MHC 1060AR/1080AR Automatic Die Cutting Machine(Heavy duty, Heating system)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsAppチャット

Product Description

Introduction to the MHC 1060AR/1080AR Automatic Die Cutting Machine (Heavy Duty, Heating System)

The MHC 1060AR/1080AR Automatic Die Cutting Machine with Heating System (Heavy Duty) is an advanced solution designed to meet the rigorous demands of the packaging and printing industries. This high-performance machine combines precision, durability, and innovative heating technology to enhance the die cutting process, making it an indispensable asset for high-volume production environments.

主な特徴

高精度と正確性

The MHC 1060AR/1080AR ensures millimeter-perfect die cutting, ideal for applications that require detailed and exact specifications. This high level of precision reduces material waste and ensures superior product quality, essential for maintaining high production standards.

Heavy-Duty Performance

Built to withstand intensive use, the MHC 1060AR/1080AR is engineered with robust materials and advanced technology. Its durable construction guarantees long-term reliability and consistent performance, even under the most demanding production conditions.

Integrated Heating System

A standout feature of the MHC 1060AR/1080AR is its integrated heating system. This system enhances the die cutting process by ensuring smooth and clean cuts, particularly for materials that are challenging to process at room temperature. The heating system also improves creasing results, making it ideal for complex and high-precision tasks.

高速パフォーマンス

Designed for high-speed operations, the MHC 1060AR/1080AR significantly boosts productivity. Its advanced technology and robust construction enable it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy.

Advanced Automation

The MHC 1060AR/1080AR features comprehensive automation, including automatic feeding, die cutting, and heating functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

ユーザーフレンドリーなインターフェース

An intuitive touch-screen display provides easy setup and real-time monitoring. This user-friendly interface minimizes the learning curve for operators, ensuring smooth and efficient operation.

利点

- 効率の向上: The combination of high-speed operations, heating system, and advanced automation streamlines the workflow, reducing downtime and labor costs.

- 安全性の向上: Equipped with emergency stop buttons and protective guards, the MHC 1060AR/1080AR ensures a safe working environment, adhering to the highest industry standards.

- Versatility: Ideal for various applications, including packaging, labels, signage, and custom print materials. Its precision and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

アプリケーション

The MHC 1060AR/1080AR is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and integrated heating system make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

業界への影響

By integrating the latest technology and automation, the MHC 1060AR/1080AR Automatic Die Cutting Machine with Heating System sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

結論

The MHC 1060AR/1080AR Automatic Die Cutting Machine with Heating System (Heavy Duty) represents a significant advancement in die cutting technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the MHC 1060AR/1080AR means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

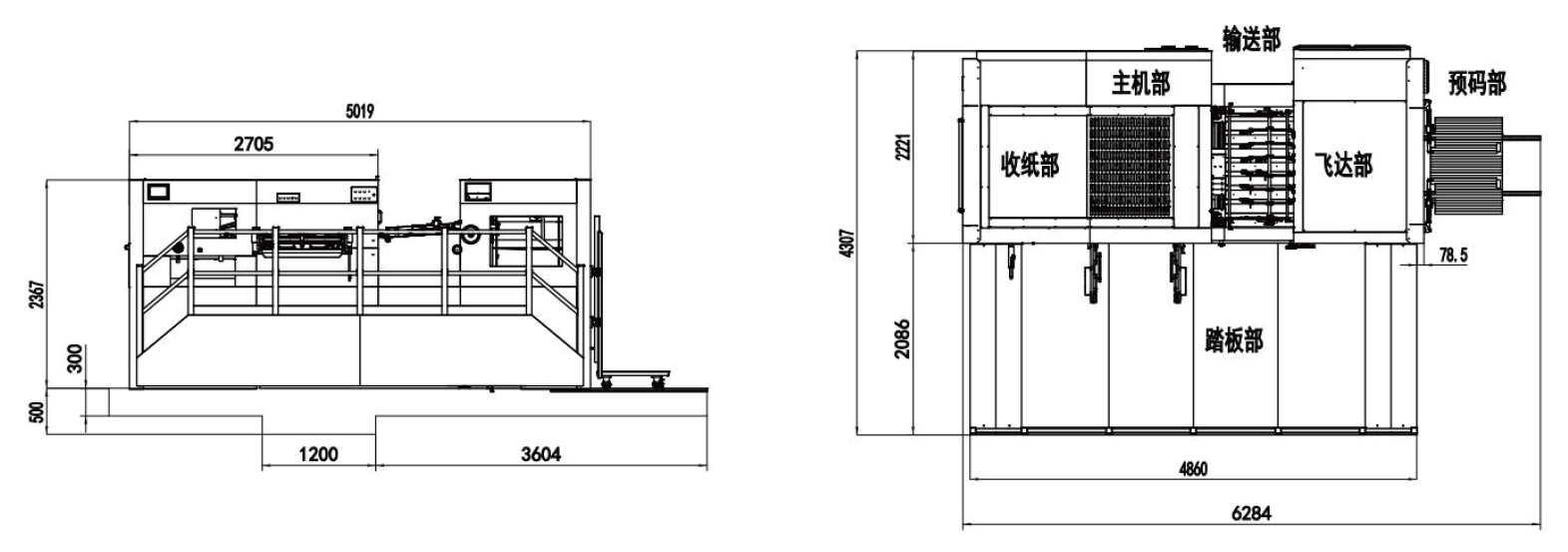

描画

部分的な紹介

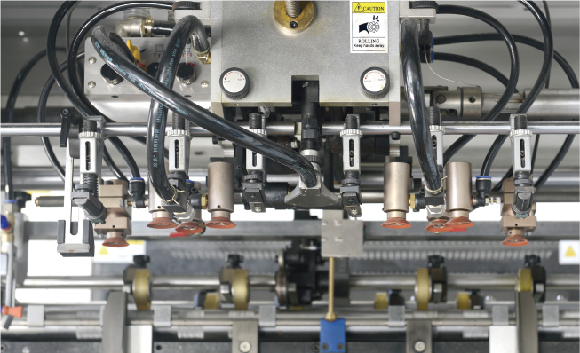

フィーダーユニット

Four pick up and four forward suck heads with angle adjustment to handle different kinds of materials.

給餌テーブル

生産時にシートの位置をフロントレイに手動で調整する同期装置、シート押さえ装置(シートをフロントレイにガイドする)。

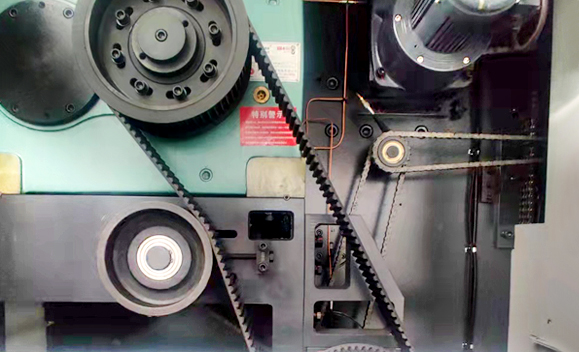

Timing belt driven device

台湾の高精度な間欠セグメンテーションにより、長期間の使用でも高い位置精度が保証されます。

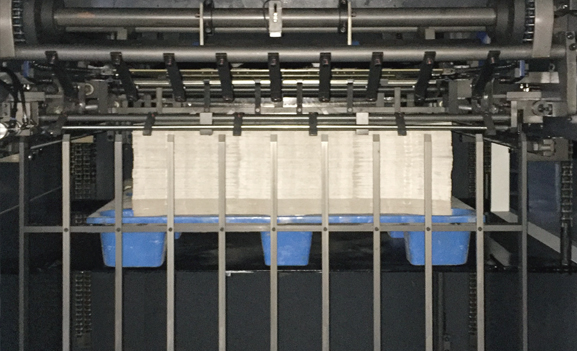

Paper collecting unit

ノンストップカーテンによる自動搬送。このカーテンは搬送部に移動し、パイル交換中に到着した用紙をキャッチします。用紙収集用の 2 つのブロワーにより、薄い紙と厚い紙をきれいに収集できます。

自動潤滑システム

Adopt concentrated auto lubrication system to make sure the driven parts working better.

Machine Parameters

| モデル | MHC-1060AR |

|---|---|

| 最大シートサイズ | 1060×760mm |

| 最小シートサイズ | 400×350mm |

| 最大切断サイズ | 1050×750mm |

| Max. Embossing Area | 1050×750mm |

| 最小グリッパーマージン | 9-17mm |

| 内側チェイスサイズ | 1100×790mm |

| 在庫範囲 | Paper: from 90 to 2000g/m2, 0.1~2mm, corrugated board: up to 4mm |

| ダイカット精度 | ≤±0.1mm |

| Embossing Accuracy | ≤±0.1mm |

| 最大ダイカット力 | 600T |

| 最大動作速度 | 7500s/h (Die cutting);7500s/h (Hot pressing) |

| Max. Feeder Pile Height | 1600mm (With wooden pallet) |

| Max. Delivery Pile Height | 1400mm (With wooden pallet) |

| Electric-heated System | 20 temperature ranges, 40-180℃ is adjustable |

| 機械寸法 | 6284×4307×2367mm(L×W×H) (L: paper prepared track included, W: platform included) |

| 機械の正味重量 | 18.5T |

| メインモーターのワット数 | 15kW |

| 全負荷電力 | 35kw |

| 空気要件 | 圧力: 0.6~0.7Mpa、流量: ≥0.37m3/分 |

| NOTE | Features that are the same in the table are written as one. |

レビュー

レビューはまだありません。