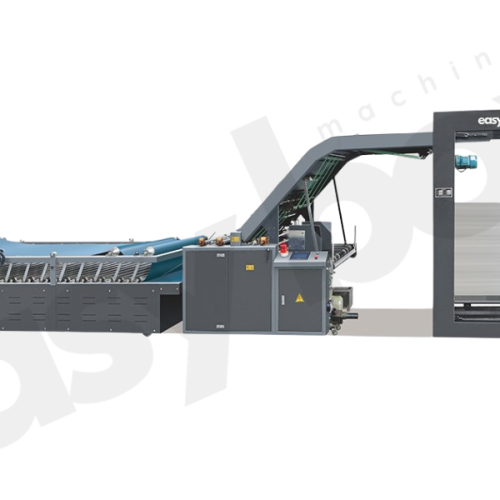

EBM 1307X/1310X Intelligent Cardboard Laminating Machine : The Future of the Packaging Industry

Today’s technological advancements are revolutionizing production processes at every level, with intelligent cardboard production machines leading the charge in transforming the packaging and printing industries. These smart machines, known for their high efficiency, precision, and flexibility, mark a turning point in the sector. This comprehensive article explores the features, benefits, and industry impact of intelligent cardboard production machines, shedding light on their significance.

What is an Intelligent Cardboard Production Machine?

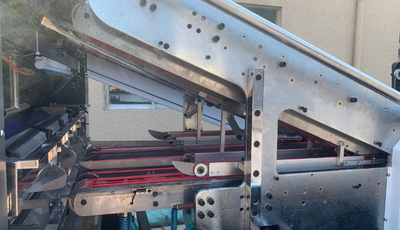

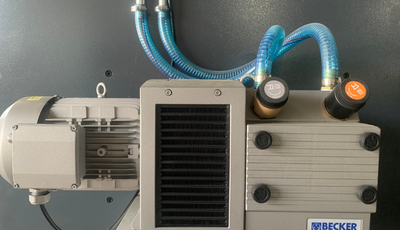

An intelligent cardboard production machine is an advanced piece of equipment that uses automated systems and cutting-edge technology to process, cut, and shape materials like cardboard and corrugated board. Equipped with sensors, artificial intelligence, and the Internet of Things (IoT) technologies, these machines streamline production processes to be more efficient and less prone to errors.

Principales caractéristiques et avantages

- Automation and Efficiency: Intelligent cardboard production machines reduce labor costs and speed up production processes through automated workflows.

- Précision et qualité : High-tech sensors ensure each product is manufactured to meet quality standards, improving overall product quality.

- Flexible Production: The ability to process various sizes and thicknesses of cardboard and corrugated board meets diverse packaging needs.

- Low Waste Ratio: Smart optimization algorithms maximize material use and minimize waste.

- User-Friendly Interfaces: Interfaces designed for ease of use shorten operator training times and simplify production processes.

Impact on the Industry

Intelligent cardboard production machines have become increasingly important, especially with the rise of e-commerce and the growing demand for packaging materials. These machines provide businesses with a competitive edge through their ability to produce customized packaging solutions. Additionally, the rising demand for sustainable production practices makes features like waste reduction and energy efficiency critical factors in choosing these machines.

Future Perspectives

With ongoing technological advancements, intelligent cardboard production machines are expected to evolve further and play an even larger role in the packaging industry. The integration of technologies like artificial intelligence and machine learning will automate and optimize production processes even more. This will lead to innovations that further reduce costs, increase production speed, and lessen environmental impact.

Conclusion

Intelligent cardboard production machines continue to revolutionize the packaging and printing industries. They offer businesses high efficiency, flexibility, and quality products while also contributing to sustainable production practices. In the future, the development of this technology is expected to support innovation and growth within the sector.

Avis

Il n’y a pas encore d’avis.