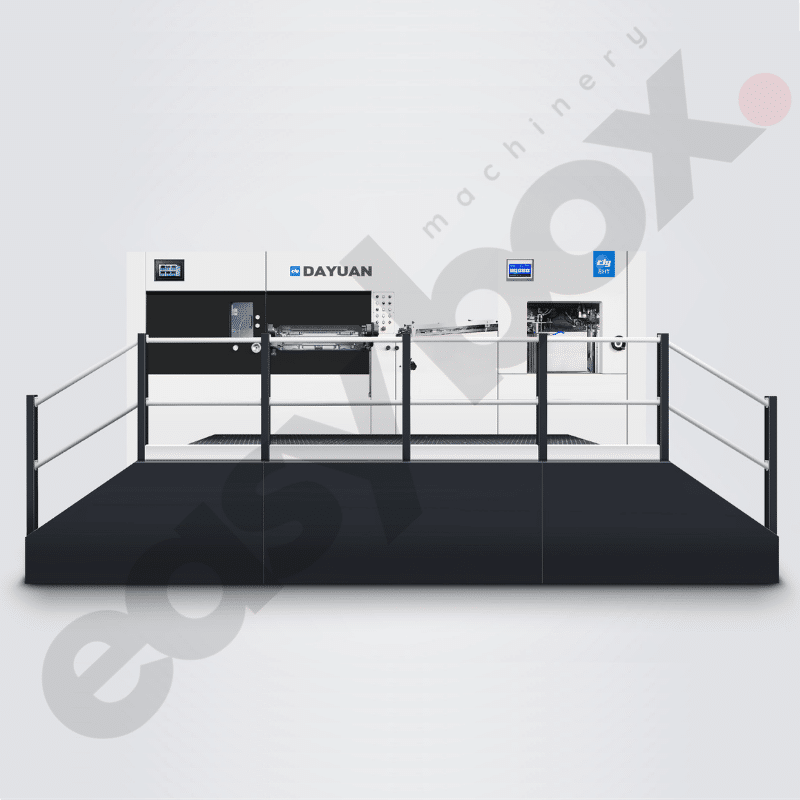

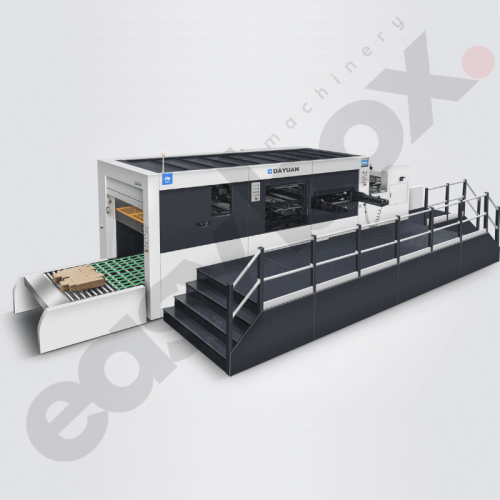

BHT 1060AR Automatic Die Cutting Machine (Heavy duty, Heating system)

$99,999.00

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Description

Introduction to the BHT 1060AR Automatic Die Cutting Machine (Heavy Duty, Heating System)

The BHT 1060AR Automatic Die Cutting Machine (Heavy Duty, Heating System) is an innovative solution designed to meet the rigorous demands of the packaging and printing industries. This advanced machine integrates high precision, durability, and a specialized heating system to enhance the die cutting process, making it ideal for high-volume production environments.

Key Features

High Precision and Accuracy

The BHT 1060AR delivers exceptional precision in die cutting, ensuring millimeter-perfect results. This high level of accuracy is crucial for applications requiring detailed and exact specifications, improving overall product quality and minimizing material waste.

Heavy Duty Performance

Engineered for heavy-duty operations, the BHT 1060AR is built to withstand intensive use. Its robust construction guarantees long-term reliability and consistent performance, even under the most demanding production conditions.

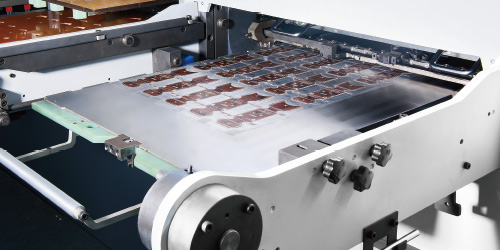

Integrated Heating System

One of the standout features of the BHT 1060AR is its integrated heating system. This system enhances the die cutting process by ensuring smooth and clean cuts, especially useful for materials that are difficult to process at room temperature. The heating system also helps in achieving better creasing results.

Benefits

- Enhanced Productivity: The combination of high-speed operation and the integrated heating system significantly boosts productivity, allowing for efficient large-scale production.

- User-Friendly Interface: The machine features an intuitive touch-screen display for easy setup and real-time monitoring, reducing the learning curve for operators and ensuring smooth operation.

- Safety Features: Equipped with emergency stop buttons, protective guards, and real-time monitoring systems, the BHT 1060AR ensures a safe working environment, adhering to the highest industry standards.

Applications

The BHT 1060AR is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its heavy-duty capabilities and integrated heating system make it particularly suitable for businesses seeking to optimize their production processes and handle complex materials.

Conclusion

The BHT 1060AR Automatic Die Cutting Machine (Heavy Duty, Heating System) sets a new benchmark in the industry with its combination of precision, durability, and innovative heating technology. Designed to meet the needs of modern manufacturing, it helps businesses increase productivity while maintaining high quality and safety standards.

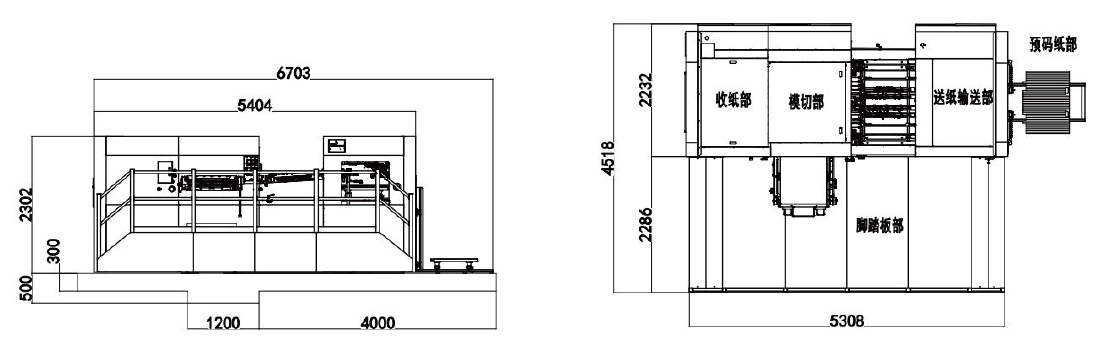

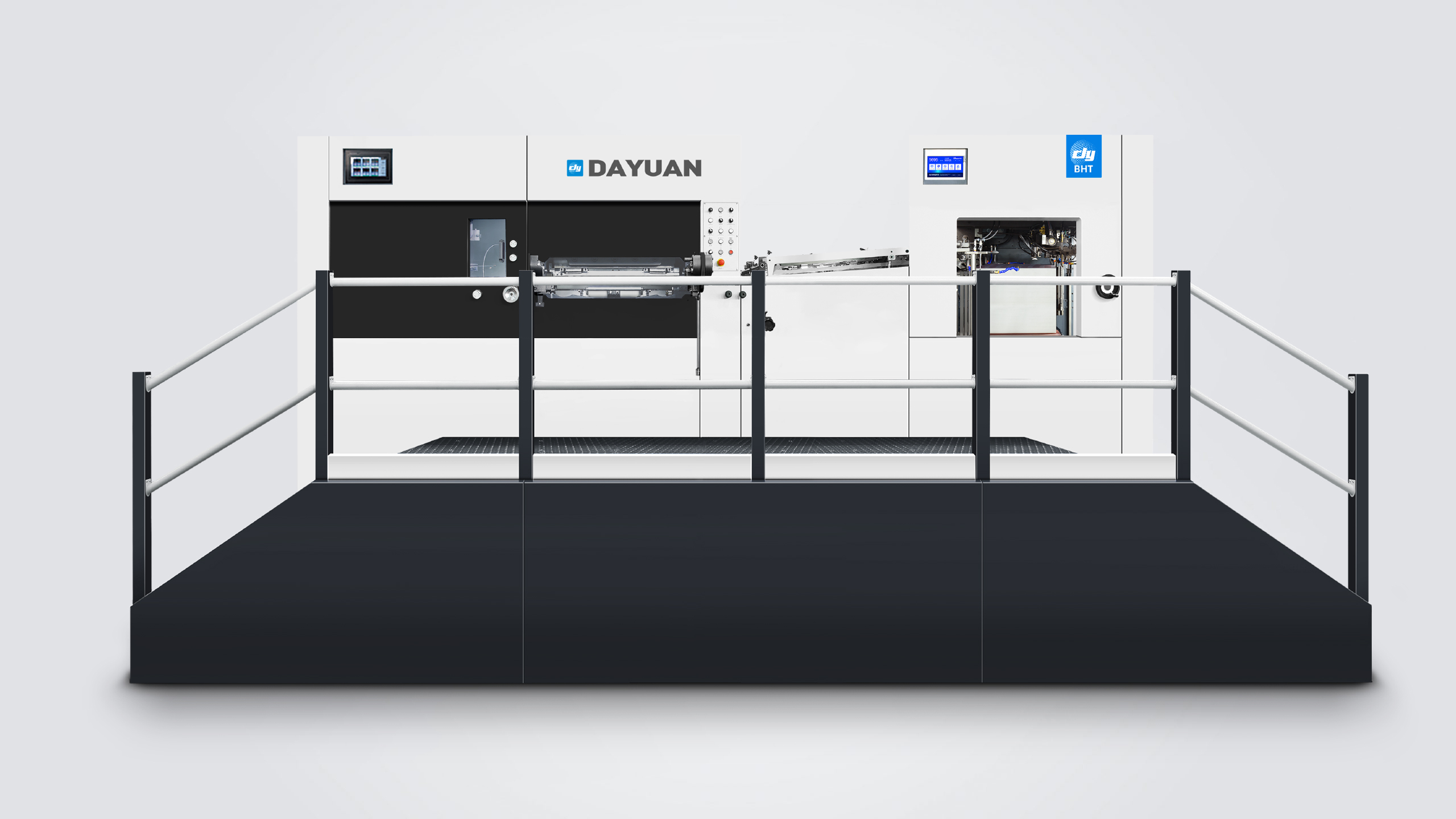

Drawing

Partial Introduction

Feeder

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Double sheet detector

Ultrasonic double sheet detector without touching the paper, hence scratch free, reliable and quick set up.

Gripper bar

7 gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

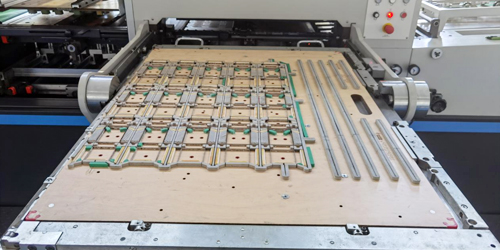

Plate setting

5mm hardened cutting plate or 4+1mm sandwich plate on top 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and easy make ready.

Auto non-stop collecting device

Main collecting device and Auto non-stop collecting device switch automatically without any operation, which make the machine more efficient.

Mould quick locking device

Adopt center-line system and quick locking device to save make ready time.

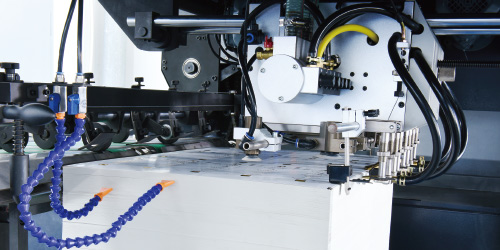

Germany vaccum pump

Germany Becker oil free blower and vacuum pump.

Auto lubrication system

Adopt concentrated auto lubrication system to make sure the driven parts working better.

Additional information

| Model | BHT-1060AR |

|---|---|

| Maximum Sheet Size | 1060×760mm |

| Minimum Sheet Size | 400×350mm |

| Maximum Cutting Size | 1060×745mm |

| Minimum Width of Double Cuts | 5mm |

| Gripper Margin | 9-17mm |

| Cutting Rule Height | 23.8mm |

| Inner Chase Size | 1080×770mm |

| Stock Range | Paper: from 80 to 2000g/m2, 0.1~2mm, corrugated board: up to 4mm |

| Die Cutting Precision | ≤±0.075mm |

| Maximum Cutting Pressure | 600T |

| Maximum Working Speed | 8000s/h |

| Maximum Pile Height at Feeder | 1630mm (With wooden pallet) |

| Maximum Pile Height at Delivery | 1480mm (With wooden pallet) |

| Electric-heated system | 20 Heating zones, 40-180℃ Adjustable |

| Machine Dimensions (L×W×H) | 6703×4518×2502mm (L:paper prepared track included, W:platform included) |

| Net Weight of Machine | 21T |

| Main Motor Power | 15KW |

| Total Power Required | 35KW |

| Air Requirement | Air pressure: 0.6~0.7Mpa, Flow rate: ≥0.37m3/min |

Reviews

There are no reviews yet.