MHC 1100F/1300F/1500F/1650F/1900F 自動ダイカットおよび折り目付け機 (リードエッジフィーダー)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsAppチャット

Product Description

Introduction to the MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine (Lead Edge Feeder)

The MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine with Lead Edge Feeder is a cutting-edge solution designed to meet the high demands of the packaging and printing industries. Combining precision, efficiency, and advanced technology, this machine ensures superior performance and reliability, making it an essential asset for high-volume production environments.

主な特徴

高精度と正確性

The MHC F series delivers millimeter-perfect die cutting and creasing, making it ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and ensures superior product quality, essential for maintaining high production standards.

Lead Edge Feeder System

The integrated lead edge feeder system ensures accurate and consistent material feeding, significantly reducing the risk of misfeeds. This system enhances the overall reliability and efficiency of the production process, maintaining high-speed operations and smooth, continuous production.

高速パフォーマンス

Designed for high-speed operations, the MHC F series significantly boosts productivity. Its robust construction and advanced technology enable it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy or quality.

Advanced Automation

The MHC F series features comprehensive automation, including automatic feeding, die cutting, and creasing functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

ユーザーフレンドリーなインターフェース

An intuitive touch-screen display provides easy setup and real-time monitoring. This user-friendly interface minimizes the learning curve for operators, ensuring smooth and efficient operation.

利点

- 効率の向上: The combination of high-speed operations, lead edge feeder system, and advanced automation streamlines the workflow, reducing downtime and labor costs.

- 安全性の向上: Equipped with emergency stop buttons and protective guards, the MHC F series ensures a safe working environment, adhering to the highest industry standards.

- Versatility: Ideal for various applications, including packaging, labels, signage, and custom print materials. Its precision and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

アプリケーション

The MHC 1100F/1300F/1500F/1650F/1900F is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

業界への影響

By integrating the latest technology and automation, the MHC F series Automatic Die Cutting & Creasing Machine with Lead Edge Feeder sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

結論

The MHC 1100F/1300F/1500F/1650F/1900F Automatic Die Cutting & Creasing Machine with Lead Edge Feeder represents a significant advancement in die cutting and creasing technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the MHC F series means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

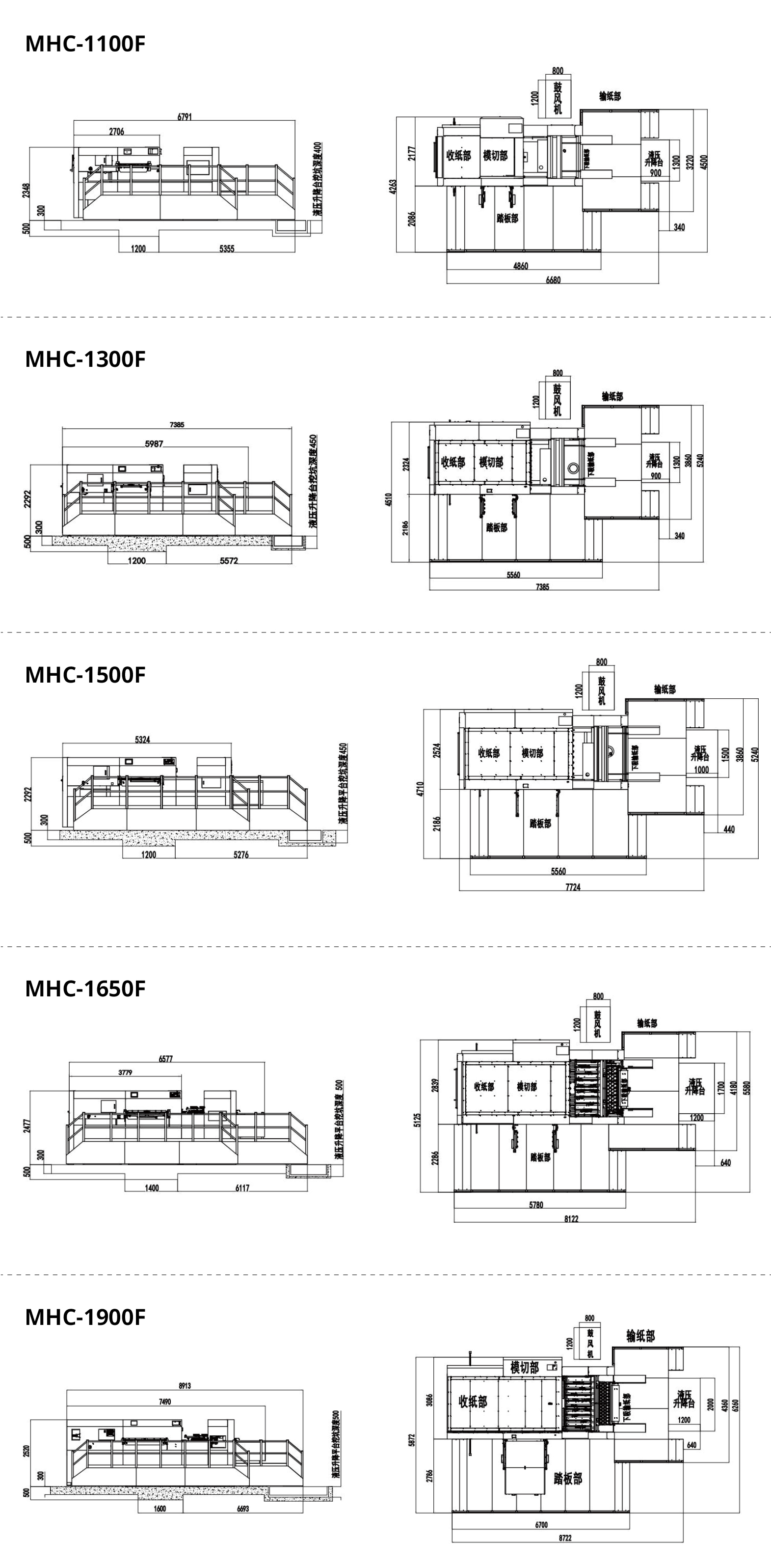

描画

Features Introduction

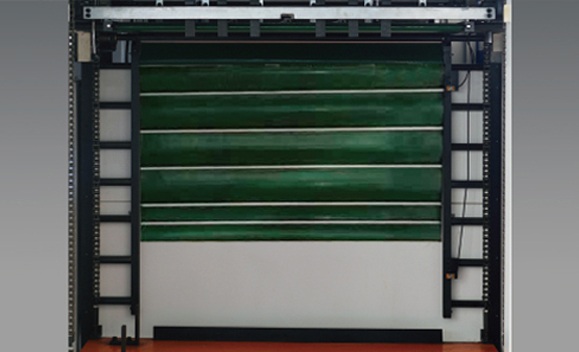

Lead edge feeder

Top gear and precise Lead Edge Feeder design, allowed consistent feeding with various quality corrugated board.

New technology polyurethane wheel surface with grid lifter and air cushion ensure smooth feeding and accurate alignment even warped board.

Fine vacuum suction adjustment through inverter adapts to wide range stock from f flute to double wall corrugate.

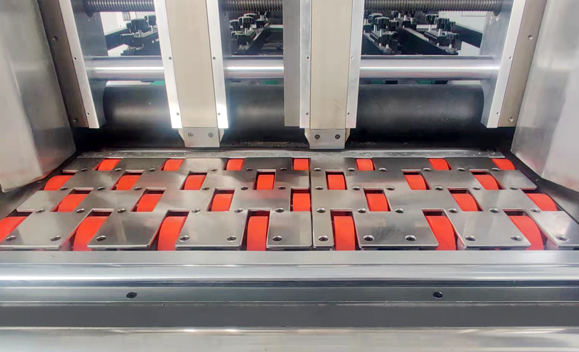

Sheet transmission and alignment section

Selectable left and right side push lays to ensure accurate alignment.

Advanced non-stop adjustment of feeding timing, reduce down time.

Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

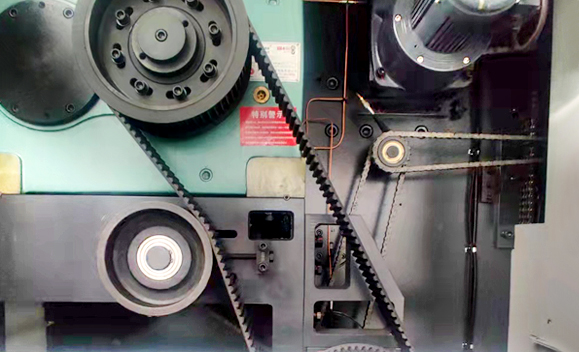

Timing belt driven device

台湾の高精度な間欠セグメンテーションにより、長期間の使用でも高い位置精度が保証されます。

● MHC1300/1500 series adopt timing belt driven system

● MHC1650/1900 series adopt chain driven system

Paper collecting unit

ノンストップカーテンによる自動搬送。このカーテンは搬送部に移動し、パイル交換中に到着した用紙をキャッチします。用紙収集用の 2 つのブロワーにより、薄い紙と厚い紙をきれいに収集できます。

自動潤滑システム

Adopt concentrated auto lubrication system to make sure the driven parts working better.

Machine Parameters

| モデル | MHC-1100F |

|---|---|

| Max. Sheet Size | 1100×790mm |

| Min. Sheet Size | 470×450mm |

| Max. Die Cutting Size | 1070×770mm |

| 最大動作速度 | 7000秒/時 |

| Min. Gripper Waste | 12mm |

| Min. Gripper Margin | 6-12mm |

| Cutting Rule Height | 23.8mm |

| Electrical Power | 380V, 50HZ, 3PH |

| Air Pump Displacement | Air compressor displacement 1.05m3/min,12kg/cm2–( prepared by user) |

| Min. Motor Power | 11kW |

| 最大作動圧力 | 300T |

| 機械重量 | 16T |

| 機械寸法 | 7000×4250×2350mm |

| 在庫範囲 | ≤7mmの段ボール紙、E、B、C、A、AB段ボール紙 |

| NOTE | Features that are the same in the table are written as one. |

レビュー

レビューはまだありません。