BHT 1060CE Automatic Die Cutting and Creasing Machine With Stripping

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsAppチャット

Product Description

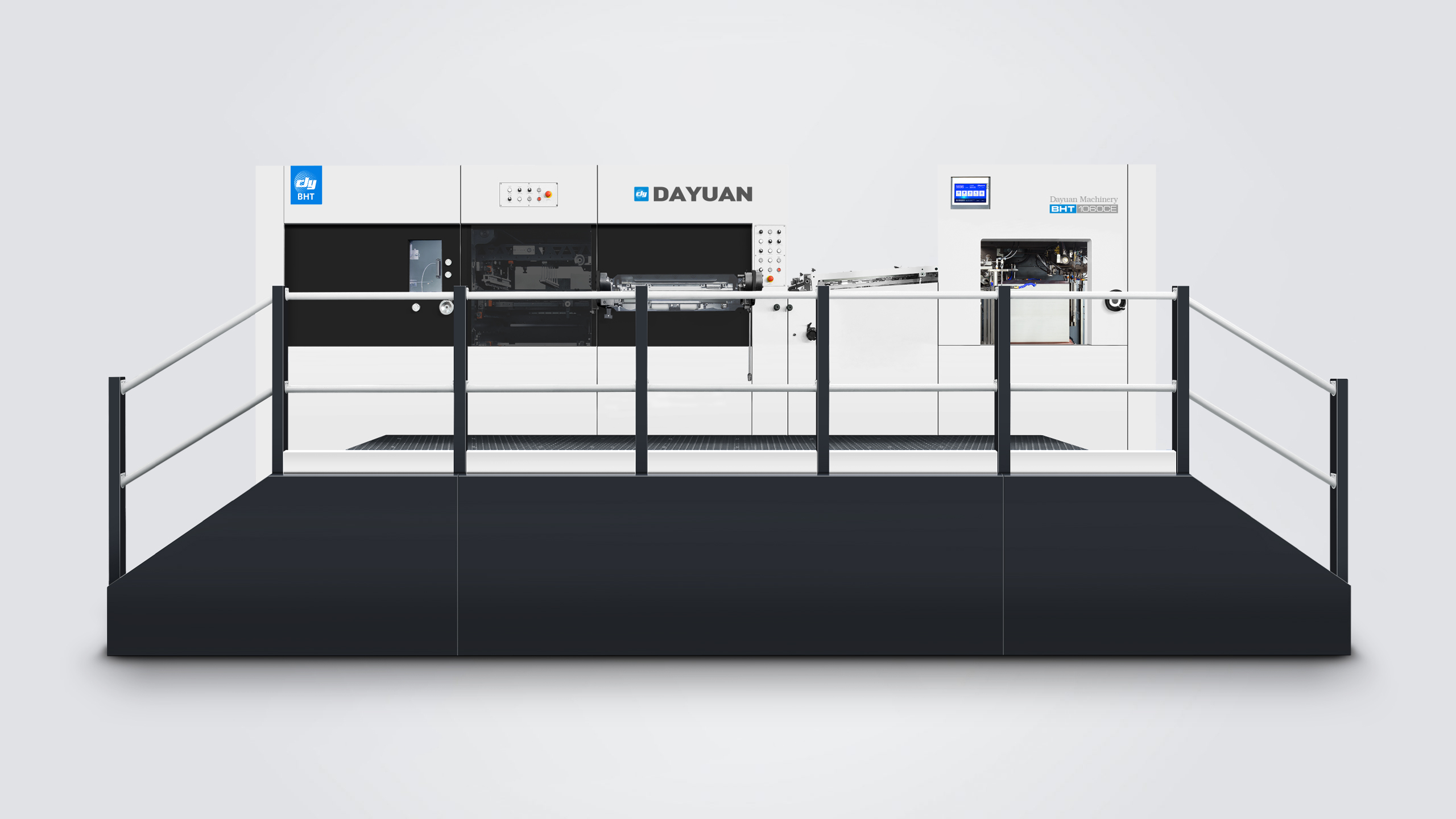

Introduction to the BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping

The BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping is an advanced solution designed for precision and efficiency in the packaging and printing industries. This machine integrates die cutting, creasing, and stripping functionalities into a single, streamlined system, making it an essential asset for modern manufacturing environments.

主な特徴

高精度と正確性

The BHT 1060CE ensures millimeter-perfect die cutting and creasing, ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and enhances overall product quality.

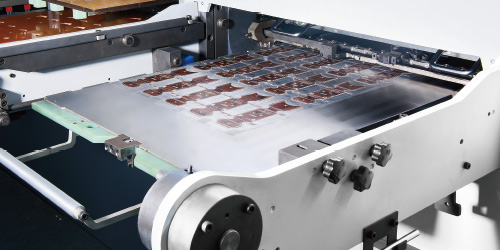

統合されたストリッピング機能

One of the standout features of the BHT 1060CE is its integrated stripping functionality. This system automatically removes waste material, ensuring clean and precise edges, reducing manual labor, and speeding up the production process.

高速パフォーマンス

Designed for high-speed operations, the BHT 1060CE significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising on accuracy.

利点

- 効率の向上: The automatic feeder and delivery system streamline the workflow from start to finish, reducing downtime and labor costs.

- ユーザーフレンドリーなインターフェース: 直感的なタッチスクリーン ディスプレイにより、セットアップが簡単になり、リアルタイムの監視が可能になり、オペレーターの学習曲線が最小限に抑えられ、スムーズな操作が保証されます。

- 安全機能: 緊急停止ボタンと保護ガードが装備されたこの機械は、業界最高水準に準拠した安全な作業環境を保証します。

アプリケーション

The BHT 1060CE is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and integrated stripping function make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

結論

The BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping sets a new standard in the industry with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, it helps businesses increase productivity while maintaining high quality and safety standards.

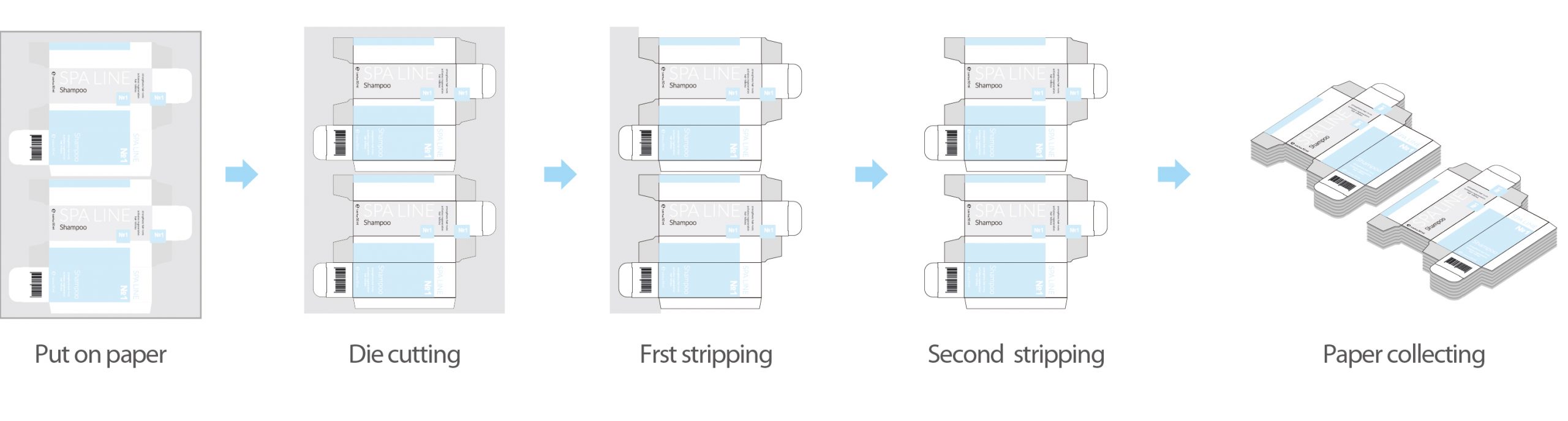

Process Flow

描画

部分的な紹介

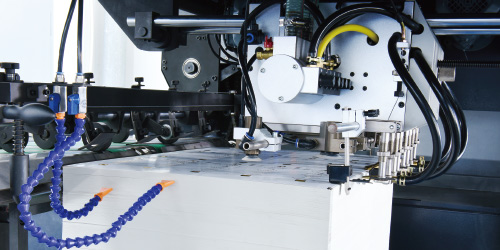

Feeder

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Double sheet detector

Ultrasonic double sheet detector without touching the paper, hence scratch free, reliable and quick set up.

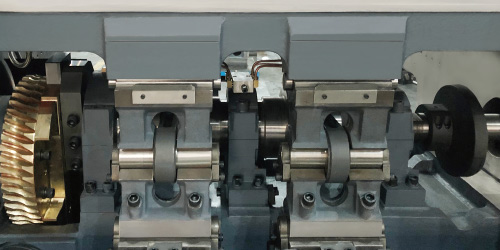

Gripper bar

7 gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

Variable speed worm gear drive device

Worm gear and toggle mechanism allows large motion angle hence minimum number and size of nicks at reasonable max. production speed.

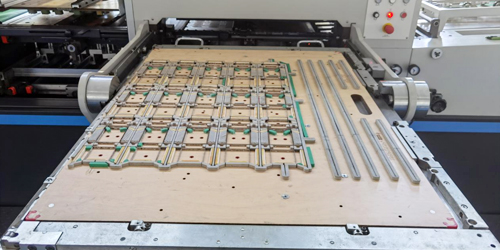

Plate setting

5mm hardened cutting plate or 4+1mm sandwich plate on top 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and easy make ready.

Mould quick locking device

Adopt center-line system and quick locking device to save make ready time.

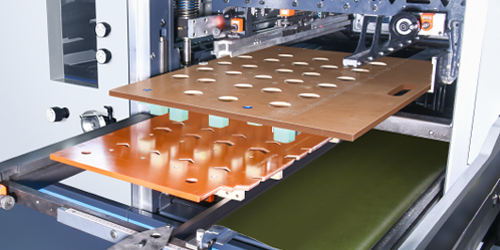

Advanced tooling lockup

Advanced quick tooling set up system ensures fast job change over and hence high productivity at both stripping stations.

Gripper edge waste removal device

Gripper edge stripping and removing system with conveyor belt to remove the gripper edge waste sideways to the drive side.

Auto non-stop collecting device

Main collecting device and Auto non-stop collecting device switch automatically without any operation, which make the machine more efficient.

Germany vaccum pump

ドイツ ベッカー社のオイルフリーブロワーと真空ポンプ。

自動潤滑システム

Adopt concentrated auto lubrication system to make sure the driven parts working better.

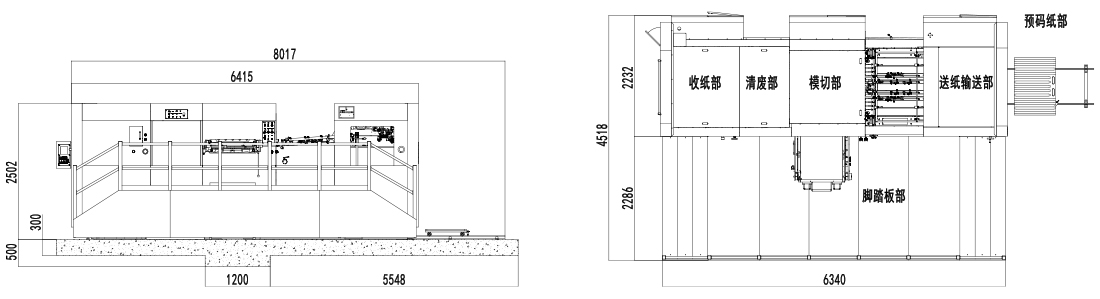

Machine Parameters

| モデル | BHT-1060CE |

|---|---|

| 最大シートサイズ | 1060×760mm |

| 最小シートサイズ | 400×350mm |

| 最大切断サイズ | 1060×745mm |

| Minimum Width of Double Cuts | 5mm |

| 最小グリッパーマージン | 9~17mm |

| Cutting Rule Height | 23.8mm |

| 内側チェイスサイズ | 1080×770mm |

| 在庫範囲 | 紙:80~2000g/m2、0.1~2mm、段ボール:最大4mm |

| ダイカット精度 | ≤±0.075mm |

| 最大ダイカット力 | 300T |

| 最大動作速度 | 9000s/h |

| 最大フィーダーパイル高さ | 1630mm(With wooden pallet) |

| 最大排出パイル高さ | 1480mm(With wooden pallet) |

| 機械寸法 | 8017×4518×2502mm (L×W×H) (L: paper prepared track included, W: platform included) |

| 機械の正味重量 | 18000kg |

| Main Motor Power | 15KW |

| Total Power Required | 23KW |

| 空気要件 | 圧力: 0.6~0.7Mpa、流量: ≥0.37m3/分 |

レビュー

レビューはまだありません。