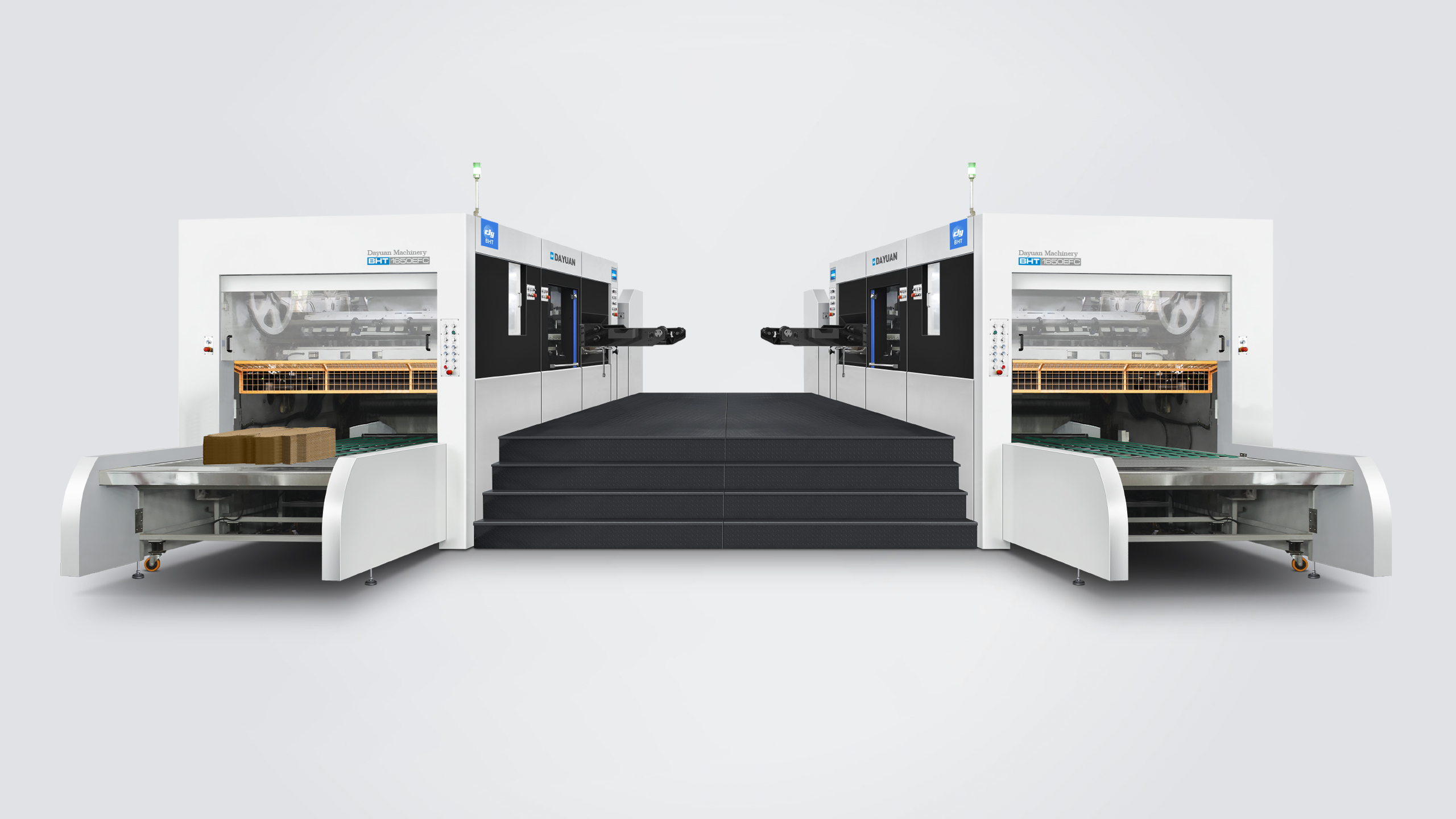

BHT 1650EFC/1900EFC/2100EFC Mirror Machines Dual Diecutter Working Station(Down Feeder)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

Advantages of the Mirror Machines Dual Diecutter Working Station

The Mirror Machines Dual Diecutter Working Station is designed to enhance efficiency and reduce costs in modern manufacturing processes. Here are the main advantages of this advanced system:

Simultaneous Operation

Two flat die cutting machines operate in tandem, ensuring that feeding and collecting are synchronized. This parallel operation streamlines the workflow, reducing complexity and improving overall efficiency.

Shared Resources

Both die cutting machines utilize the same foot pedals, knife setup, stripping, waste clearance system, plates, frames, and switchboard functionality. This integration means that components are shared across both machines, leading to significant cost savings by eliminating the need for duplicate equipment.

Lower Labor Costs

With only one operator needed per shift to manage both die cutting machines, labor costs are significantly reduced. The machines are arranged face-to-face, allowing the operator to oversee the entire process easily. This layout enables quick identification and resolution of any issues, thus improving production yield and efficiency.

Flexible and Interchangeable Installation

The system’s design allows for flexible installation and easy interchangeability of the plate frames. The shared switchboard and frame system mean that components can be installed and adjusted freely, simplifying maintenance and enhancing adaptability.

Unified Positioning System

A central positioning system standardizes the setup, allowing all molds to be shared between the machines. This uniformity simplifies the process and increases the versatility and efficiency of the production line.

Space and Cost Efficiency

The dual-unit die cutting machine configuration, featuring positive and negative (left and right) hand units, maximizes floor space utilization. This efficient design aids in better space planning and leads to higher investment efficiency, making it an ideal choice for businesses aiming to optimize their production environment.

Conclusion

The Mirror Machines Dual Diecutter Working Station offers synchronized operations, shared resources, reduced labor costs, flexible installation, and efficient use of space. These features make it an excellent solution for companies looking to improve productivity, cut costs, and make the best use of their manufacturing space. Adopting this advanced die cutting technology can result in substantial enhancements in operational efficiency and product quality.

Area Saving

| 2 Regular Machines Floor Space | Mirror Machines Floor Space | Total Space Saved | |

| With Chase Loader | 197.3m² | 148.5m² | 48.8m² |

| Without Chase Loade | 172.2m² | 142.8m² | 27.4m² |

Because the same foot pedal is shared, the intermediate channel (at least 2×10 meters) when the two machines are placed separately, can save 2×10=20m2 of plant occupation area.

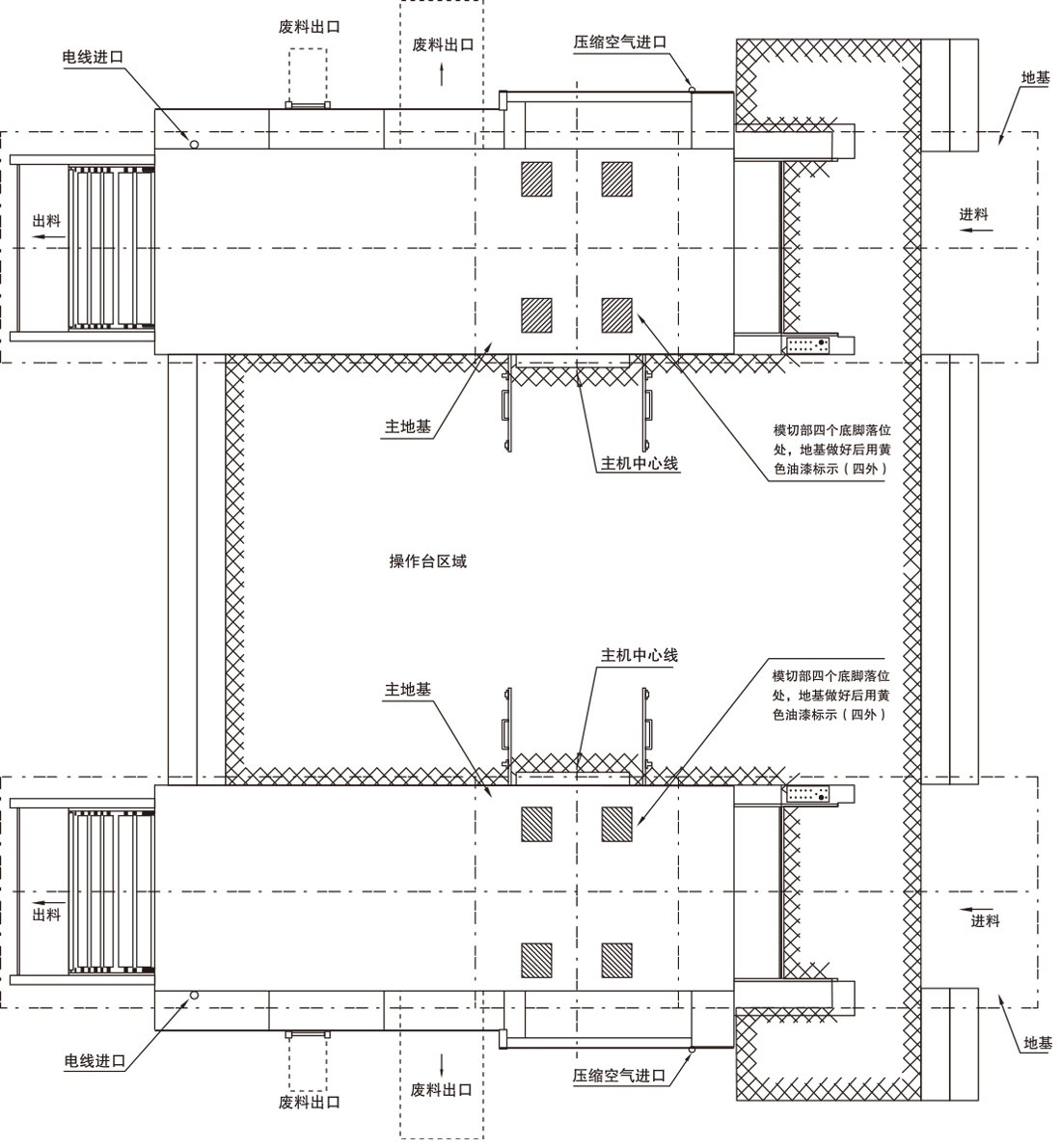

Drawing

Reviews

There are no reviews yet.