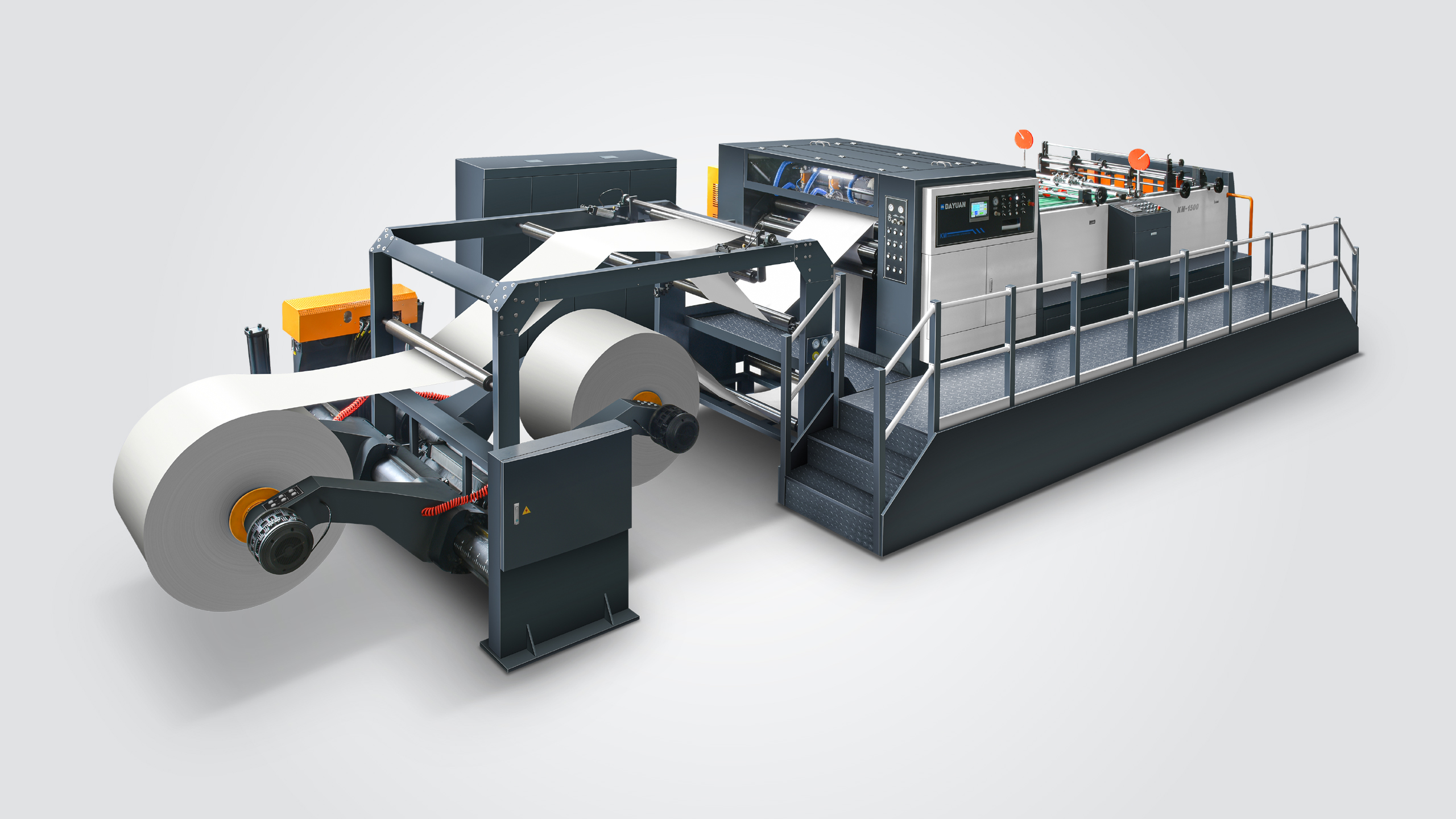

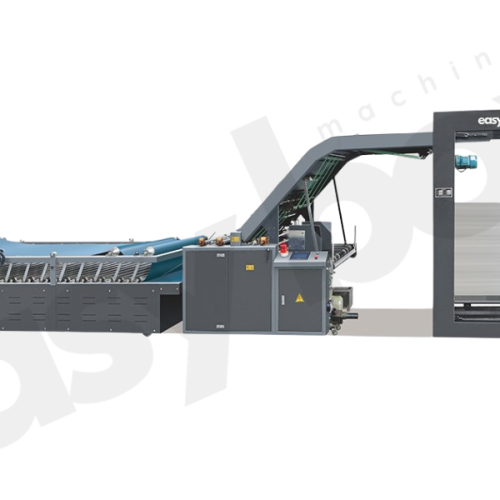

KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine: Precision and Efficiency in Industrial Cutting

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine is designed to meet the demanding needs of various industries requiring high-speed and high-precision sheet cutting. Combining advanced servo technology with a double-helix cutting mechanism, these machines offer unparalleled accuracy, speed, and reliability.

Key Features and Benefits

Advanced Servo Precision Technology

The KM series machines are equipped with state-of-the-art servo motors, providing precise control over the cutting process. This advanced technology ensures high-speed operations with exceptional accuracy, making these machines ideal for industries that demand meticulous precision.

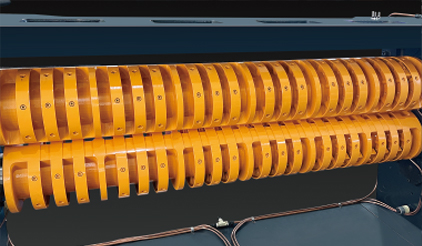

Double-Helix Cutting Mechanism

The innovative double-helix cutting mechanism ensures smooth and clean cuts, significantly reducing the risk of jagged edges or imperfections. This feature enhances the overall quality of the finished product and improves the efficiency of the cutting process.

High-Quality Construction

Constructed from high-quality materials and featuring high-tension casting, the KM series machines are built for durability and stability. This robust construction ensures that the machines can handle heavy-duty tasks efficiently and consistently.

Four-Shaft Bevel Wheel Structure

The four-shaft bevel wheel structure guarantees steady operation, excellent cutting performance, and low noise levels. This design is particularly suited for various industrial environments where precision and reliability are paramount.

Auto Positioning Slitting System

The auto positioning slitting system is an advanced feature of the KM series. This system automatically adjusts the position of the slitting blades, ensuring consistent and accurate cuts every time. This automation reduces setup time and minimizes human error, leading to increased productivity.

Paper Pre-Press Device

The paper pre-press device ensures proper alignment and pressing of materials before cutting. This feature is crucial for achieving high-quality cuts and preventing misalignment or errors during the cutting process.

Three Times Delivery Device (No Impression Line)

The three times delivery device eliminates impression lines on the finished product, ensuring a clean and professional appearance. This feature is especially beneficial for applications requiring high aesthetic standards.

Collecting Board Pneumatic Lifting Device

The collecting board pneumatic lifting device enhances ease of operation by allowing smooth and efficient collection of cut sheets. This pneumatic mechanism reduces manual handling, increasing operator comfort and productivity.

Applications in Various Industries

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machines are suitable for a wide range of industries. Their precision cutting capabilities make them ideal for:

- Printing: Ensuring high-quality and precise cuts for printed materials.

- Packaging: Providing accurate and efficient cutting for packaging materials.

- Paper Products: Handling various types of paper sheets with high precision.

- Commercial Printing: Enhancing productivity and quality in commercial printing operations.

Technological Advancements

The KM series stands out for its integration of advanced technological features, including servo precision and double-helix cutting. These innovations streamline the cutting process, reduce downtime, and significantly increase output, making these machines a valuable asset for modern industrial operations.

Conclusion

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machines offer an exceptional combination of efficiency, precision, and advanced automation. Their robust construction, intelligent functions, and ease of operation make them an excellent investment for businesses looking to enhance their cutting operations. Whether for printing, packaging, or other paper products, the KM series machines deliver superior performance and reliability, meeting the high demands of today’s industrial environments.

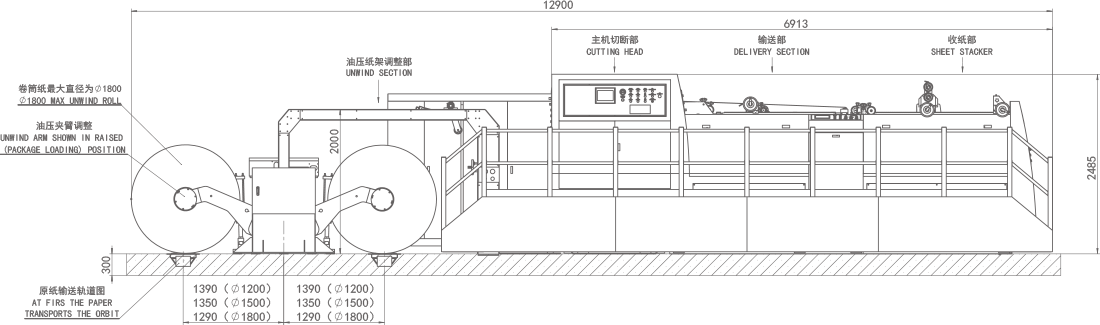

Drawing

Partial Introduction

Embedded double helix knife (Invention patent)

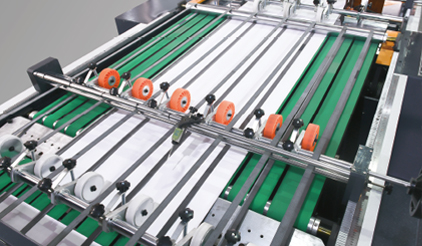

Slitting knifes (Optional)

Conveying unit

Additional information

| Model | KM-1100 |

|---|---|

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-800gsm |

| Cutting length range | 450-1650mm |

| Cutting precision (1 roll) | Cutting length≤1000mm: ±0.1mm |

| Max. cutting meter speed | 330m/min |

| Max. cutting speed | 540cuts/min |

| Max. scroll diameter | 1500mm(KM-1100) |

| Max. paper cutting width | 1100(45”)mm |

| Max. paper piling height | 1300mm(KM-1100) |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| G.W. (1 roll) | 16000kgs |

| Full-load Power | 69kw |

| NOTE | Features that are the same in the table are written as one. |

Reviews

There are no reviews yet.