Высокоточный листовой резак CM 1100A/1500A/1700A/1900A с двойным сервоприводом (серия с фотоэлектрическим отслеживанием)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Чат WhatsApp

Product Description

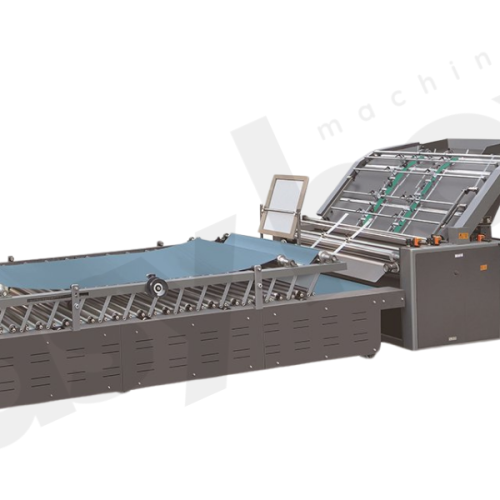

CM 1100A/1500A/1700A/1900A Double Servo Precision High Speed Sheet Cutter (Photoelectric Tracking Series): Advanced Precision and Efficiency

The CM 1100A/1500A/1700A/1900A Double Servo Precision High Speed Sheet Cutter with Photoelectric Tracking represents the pinnacle of cutting-edge technology in industrial sheet cutting. Engineered for high precision, speed, and reliability, this machine series is ideal for various industries requiring meticulous accuracy and efficient operations.

Основные характеристики и преимущества

Double Servo Precision Technology

The CM series machines are equipped with advanced double servo motors, offering unparalleled precision in controlling the cutting process. This dual servo system ensures high-speed operations with exceptional accuracy, making these machines perfect for industries that demand exacting standards.

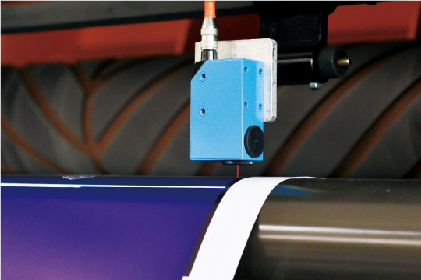

Photoelectric Tracking

One of the standout features of the CM series is the photoelectric tracking system. This technology uses advanced sensors to monitor the position of the material in real-time, ensuring precise alignment and cutting. The photoelectric tracking system significantly reduces errors and ensures consistent quality in every cut.

Высокоскоростная работа

Designed for efficiency, the CM series delivers high-speed cutting performance, significantly boosting productivity. This capability is crucial for industries with large-scale cutting needs, ensuring timely completion of substantial orders without compromising on quality.

High-Quality Construction

Constructed from premium materials and featuring robust engineering, the CM series machines are built for durability and stability. This solid construction allows the machines to handle heavy-duty tasks efficiently and consistently, providing long-term reliable performance.

Four-Shaft Bevel Wheel Structure

The four-shaft bevel wheel structure guarantees steady operation, excellent cutting performance, and low noise levels. This design is particularly suited for various industrial environments where precision and reliability are paramount.

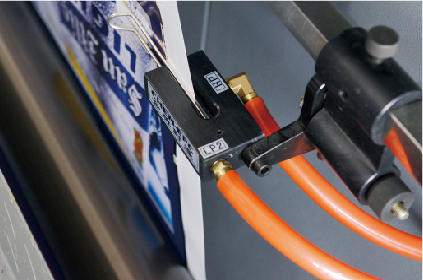

Auto Positioning Slitting System

The auto positioning slitting system is an advanced feature of the CM series. This system automatically adjusts the position of the slitting blades, ensuring consistent and accurate cuts every time. Automation reduces setup time and minimizes human error, leading to increased productivity.

Paper Pre-Press Device

The paper pre-press device ensures proper alignment and pressing of materials before cutting. This feature is essential for achieving high-quality cuts and preventing misalignment or errors during the cutting process.

Three Times Delivery Device (No Impression Line)

The three times delivery device eliminates impression lines on the finished product, ensuring a clean and professional appearance. This feature is especially beneficial for applications requiring high aesthetic standards.

Collecting Board Pneumatic Lifting Device

The collecting board pneumatic lifting device enhances ease of operation by allowing smooth and efficient collection of cut sheets. This pneumatic mechanism reduces manual handling, increasing operator comfort and productivity.

Applications in Various Industries

The CM 1100A/1500A/1700A/1900A Double Servo Precision High Speed Sheet Cutter Machines with Photoelectric Tracking are suitable for a wide range of industries. Their precision cutting capabilities make them ideal for:

- Печать: Ensuring high-quality and precise cuts for printed materials.

- Упаковка: Providing accurate and efficient cutting for packaging materials.

- Paper Products: Handling various types of paper sheets with high precision.

- Commercial Printing: Enhancing productivity and quality in commercial printing operations.

Технологические достижения

The CM series stands out for its integration of advanced technological features, including double servo precision and photoelectric tracking. These innovations streamline the cutting process, reduce downtime, and significantly increase output, making these machines a valuable asset for modern industrial operations.

Заключение

The CM 1100A/1500A/1700A/1900A Double Servo Precision High Speed Sheet Cutter Machines with Photoelectric Tracking offer an exceptional combination of efficiency, precision, and advanced automation. Their robust construction, intelligent functions, and ease of operation make them an excellent investment for businesses looking to enhance their cutting operations. Whether for printing, packaging, or other paper products, the CM series machines deliver superior performance and reliability, meeting the high demands of today’s industrial environments.

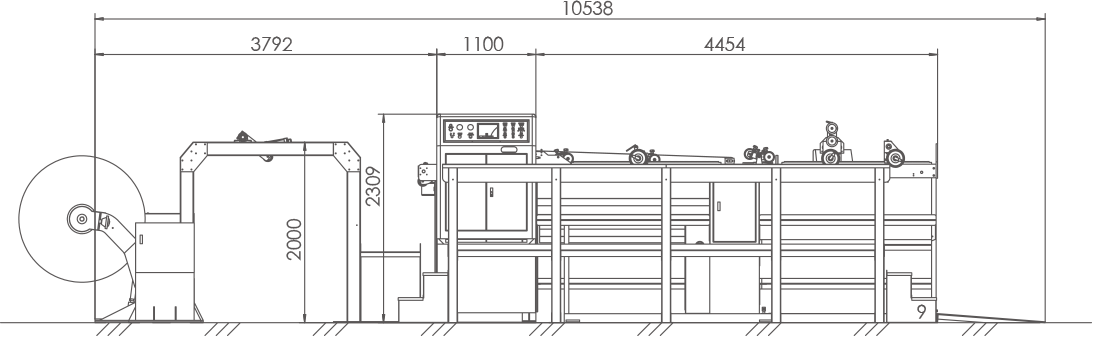

Рисунок

Частичное введение

Photoelectric tracking system

Edge posltion controller system

Machine Parameters

| Модель | CM-1100A |

|---|---|

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm; Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 300cuts/min |

| Max. cutting meter speed | 300m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 9000kgs |

| Full-load Power | 22KW |

| ПРИМЕЧАНИЕ | Одинаковые признаки в таблице записываются как один. |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Отзывы

Отзывов пока нет.