Machine à laminer les cannelures automatique EBM 2100P/2150P/2200P

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat WhatsApp

Product Description

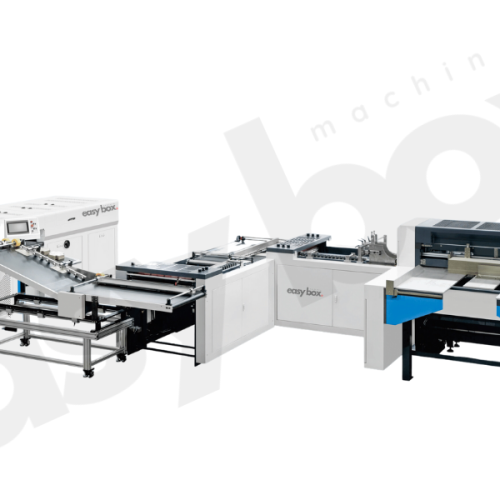

EBM 2100P/2150P/2200P Automatic Flute Laminating Machine: Revolutionizing the Packaging Industry

The Automatic Flute Laminating Machine is a breakthrough in the packaging sector, designed to automate the process of adhering printed paper sheets to corrugated cardboard layers. This state-of-the-art machinery enhances both the durability and aesthetic appeal of packaging materials, making it an indispensable tool for modern manufacturing lines.

Essential for Branding and Protection

An Automatic Flute Laminating Machine plays a critical role in creating visually appealing packaging that carries brand information and product details. By precisely laminating printed sheets onto corrugated cardboard, it ensures packages are not only strong but also carry essential branding and product details in an attractive format.

Features of Automatic Flute Laminating Machines

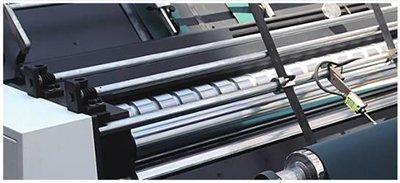

- Automated Feeding System: Ensures continuous production by automatically feeding paper and cardboard sheets into the machine.

- Precision Laminating and Aligning: Applies adhesive evenly and aligns printed paper with corrugated cardboard perfectly, enhancing the quality of the finished product.

- High Production Speeds: Ideal for large volume orders, these machines operate at high speeds to meet production demands efficiently.

- Versatility with Materials: Capable of processing various thicknesses and sizes of paper and cardboard, offering flexibility in packaging design.

Advantages in High-Quality Packaging Production

Using an Automatic Flute Laminating Machine accelerates production processes, reduces labor costs, and elevates brand visibility by creating eye-catching packaging. It’s particularly valuable for industries requiring high-quality packaging for electronic products, food items, consumer goods, and more, facilitating a significant improvement in packaging quality and production efficiency.

Conclusion

The introduction of Automatic Flute Laminating Machines into the packaging industry signifies a leap towards more efficient, high-quality packaging production. These machines not only streamline manufacturing processes but also play a vital role in enhancing the presentation and durability of packaged products. As the demand for aesthetically pleasing and sturdy packaging continues to rise, the Automatic Flute Laminating Machine stands out as a key component in meeting market needs, driving innovation and excellence in packaging design.

Machine Parameters

| Informations sur le produit | Fixed front gauge registration CHARACTERISTICS |

|---|---|

| Mécanisme d'alimentation de la feuille supérieure | High precision high speed automatic feeder, , feeding smoothly. |

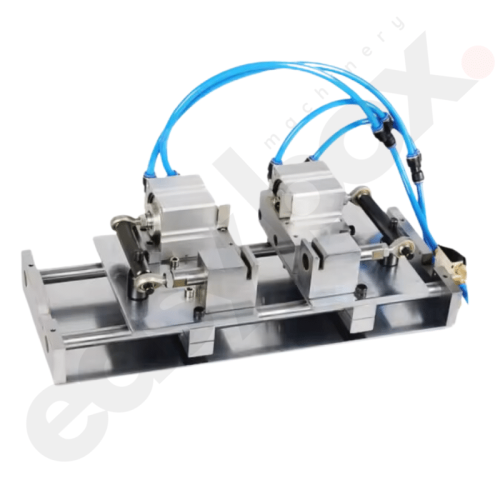

| Pressure Regulation Positioning | Single pressure regulation, to ensure that the two side pressure be same |

| Transmission | Floating design of press, no need to adjust the pressure |

| Système électrique | Main electrical components are imported brands |

| Pre-Stack Part | Standby stack table can pile paper under non-stop situation, along the rail into the elevator, high working efficiency. |

| Side Positioning (Option) | Side Gauge Positioning, error correction for about top paper stack and feeding process; |

| Nom du produit | Machine à laminer les cannelures automatique EBM 2100P/2150P/2200P |

| Modèle | EBM 2100P/2150P/2200P |

| Taille maximale de la feuille | 1300×1250mm / 1450×1250mm / 1650×1450mm |

| Taille minimale de la feuille | 400×400mm / 400×400mm / 400×400mm |

| Épaisseur de la feuille supérieure | 150-600g / 150-600g / 150-600g |

| Épaisseur de la feuille inférieure | A、B、C、E、F(Corrugated paper),(Industrial paperboard) |

| Max Speed | 6000Sheets/hour / 6000Sheets/hour / 6000Sheets/hour |

| Précision d'ajustement | ±1 mm / ±1 mm / ±1 mm |

| Dimensions de la machine | 11.5×2×2.4M / 11.5×2.2×2.4M / 11.5×2.4×2.4M |

| Poids de la machine | 5000kg / 5500kg / 6000kg |

| Puissance de la machine | 10KW/380V / 11KW/380V / 12KW/380V |

Avis

Il n’y a pas encore d’avis.