MHK 3S1050TRMC TRIOPRESS 自動高速ホットスタンプ&ダイカッティングマシン(ストリッピング&加熱システム付き)

(+86) 158 9968 3398 WhatsApp チャット

Product Description

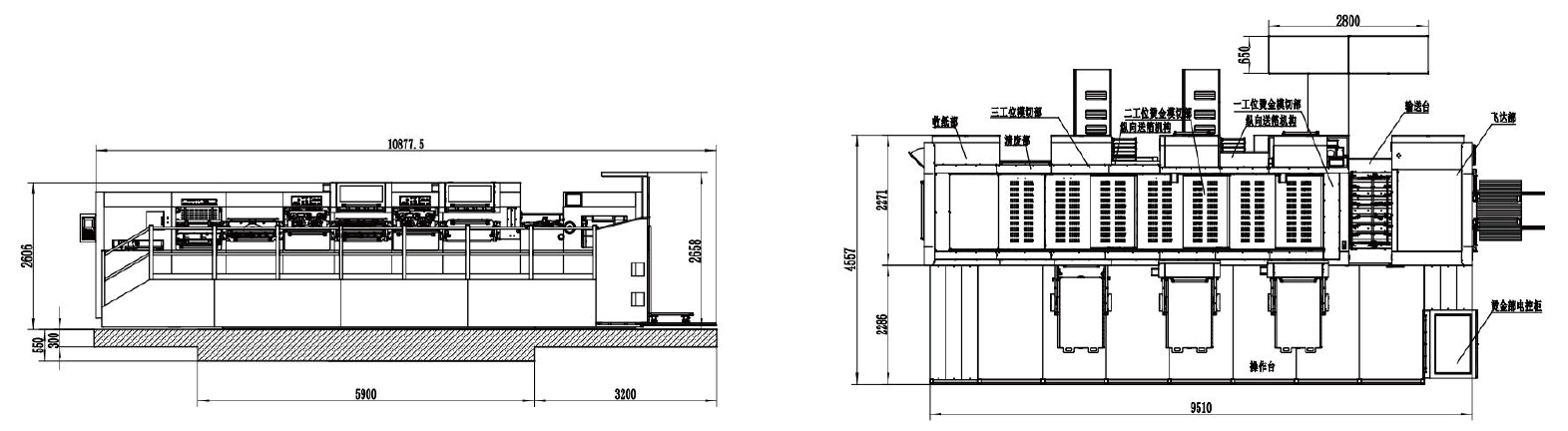

描画

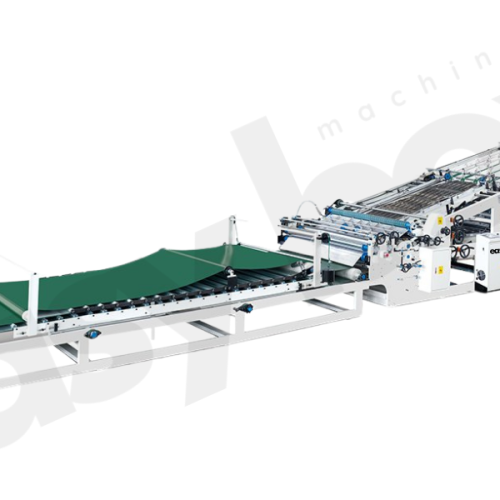

MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System: Efficiency and Precision in One Pass

The MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System is a state-of-the-art solution designed for the high demands of modern post-press operations. By integrating multiple processes into a single seamless operation, this machine offers exceptional precision, efficiency, and reliability.

主な機能と利点

One-Pass Multi-Process Capability

The MHK 3S1050TRMC TRIOPRESS can perform multiple processes in one pass, significantly enhancing production efficiency and reducing labor costs. The machine’s capabilities include:

- Hot Stamping + Deep Embossing + Die Cutting + Stripping: Achieve intricate and high-quality foil designs, deep embossing, precise die cutting, and efficient stripping in a single operation.

- Deep Embossing + Deep Embossing + Die Cutting + Stripping: Combine multiple deep embossing processes with die cutting and stripping for superior texture and detail.

Precision and Efficiency

The MHK 3S1050TRMC TRIOPRESS stands out with its ability to accurately register multiple processes in one pass, a capability that traditional machines often cannot match. This precision ensures high-quality results and maximizes production efficiency.

Robust Construction and Design

Constructed from high-quality materials, the MHK 3S1050TRMC is built for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

ユーザーフレンドリーなインターフェース

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Advanced Heating System

The integrated heating system ensures consistent and precise temperature control, which is essential for high-quality hot stamping and deep embossing. This feature enhances the machine’s overall reliability and performance, ensuring uniform results across all production runs.

Efficient Stripping System

The efficient stripping system automatically removes waste material, streamlining the production process and reducing the need for manual intervention. This feature increases efficiency, ensures a cleaner production environment, and enhances the overall quality of finished products.

安全機能

Safety is a top priority with the MHK 3S1050TRMC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

多用途アプリケーション

The MHK 3S1050TRMC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- 印刷: Delivering high-quality stamping, embossing, and cutting for printed materials.

- パッケージ: Providing precise die-cutting, foil stamping, and stripping for packaging materials.

- ラベルとタグ: Creating detailed and attractive designs for labels and tags.

- 装飾用途: Enhancing decorative items with intricate cuts, foil accents, and embossing.

生産性の向上

The integration of high-speed operation, hot stamping, deep embossing, die cutting, and stripping functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

技術の進歩

The MHK 3S1050TRMC TRIOPRESS incorporates advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

結論

The MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their post-press processes. Whether for printing, packaging, or decorative applications, the MHK 3S1050TRMC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

部分的な紹介

フィーダーユニット

Four pick up and four forward suck heads with angle adjustment to handle different kinds of materials.

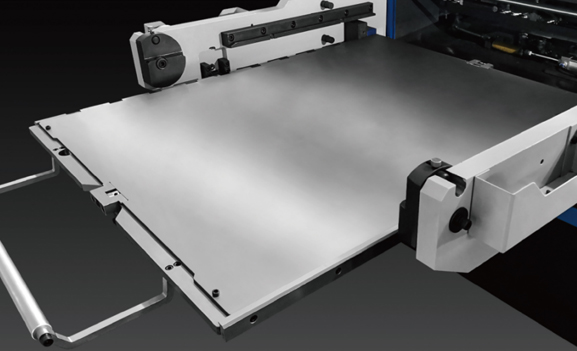

給餌テーブル

生産時にシートの位置をフロントレイに手動で調整する同期装置、シート押さえ装置(シートをフロントレイにガイドする)。

ホットスタンプ部門

20 の加熱ゾーンを備えた加熱ベース。各ゾーンの温度を個別に調整できるため、効率的かつ正確な温度制御が可能です。

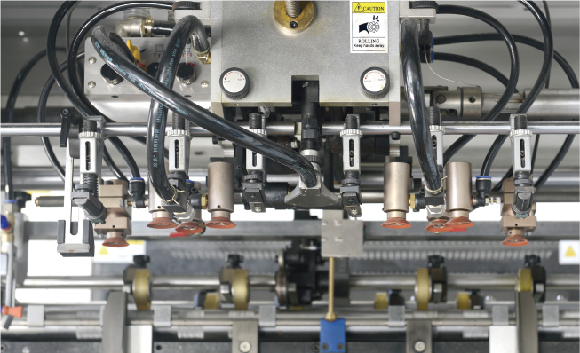

Foil advancing unit

Three sets of longitudinal foil advancing shafts and two sets of lateral foil advancing shafts are driven by servo motors individually programmable for short and long foil stepping.

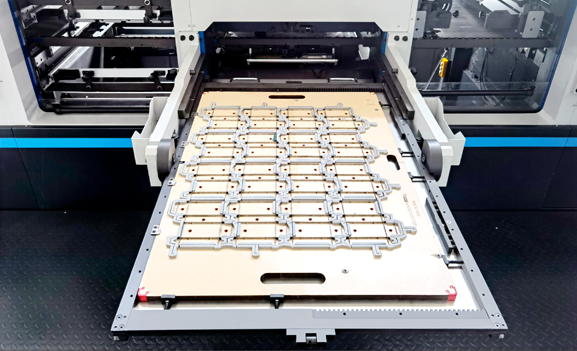

Mould quick locking device

Adopt Center-line system and quick locking device to save make ready time.

プレートセッティング

5mm hardened stamping plate or 3.5mm + 1.5mm sandwich stamping plate on top of 15mm precision ground supporting base plate with +/-0.9mm micro adjustment in both running and cross direction for quick set up and easy make ready.

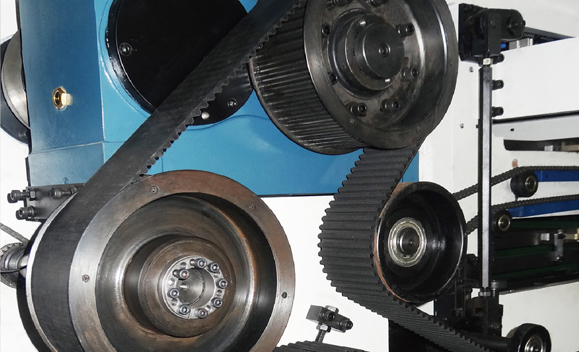

トルクリミッター

台湾の高精度な間欠セグメンテーションにより、長期間の使用でも高い位置精度が保証されます。

台湾のトルクリミッターは、敏感な制限保護性能により、人為的な操作事故を正確に防ぎ、人と機械の安全を保証します。

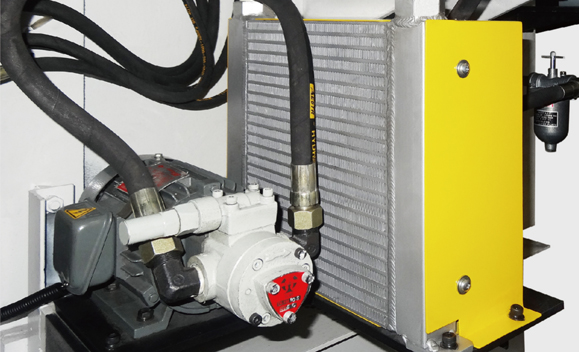

主モーター潤滑システム

台湾製の自動オイルポンプ冷却循環システムにより、メインモーターの高速潤滑を長時間にわたって確保します。

油圧計、油圧警報装置を装備。

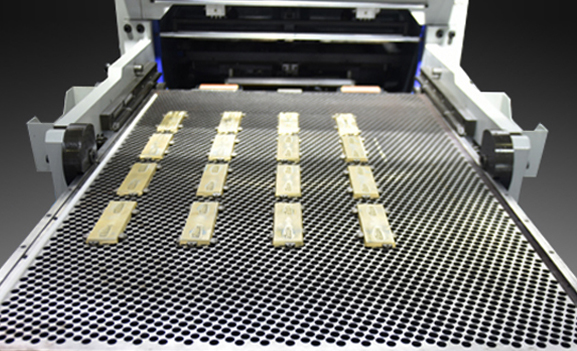

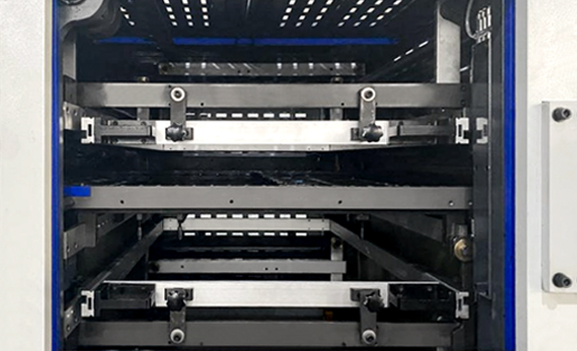

剥離ユニット

センターラインシステムを採用し、上部と下部のストリッピングツール取り付けフレームを引き出して作業のセットアップと準備を行うことができます。

Gripper edge waste removal device

Gripper edge stripping and removing system with conveyor belt to remove the gripper edge waste sideways to the drive side.

配送ユニット

ノンストップカーテンによる自動搬送。このカーテンは搬送部に移動し、パイル交換中に到着した用紙をキャッチします。用紙収集用の 2 つのブロワーにより、薄い紙と厚い紙をきれいに収集できます。

ドイツ真空ポンプ

ドイツ ベッカー社のオイルフリーブロワーと真空ポンプ。

自動潤滑システム

駆動部品の動作を向上するために、集中自動潤滑システムを採用しています。

Machine Parameters

| モデル | MHK-3S1050TRMC |

|---|---|

| Function | 1. hot stamping+deep embossing+die cutting+stripping |

| 最大シートサイズ | 1050×750mm |

| 最小シートサイズ | 400×360mm |

| 最大切断サイズ | 1040×720mm |

| Max. Hot Stamping Size | 1040×720mm |

| Max. Embossing Area | 1040×720mm |

| 最小グリッパーマージン | 9~17mm |

| 内側チェイスサイズ | 1140×755mm |

| 在庫範囲 | 紙:80~2000g/m2、0.1~2mm、段ボール:最大4mm |

| ダイカット精度 | ≤±0.075mm |

| 一般的な刻印精度 | ≤±0.075mm |

| ホログラム位置決め刻印精度 | ≤±0.075mm(optional) |

| Embossing Accuracy | ≤±0.075mm |

| Max. Die Cutting Force | Press1: 600T, Press2: 600T, Press3: 300T |

| 最大動作速度 | 6200s/h (Die cutting), 6200s/h (Hot stamping), 6200s/h (Hot pressing) |

| Max. Feeder Pile Height | 1600mm(With wooden pallet) |

| Max. Delivery Pile Height | 1400mm(With wooden pallet) |

| Max. Gold Foil Diameter | Ф250mm Longitudinal, Ф200mm Transversal |

| 電気加熱システム | 20 temperature ranges, 40-180℃ is adjustable |

| フォイル幅 | 20~1020mm |

| Press1 Foil Advance Shafts | 3 Longitudinal+2 Transversal (optional) |

| Press2 | Equipped with electric heating system |

| Press3 | die cutting+stripping |

| 機械寸法 | 10878×4557×2658mm(L×W×H) (L: paper prepared track included, W: platform included) |

| 機械の正味重量 | 44T |

| 全負荷ワット数 | 99KW |

| 空気要件 | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

レビュー

レビューはまだありません。