BHT 2S1060RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Чат WhatsApp

Product Description

Introduction to the BHT 2S1060RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System

The BHT 2S1060RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System is an advanced solution designed to revolutionize the packaging and printing industries. Combining precision, speed, and innovative heating technology, this machine ensures superior performance and efficiency, making it an essential asset for high-volume production environments.

Основные характеристики

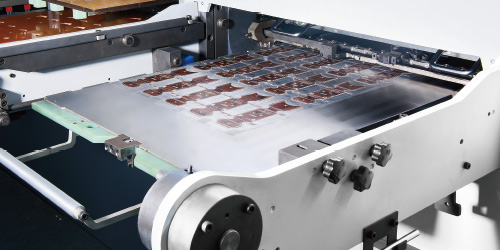

Dual-Press Technology

The DUOPRESS technology integrates dual pressing capabilities, enhancing the die cutting process by enabling simultaneous operations. This feature significantly boosts productivity by reducing cycle times and ensuring consistent, high-quality results.

Высокая точность и достоверность

The BHT 2S1060RMC delivers millimeter-perfect die cutting, ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and ensures superior product quality, essential for maintaining high production standards.

Integrated Heating System

A standout feature of the BHT 2S1060RMC is its integrated heating system. This system ensures smooth and clean cuts, particularly for materials that are challenging to process at room temperature. The heating system also improves creasing results, making it perfect for complex and high-precision tasks.

Высокая скорость работы

Designed for high-speed operations, the BHT 2S1060RMC significantly boosts productivity. Its robust construction and advanced technology enable it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy or quality.

Расширенная автоматизация

The BHT 2S1060RMC features comprehensive automation, including automatic feeding, die cutting, and heating functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

Удобный интерфейс

Интуитивно понятный сенсорный дисплей обеспечивает легкую настройку и мониторинг в реальном времени. Этот удобный интерфейс минимизирует время обучения операторов, обеспечивая плавную и эффективную работу.

Преимущества

- Повышенная эффективность: The combination of high-speed operations, dual-press technology, and an integrated heating system streamlines the workflow, reducing downtime and labor costs.

- Улучшенная безопасность: Equipped with emergency stop buttons and protective guards, the BHT 2S1060RMC ensures a safe working environment, adhering to the highest industry standards.

- Универсальность: Идеально подходит для различных применений, включая упаковку, этикетки, вывески и индивидуальные печатные материалы. Его точность и эффективность делают его ценным активом для предприятий, стремящихся оптимизировать свои производственные процессы и удовлетворять потребности в больших объемах.

Приложения

The BHT 2S1060RMC is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

Влияние отрасли

By integrating the latest technology and automation, the BHT 2S1060RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Заключение

The BHT 2S1060RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System represents a significant advancement in die cutting technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the BHT 2S1060RMC means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

Частичное введение

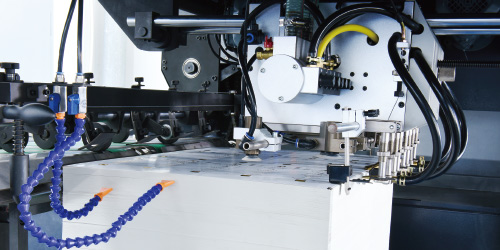

Feeder

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Double sheet detector

Ultrasonic double sheet detector without touching the paper, hence scratch free, reliable and quick set up.

Gripper bar

Gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

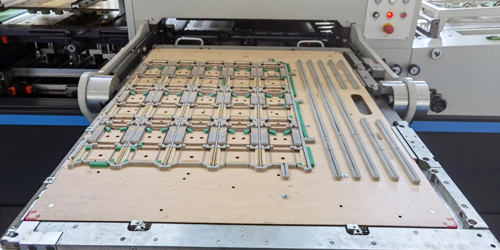

Plate setting

5mm hardened cutting plate or 4+1mm sandwich plate on top 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and easy make ready.

Mould quick locking device

Adopt center-line system and quick locking device to save make ready time.

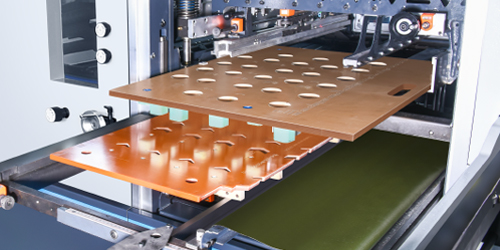

Advanced tooling lockup

Advanced quick tooling set up system ensures fast job change over and hence high productivity at both stripping and blanking stations.

Германия вакуумный насос

Безмасляный воздуходув и вакуумный насос Becker, Германия.

Автоматическая система смазки

Используйте концентрированную автоматическую систему смазки, чтобы обеспечить лучшую работу приводных деталей.

Machine Parameters

| Модель | BHT-2S1060RMC |

|---|---|

| Function | deep embossing+die cutting+stripping |

| Ассортимент акций | Бумага: от 80 до 2000 г/м2, 0,1~2 мм, гофрокартон: до 4 мм |

| Максимальный размер листа | 1060×760мм |

| Минимальный размер листа | Минимальный размер листа |

| Размер внутреннего паза | 1080×770mm |

| Максимальный размер резки | 1060×745mm |

| Maximum Stamping Size | 1060×740mm |

| Минимальный запас захвата | 9~17mm |

| Minimum Width of Double Cuts | 5mm |

| Точность высечки | ≤±0.075mm |

| Макс. сила вырубки | 600ton + 300ton |

| Макс.рабочая скорость | 7200s/h |

| Maximum Pile Height at Feeder-Normal Mode | 1800mm |

| Maximum Pile Height at Feeder-Non-stop Mode | 1520mm |

| Maximum Pile Height at Delivery | 1580mm |

| Система с электрическим подогревом | 20 Heating zones, 40~180℃ Adjustable |

| Press1 Foil Advance Shafts | Electric-heated system |

| Press2 Foil Advance Shafts | die cutting+stripping |

| Machine Dimensions (L×W×H) | 9683×4708×2716mm |

| Machine Dimensions (Including Die Preloader) (L×W×H) | 9683×5608×2716mm |

| Чистый вес машины | 44000kg |

| Полная мощность нагрузки | 48KW |

| Потребность в воздухе | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

Отзывы

Отзывов пока нет.