate and high-quality foil designs on various materials. This capability enhances the visual appeal of products, making it perfect for luxury packaging, high-end labels, and decorative items.

Точная высечка

This machine offers advanced die-cutting capabilities, ensuring clean and accurate cuts every time. The precision die cutting feature is crucial for applications that require detailed and flawless finishes, such as printing, packaging, and decorative industries.

Высокоскоростная работа

Designed for efficiency, the BHT 2S1060TMSCE delivers high-speed cutting and stamping performance, significantly increasing production throughput. This high-speed capability is essential for large-scale production environments, ensuring timely completion of substantial orders without compromising on quality.

Advanced Stripping System

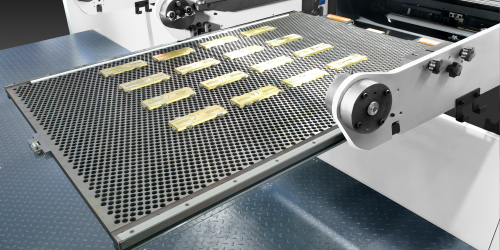

The integrated stripping system automatically removes waste material, streamlining the production process and reducing the need for manual intervention. This feature increases efficiency and ensures a cleaner production environment.

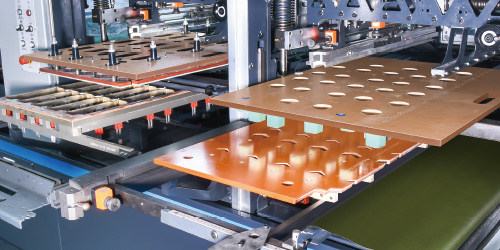

Blanking System

The blanking system further enhances productivity by efficiently separating finished products from waste. This automation reduces manual handling, increasing operational efficiency and ensuring consistent quality.

Robust Construction

Constructed from high-quality materials, the BHT 2S1060TMSCE is designed for durability and stability. Its heavy-duty construction ensures reliable performance under continuous operation, making it suitable for high-volume production tasks.

Удобный интерфейс

Машина имеет интуитивно понятный пользовательский интерфейс, позволяющий операторам легко настраивать и регулировать параметры, контролировать производственный процесс и устранять неполадки. Эта удобная для пользователя конструкция повышает производительность и сокращает время обучения для новых операторов.

Функции безопасности

Safety is a top priority with the BHT 2S1060TMSCE. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Универсальные приложения

The BHT 2S1060TMSCE is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Печать: Выполняем высококачественную штамповку и резку печатной продукции.

- Упаковка: Прецизионная высечка и тиснение фольгой упаковочных материалов.

- Метки и теги: Создание детальных и привлекательных дизайнов этикеток и бирок.

- Декоративное применение: Украшение декоративных изделий замысловатыми вырезами и акцентами из фольги.

Повышение производительности

The integration of high-speed operation, hot stamping, die cutting, stripping, and blanking functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Технологические достижения

The BHT 2S1060TMSCE DUOPRESS stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Заключение

The BHT 2S1060TMSCE DUOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Blanking offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the BHT 2S1060TMSCE delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Частичное введение

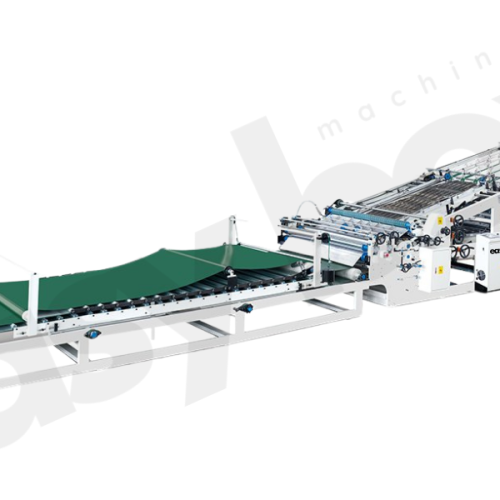

Feeder

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Double sheet detector

Ultrasonic double sheet detector without touching the paper, hence scratch free, reliable and quick set up.

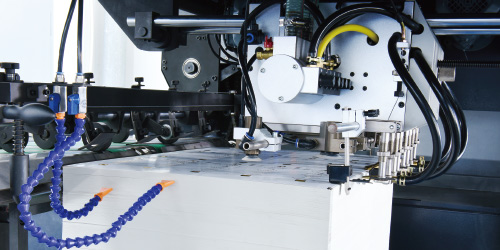

Gripper bar

Gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

Секция горячей штамповки

Max stamping pressure up to 600 tons, which makes it able to achieve better 3D and exquisite effect on large format printing materials such as wine boxes and cigarette boxes.

Plate setting

5mm hardened cutting plate or 4+1mm sandwich plate on top 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and easy make ready.

Mould quick locking device

Adopt center-line system and quick locking device to save make ready time.

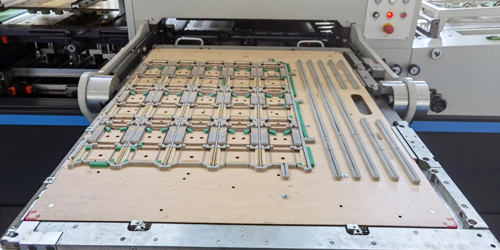

Advanced tooling lockup

Advanced quick tooling set up system ensures fast job change over and hence high productivity at both stripping and blanking stations.

Full sheet delivery

Full sheet delivery option to ensure easy production planning by selecting final delivery style.

Auto separation sheet insert

Automatic separating sheet inserter oupled with electronic position sensor at blanking station.

Non-stop sampling

The Sampling Function can be used to remove a sample sheet on the fly by one button only, easy for operating.

Германия вакуумный насос

Безмасляный воздуходув и вакуумный насос Becker, Германия.

Автоматическая система смазки

Используйте концентрированную автоматическую систему смазки, чтобы обеспечить лучшую работу приводных деталей.

Machine Parameters

| Модель | BHT-2S1060TMSCE |

|---|---|

| Function | 1. hot stamping+die cutting+stripping+blanking |

| Максимальный размер листа | 1060×760мм |

| Минимальный размер листа | 400×350мм |

| Максимальный размер резки | 1060×745mm |

| Maximum Stamping Size | 1060×740mm |

| Минимальный запас захвата | 9~17mm |

| Размер внутреннего паза | 1080×770mm |

| Ассортимент акций | Paper: from 80 to 2000g/m2, 0.1~2mm, |

| Точность высечки | ≤±0.075mm |

| Общая точность штамповки | ≤±0.075mm |

| Точность позиционирования голограммы | ≤±0.075mm |

| Макс. сила вырубки | Press1: 600T, Press2: 300T |

| Макс.рабочая скорость | 7200s/h |

| Maximum Pile Height at Feeder-Normal Mode | 1800mm |

| Maximum Pile Height at Feeder-Non-stop Mode | 1520mm |

| Maximum Pile Height at Delivery | 1580mm |

| Max.gold Foil Diameter | Φ250mm Longitudinal; Φ200mm Transversal |

| Система с электрическим подогревом | 20 Heating zones, 40~180℃Adjustable |

| Ширина фольги | 20~1060mm |

| Press1 Foil Advance Shafts | 3 Longitudinal + 2 Transversal (Optional) |

| Press2 | die cutting+stripping |

| Габариты машины | 12188×5857×2657mm (L×W×H) |

| Чистый вес машины | 44000kg |

| Полная мощность нагрузки | 130KW |

| Потребность в воздухе | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

Отзывы

Отзывов пока нет.