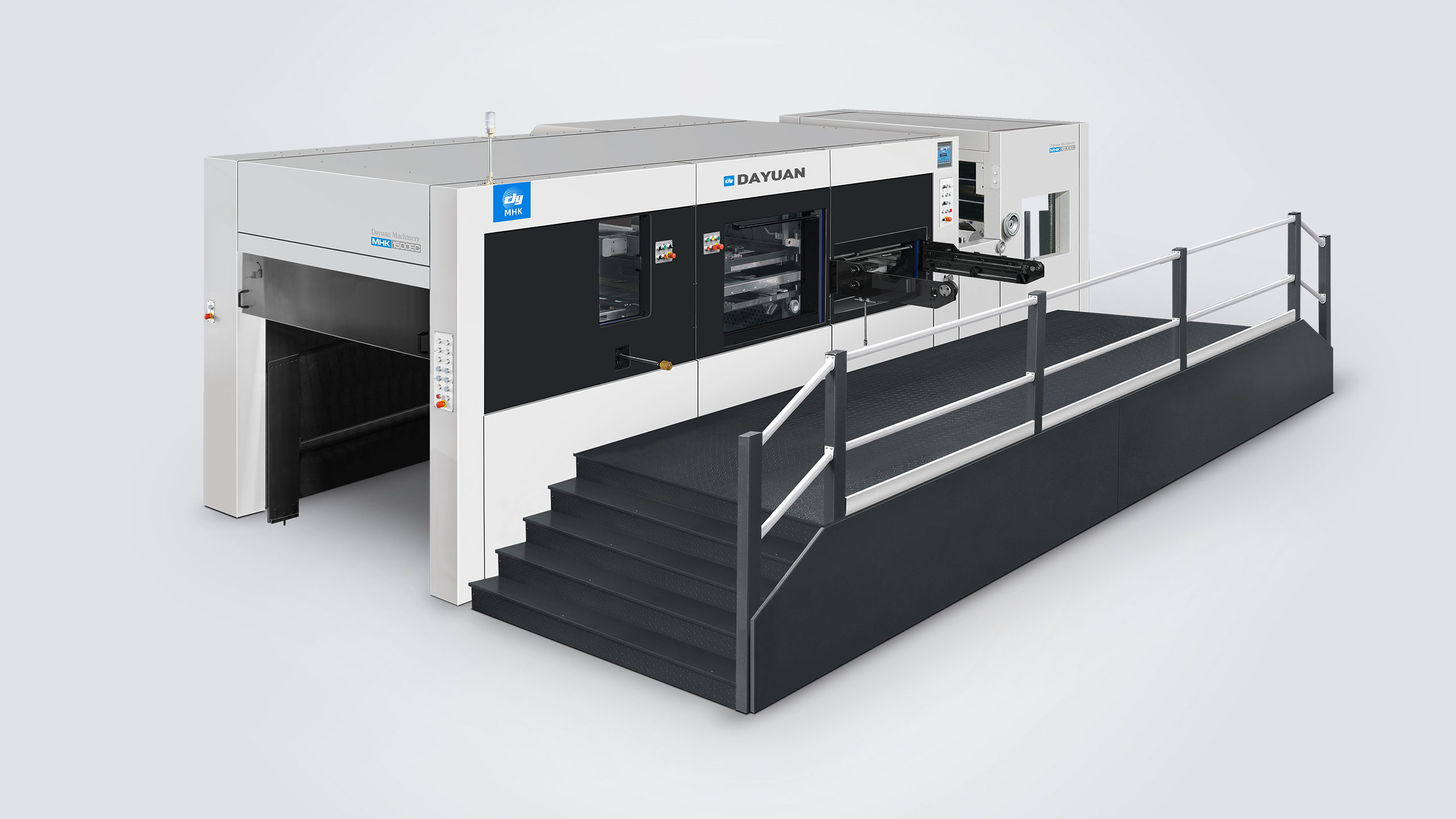

MHK 1300EC/1500EC ストリッピング機能付き自動ダイカットマシン

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsAppチャット

Product Description

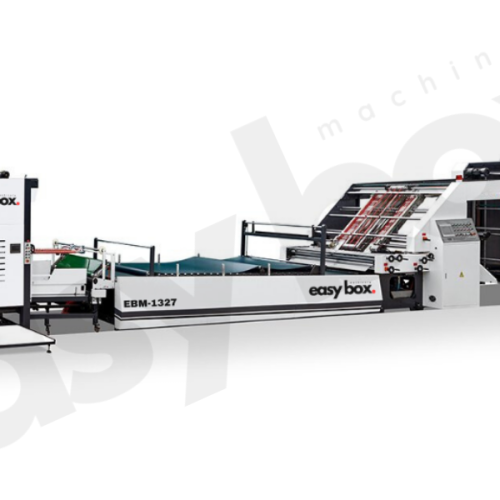

Introduction to the MHK 1300EC/1500EC Automatic Die Cutting Machine with Stripping

The MHK 1300EC/1500EC Automatic Die Cutting Machine with Stripping is a state-of-the-art solution designed to enhance precision and efficiency in the packaging and printing industries. This advanced machine integrates die cutting and stripping functionalities, ensuring superior performance and high productivity.

主な特徴

高精度と正確性

The MHK 1300EC/1500EC delivers millimeter-perfect die cutting, making it ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and ensures superior product quality, which is essential for maintaining high production standards.

統合されたストリッピング機能

A standout feature of the MHK 1300EC/1500EC is its integrated stripping functionality. This system automatically removes waste material from the finished product, ensuring clean and precise edges. The stripping function reduces manual labor and accelerates the production process, leading to significant labor cost savings.

高速パフォーマンス

Designed for high-speed operations, the MHK 1300EC/1500EC significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy.

ユーザーフレンドリーなインターフェース

The machine features an intuitive touch-screen display that provides easy setup and real-time monitoring, minimizing the learning curve for operators and ensuring smooth operation.

利点

- 効率の向上: 高速操作と統合された剥離機能の組み合わせにより、ワークフローが合理化され、ダウンタイムと人件費が削減されます。

- 安全性の向上: 緊急停止ボタンと保護ガードが装備されたこの機械は、業界最高水準に準拠した安全な作業環境を保証します。

- Versatility: Suitable for a variety of applications, including packaging, labels, signage, and custom print materials. Its precision and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

アプリケーション

The MHK 1300EC/1500EC is perfect for various applications, including packaging, labels, signage, and custom print materials. Its versatility and precision make it a valuable asset for businesses aiming to optimize their production processes and meet high-volume demands.

結論

The MHK 1300EC/1500EC Automatic Die Cutting Machine with Stripping sets a new industry standard with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, this machine helps businesses increase productivity while maintaining high quality and safety standards.

Features Introduced

Feeder

Sheet transmission and alignment section

Selectable left and right side push lays to ensure accurate alignment.

Advanced non-stop adjustment of feeding timing, reduce down time.

Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

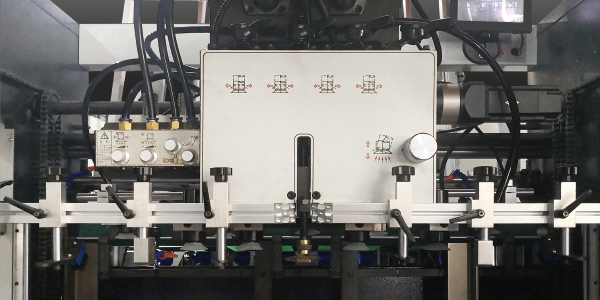

Die cutting section

Die cutting station safety door and pneumatic die chase safety locking system.

Air cushion underneath the cutting plate for easy sliding through.

Main drive adopts high quality precision worm gear and toggle system.

New technology of driving index with large motion angle to allow gripper bar gentle start and stop, less and smaller nicks required to achieve higher productivity. Equipped with overloading protection torque limit clutch.

Cutting pressure fine adjustment wheel with position indicate gauge.

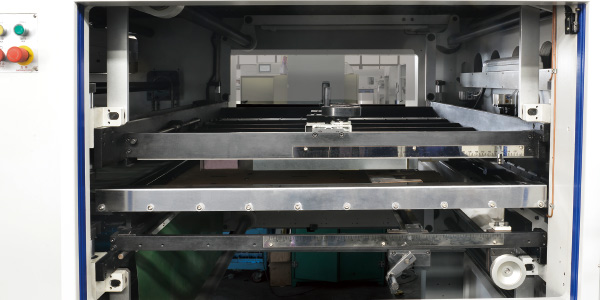

Stripping section

Stationary middle stripping board, coupled with zero jerk, smooth upper frame motion curve with extra punch at the moment of impact to obtain cleaner waste removal.

Gripper bar register block at outlets of Stripping Station ensures the accuracy of stripping.

Center line system for quick stripping tool set up and change over, compatible with centerline.

Front edge waste removal system removes and transfers waste edge outside the machine via conveyor belt.

Gripper edge waste removal device

Gripper edge stripping and removing system with conveyor belt to remove the gripper edge waste sideways to the drive side.

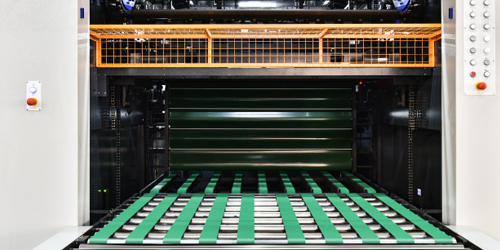

Paper counting & collecting section(Optional)

Escalator delivery fork cooperate with non-stop air cylinder for neat and positive conveying to belt table. Bundle Delivery table is ready for further connection with Breaker for inline operation (to be required at order).

Electrical batch counter as standard.

Spring loaded adjustable chain tensioner for maintaining constant tension thus reducing stress on chains and producing smooth gripper bar movement.

Auto Non-stop Collecting Device(Optional)

Germany vaccum pump

ドイツ ベッカー社のオイルフリーブロワーと真空ポンプ。

自動潤滑システム

Adopt concentrated auto lubrication system to make sure the driven parts working better.

Machine Parameters

| モデル | MHK-1500EC |

|---|---|

| 最大シートサイズ | 1500×1100mm |

| 最小シートサイズ | 480×480mm |

| 最大切断サイズ | 1480×1080mm |

| Minimum Width of Double Cuts | 12mm |

| 最小グリッパーマージン | 6-12mm |

| Cutting Rule Height | 23.8mm |

| 内側チェイスサイズ | 1520×1130mm |

| 在庫範囲 | E, B, C, A and AB corrugated paper |

| 最大動作速度 | 6000s/h |

| 最大ダイカット力 | 400T |

| Mobile Lower Platen Adjusting Range | ±1.5mm |

| Max. Delivery Pile Height(Curtain type paper collection) | 1600mm (With wooden pallet) |

| Machine Dimensions(Curtain type paper collection) | 10490×5240×2800mm(L×W×H) (W: platform included) |

| Max. Delivery Pile Height(Stacking type paper collection) | Stacking type paper receiving (optional) |

| Machine Dimensions(Stacking type paper collection) | 11782×5240×2397mm(L×W×H)(W: platform included) |

| 機械の正味重量 | 23T |

| メインモーターのワット数 | 15kW |

| 全負荷電力 | 30kw |

| 空気要件 | 圧力: 0.6~0.7Mpa、流量: ≥0.37m3/分 |

| NOTE | Features that are the same in the table are written as one. |

レビュー

レビューはまだありません。