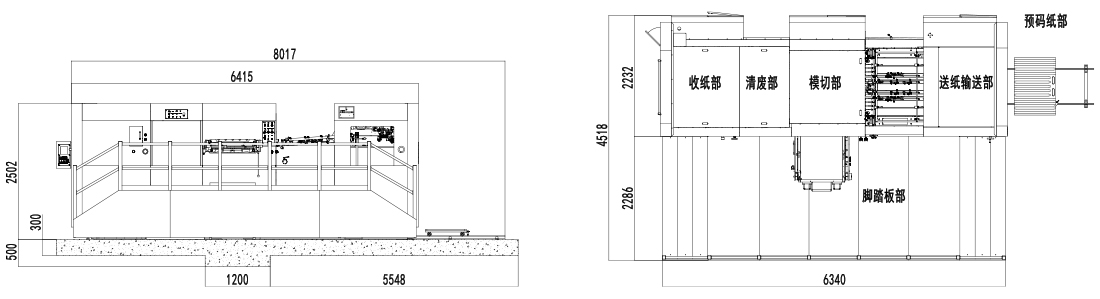

Автоматическая машина для горячего тиснения фольгой и высечки BHT 1060AT (мощная)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Чат WhatsApp

Product Description

BHT 1060AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty): Precision and Durability for High-Demand Applications

The BHT 1060AT Automatic Hot Foil Stamping & Die Cutting Machine is designed for heavy-duty applications, providing exceptional precision, efficiency, and durability. Ideal for industries requiring high-quality stamping and die-cutting, this machine combines advanced technology with robust construction to meet the demands of modern production environments.

Основные характеристики и преимущества

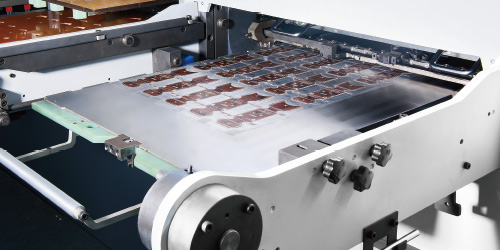

Advanced Hot Foil Stamping

The BHT 1060AT is equipped with a state-of-the-art hot foil stamping system, allowing for high-quality and intricate foil designs. This feature enhances the aesthetic appeal of products, making it ideal for luxury packaging, greeting cards, labels, and more.

High Precision Die Cutting

With its precision die-cutting capabilities, the BHT 1060AT ensures clean and accurate cuts every time. This level of precision is crucial for industries where detail and quality are paramount, such as printing, packaging, and decorative applications.

Прочная конструкция

Constructed from high-quality materials, the BHT 1060AT is built to withstand the rigors of heavy-duty use. Its robust design ensures long-term reliability and stability, allowing it to handle large production volumes with ease.

Automatic Operation

The fully automatic operation of the BHT 1060AT increases efficiency and reduces the need for manual intervention. This automation not only speeds up the production process but also minimizes the risk of human error, ensuring consistent quality across all products.

Удобный интерфейс

The machine features an intuitive user interface that simplifies operation. Operators can easily set up and adjust parameters, monitor the production process, and troubleshoot issues, enhancing overall productivity.

Функции безопасности

Safety is a top priority with the BHT 1060AT. The machine is equipped with multiple safety mechanisms to protect operators and ensure safe operation. These features include emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards.

Универсальные приложения

The BHT 1060AT is suitable for a wide range of materials, including paper, cardboard, plastic sheets, and leather products. This versatility makes it an ideal choice for various industries, including:

- Печать: High-quality stamping and cutting for printed materials.

- Упаковка: Precision die-cutting and foil stamping for packaging materials.

- Метки и теги: Creating intricate designs for labels and tags.

- Декоративное применение: Enhancing decorative items with precise cuts and foil accents.

Высокая скорость работы

The BHT 1060AT is designed for high-speed operation, significantly increasing throughput and reducing production time. This feature is especially beneficial for large-scale production runs, ensuring timely delivery of high-quality products.

Технологические достижения

The BHT 1060AT stands out for its integration of advanced technological features, including precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance overall efficiency, making it a valuable asset for modern manufacturing environments.

Заключение

The BHT 1060AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty) offers an exceptional combination of precision, durability, and advanced automation. Its robust construction, high-speed performance, and user-friendly interface make it an excellent investment for businesses looking to enhance their stamping and die-cutting operations. Whether for printing, packaging, or decorative applications, the BHT 1060AT delivers superior performance and reliability, meeting the high demands of today’s industrial environments.

Рисунок

Частичное введение

Feeder

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Double sheet detector

Ultrasonic double sheet detector without touching the paper, hence scratch free, reliable and quick set up.

Gripper bar

Gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

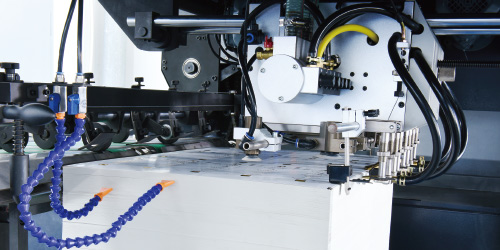

Секция горячей штамповки

Нагревательное основание с 20 зонами нагрева, каждая из которых имеет индивидуальную регулировку температуры для эффективного и точного контроля температуры.

Plate setting

5mm hardened cutting plate or 4+1mm sandwich plate on top 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and easy make ready.

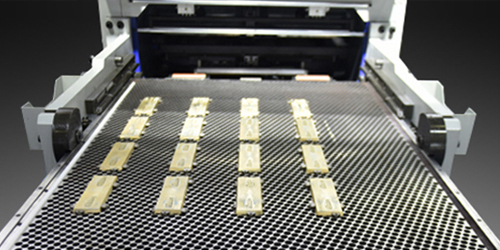

Auto non-stop collecting device

Main collecting device and Auto non-stop collecting device switch automatically without any operation, which make the machine more efficient.

Германия вакуумный насос

Безмасляный воздуходув и вакуумный насос Becker, Германия.

Автоматическая система смазки

Используйте концентрированную автоматическую систему смазки, чтобы обеспечить лучшую работу приводных деталей.

Machine Parameters

| Модель | BHT-1060AT |

|---|---|

| Максимальный размер листа | 1060×760мм |

| Минимальный размер листа | 400×350мм |

| Максимальный размер резки | 1060×745mm |

| Minimum Width of Double Cuts | 5mm |

| Gripper Margin | 9-17мм |

| Cutting Rule Height | 23.8mm |

| Размер внутреннего паза | 1080×770mm |

| Ассортимент акций | Бумага: от 80 до 2000 г/м2, 0,1~2 мм, гофрокартон: до 4 мм |

| Общая точность штамповки | ≤±0.075mm |

| Точность позиционирования голограммы | ≤±0.075mm (选配) |

| Die Cutting Precision | ≤±0.075mm |

| Maximum Cutting Pressure | 600Т |

| Maximum Working Speed | 8000s/h |

| Maximum Pile Height At Feeder | 1630mm (With wooden pallet) |

| Maximum Pile Height At Delivery | 1480mm (With wooden pallet) |

| Max.gold Foil Diameter | 250mm (vertical) |

| Система с электрическим подогревом | 20 Heating zones, 40-180℃ Adjustable |

| Ширина фольги | 20-1060mm |

| Machine Dimensions (L×W×H) | 8017×4518×2762mm (L:paper prepared track included, W:platform included) |

| Net Weight Of Machine | 24T |

| Мощность главного двигателя | 15KW |

| Total Power Required | 56KW |

| Потребность в воздухе | Air pressure: 0.6~0.7Mpa, Flow rate: ≥0.37m3/min |

Отзывы

Отзывов пока нет.