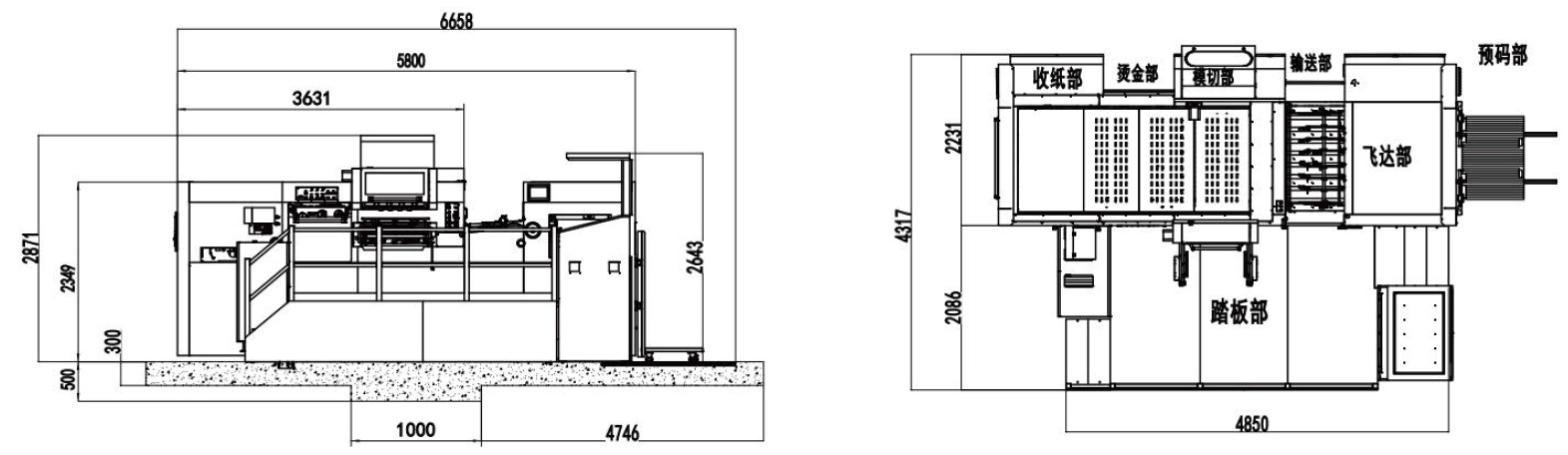

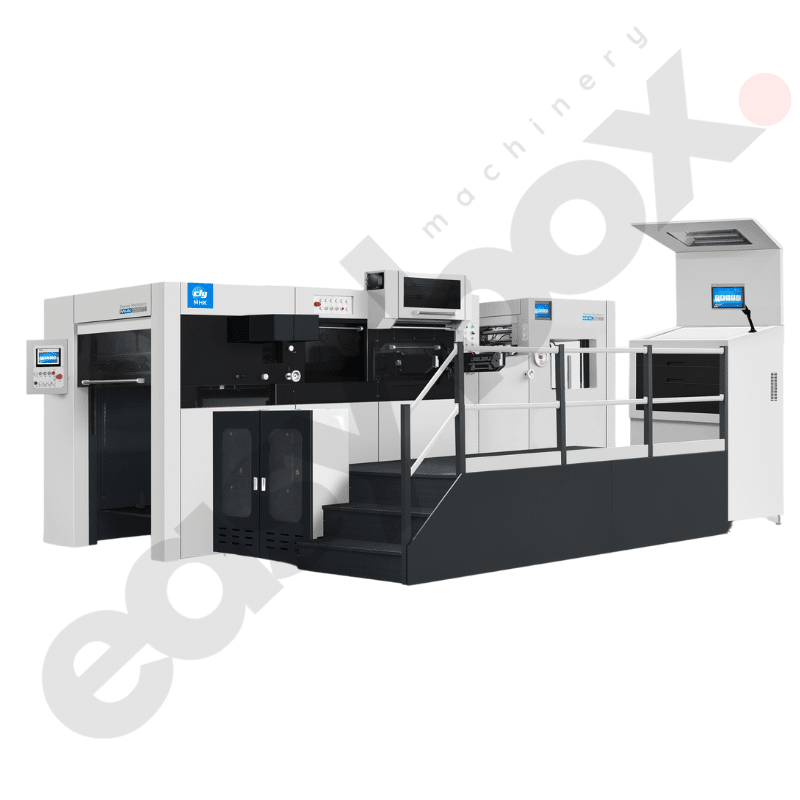

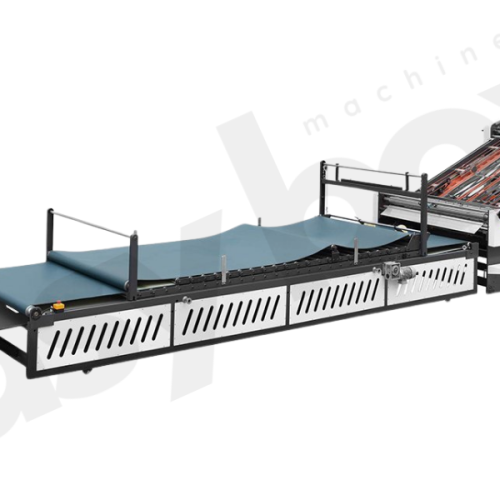

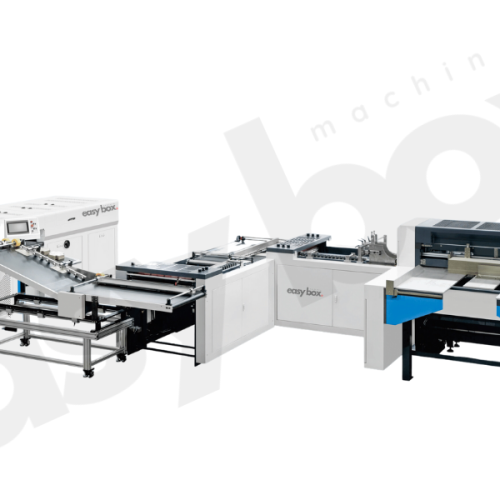

MHK 1050AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty): Excellence in Precision and Performance

The MHK 1050AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty) is engineered to meet the high demands of modern manufacturing. Combining advanced hot foil stamping with precise die cutting, this robust machine offers unmatched efficiency, accuracy, and reliability for various industrial applications.

Key Features and Benefits

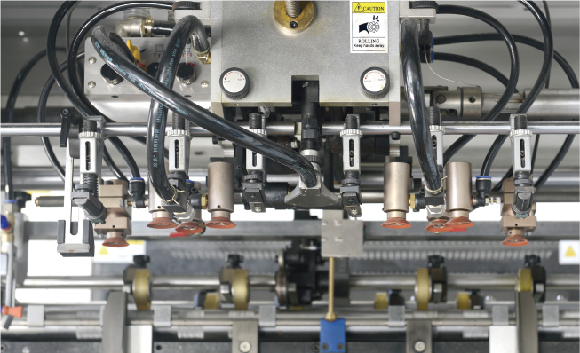

Advanced Hot Foil Stamping System

The MHK 1050AT features an advanced hot foil stamping system, allowing for intricate and high-quality foil designs on a wide range of materials. This capability enhances the visual appeal of products, making it ideal for luxury packaging, high-end labels, and decorative items.

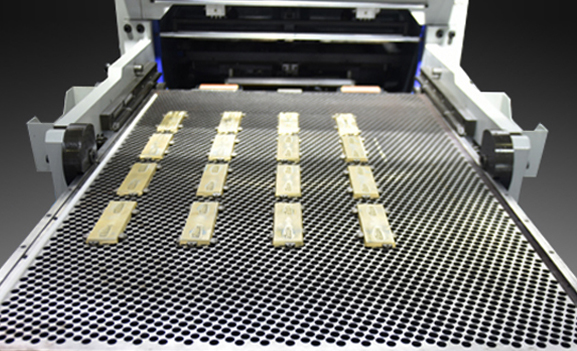

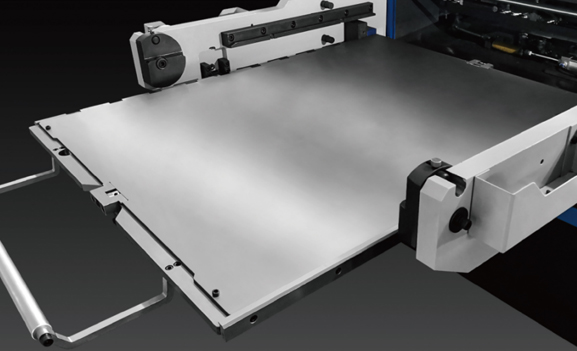

Precision Die Cutting

With its state-of-the-art die-cutting capabilities, the MHK 1050AT ensures clean and precise cuts every time. This level of precision is essential for applications that require detailed and flawless finishes, such as printing, packaging, and decorative industries.

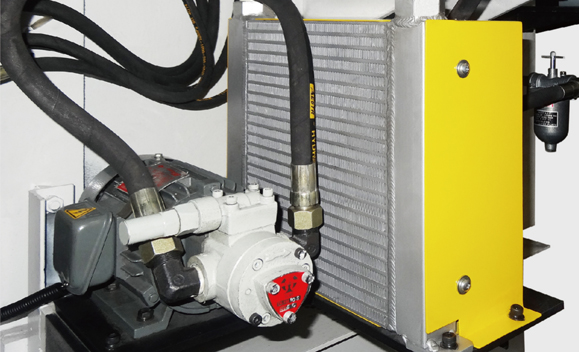

Heavy-Duty Construction

Constructed from high-quality materials, the MHK 1050AT is designed for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks. This robust build ensures long-term durability and consistent performance.

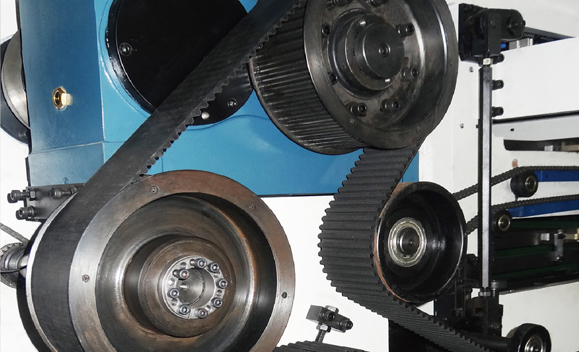

High-Speed Operation

Designed for high-speed performance, the MHK 1050AT significantly increases production throughput. This high-speed capability is crucial for large-scale production environments, ensuring the timely completion of substantial orders without compromising on quality.

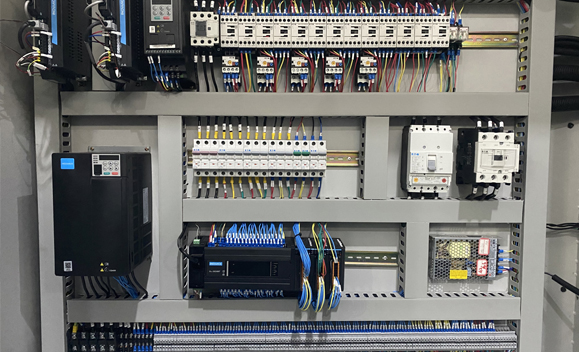

User-Friendly Interface

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Safety Features

Safety is a top priority with the MHK 1050AT. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Versatile Applications

The MHK 1050AT is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Printing: Delivering high-quality stamping and cutting for printed materials.

- Packaging: Providing precise die-cutting and foil stamping for packaging materials.

- Labels and Tags: Creating detailed and attractive designs for labels and tags.

- Decorative Applications: Enhancing decorative items with intricate cuts and foil accents.

Enhanced Productivity

The integration of high-speed operation, hot foil stamping, and die cutting functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Technological Advancements

The MHK 1050AT stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Conclusion

The MHK 1050AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty) offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the MHK 1050AT delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Reviews

There are no reviews yet.