Machine de découpe et de rainage automatique MHC 1300EFC/1500EFC/1650EFC avec dénudage (alimentation vers le bas)

(+86) 158 9968 3398 Discussion WhatsApp

Product Description

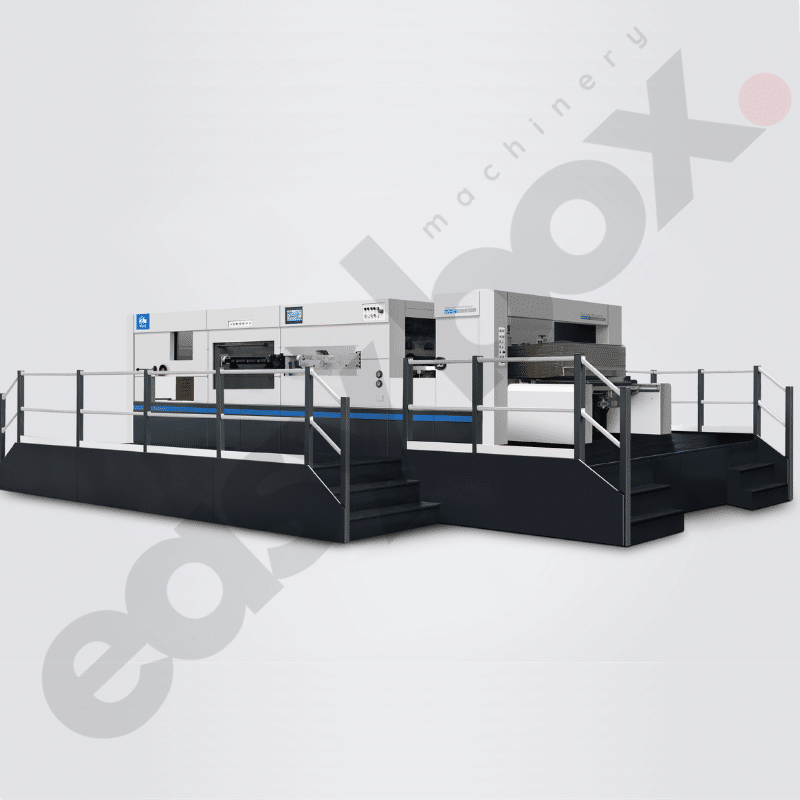

Introduction to the MHC 1300EFC/1500EFC/1650EFC Automatic Die Cutting and Creasing Machine with Stripping (Down Feeder)

The MHC 1300EFC/1500EFC/1650EFC Automatic Die Cutting and Creasing Machine with Stripping (Down Feeder) is a state-of-the-art solution designed to meet the high demands of the packaging and printing industries. This advanced machine integrates die cutting, creasing, and stripping functionalities with a down feeder system, ensuring superior performance, high productivity, and seamless integration in modern manufacturing environments.

Principales caractéristiques

Haute précision et exactitude

The MHC EFC series delivers millimeter-perfect die cutting and creasing, making it ideal for applications requiring detailed and exact specifications. This high level of precision reduces material waste and ensures superior product quality, which is essential for maintaining high production standards.

Système d'alimentation vers le bas

The integrated down feeder system ensures accurate and consistent material feeding, reducing the likelihood of misfeeds and enhancing overall reliability and efficiency. This system is crucial for maintaining high-speed operations and ensuring smooth, continuous production.

Fonction de dénudage intégrée

A standout feature of the MHC EFC series is its integrated stripping functionality. This system automatically removes waste material from the finished product, ensuring clean and precise edges. The stripping function reduces manual labor and speeds up the production process, leading to significant labor cost savings.

Performances à grande vitesse

Designed for high-speed operations, the MHC EFC series significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy.

Automatisation avancée

The MHC EFC series features comprehensive automation, including automatic feeding, die cutting, creasing, and stripping functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

Interface conviviale

Un écran tactile intuitif permet une configuration facile et une surveillance en temps réel. Cette interface conviviale minimise la courbe d’apprentissage des opérateurs, garantissant ainsi un fonctionnement fluide et efficace.

Avantages

- Efficacité améliorée : The combination of high-speed operations, down feeder system, and integrated stripping function streamlines the workflow, reducing downtime and labor costs.

- Sécurité améliorée : Equipped with emergency stop buttons and protective guards, the MHC EFC series ensures a safe working environment, adhering to the highest industry standards.

- Polyvalence: Idéal pour diverses applications, notamment l’emballage, les étiquettes, la signalisation et les matériaux d’impression personnalisés. Sa précision et son efficacité en font un atout précieux pour les entreprises cherchant à optimiser leurs processus de production et à répondre à des demandes élevées.

Applications

The MHC 1300EFC/1500EFC/1650EFC is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

Impact sur l'industrie

By integrating the latest technology and automation, the MHC 1300EFC/1500EFC/1650EFC Automatic Die Cutting and Creasing Machine with Stripping (Down Feeder) sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Conclusion

The MHC 1300EFC/1500EFC/1650EFC Automatic Die Cutting and Creasing Machine with Stripping (Down Feeder) represents a significant advancement in die cutting and creasing technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the MHC EFC series means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

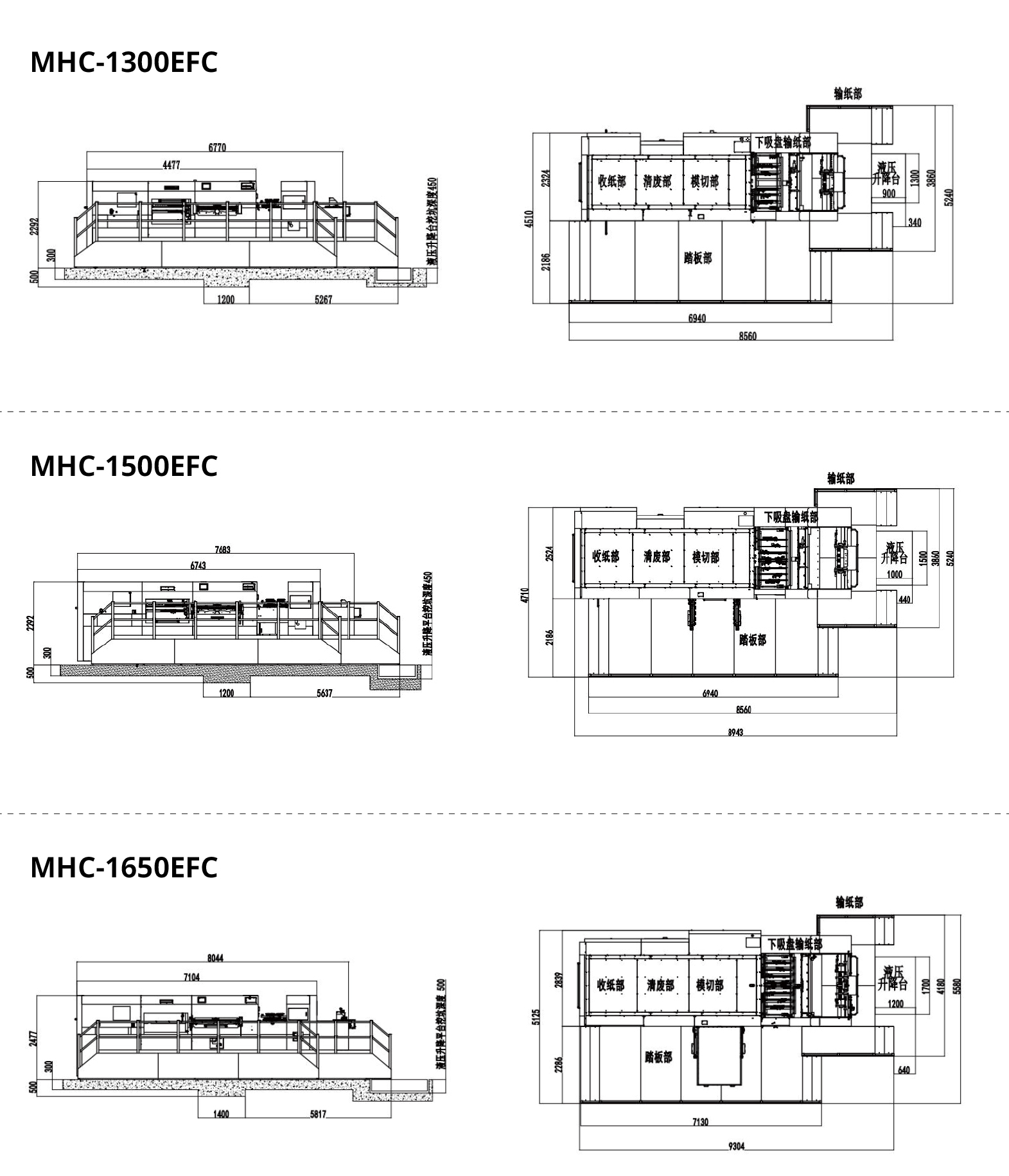

Dessin

Présentation des fonctionnalités

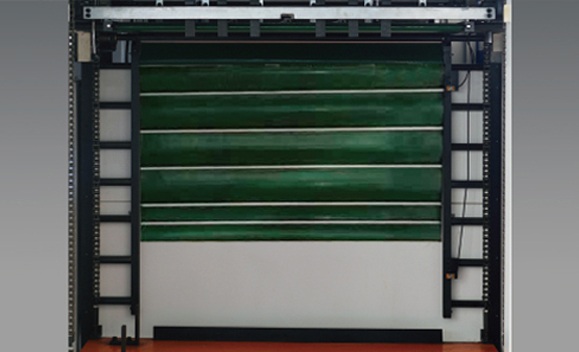

Lead edge feeder

Top gear and precise Lead Edge Feeder design, allowed consistent feeding with various quality corrugated board.

New technology polyurethane wheel surface with grid lifter and air cushion ensure smooth feeding and accurate alignment even warped board.

Fine vacuum suction adjustment through inverter adapts to wide range stock from f flute to double wall corrugate.

Sheet transmission and alignment section

Selectable left and right side push lays to ensure accurate alignment.

Advanced non-stop adjustment of feeding timing, reduce down time.

Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

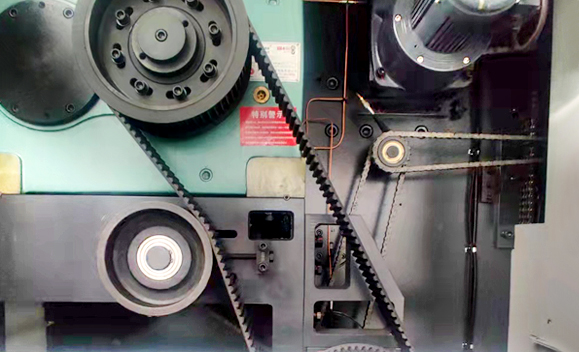

Dispositif entraîné par courroie de distribution

La segmentation intermittente de haute précision de Taiwan garantit une précision de positionnement élevée pour une utilisation de longue durée.

● Les séries MHC1300/1500 adoptent un système entraîné par courroie de distribution

● La série MHC1650 adopte un système entraîné par chaîne

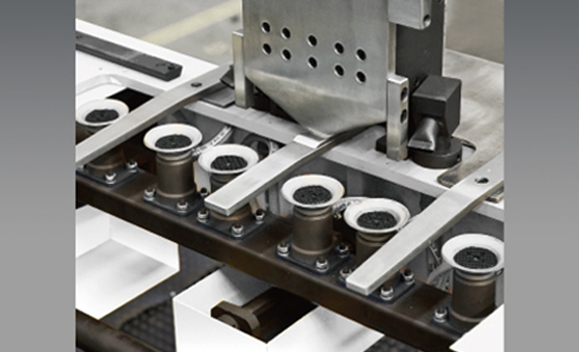

Unité de dénudage

Adoptez le système de ligne centrale, le cadre de montage de l'outil de dénudage supérieur et inférieur peut être retiré pour la configuration et la préparation du travail.

Auto Non-stop Collecting Device

● 1100 series equipped with manual non-stop collecting device

● 1300/1500/1650/1900 series equipped with auto non-stop collecting device

Système de lubrification automatique

Adoptez un système de lubrification automatique concentré pour garantir un meilleur fonctionnement des pièces entraînées.

Machine Parameters

| Modèle | MHC-1300EFC |

|---|---|

| Max. Sheet Size | 1290×940mm |

| Min. Sheet Size | 470×470mm |

| Max. Die Cutting Size | 1280×920mm |

| Max. Working Speed | 5000 s/h |

| Min. Gripper Waste | 12mm |

| Min. Gripper Margin | 6-12mm |

| Hauteur de la règle de coupe | 23,8 mm |

| Electrical Power | 380 V, 50 Hz, triphasé |

| Air Pump Displacement | Air compressor displacement 1.05m3/min,12kg/cm2– ( prepared by user) |

| Min. Motor Power | 11 kW |

| Max. Working Pressure | 300T |

| Poids de la machine | 19T |

| Dimensions de la machine | 8760×4510×2300mm |

| Gamme de stocks | ≤8.5mm corrugated paper,E, B, C, A and AB corrugated paper |

| NOTE | Les fonctionnalités identiques dans le tableau sont écrites comme une seule. |

Avis

Il n’y a pas encore d’avis.