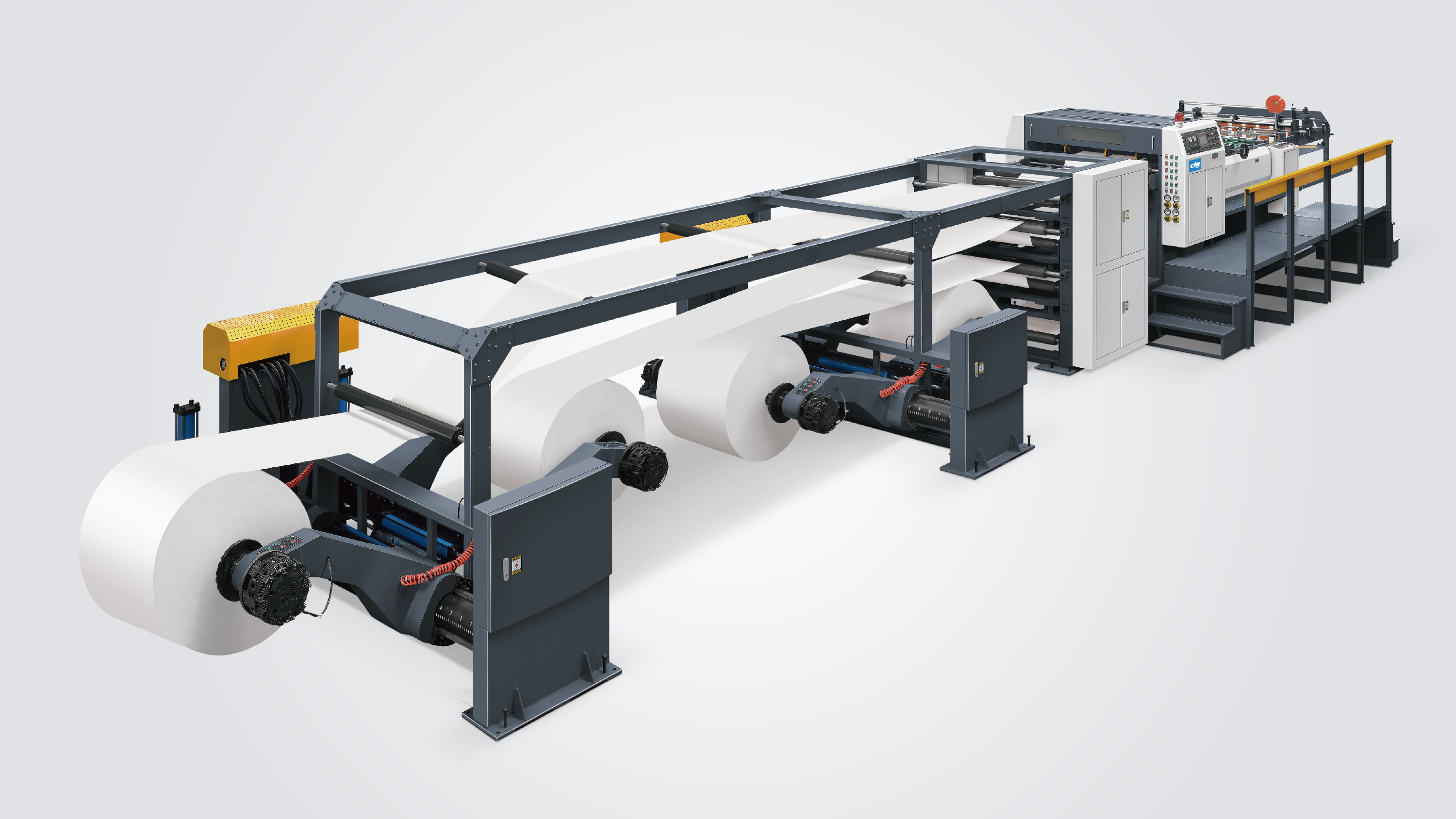

Coupe-feuilles haute vitesse de précision servo CM 1100A/1500A/1700A/1900A (quatre bobines)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat WhatsApp

Product Description

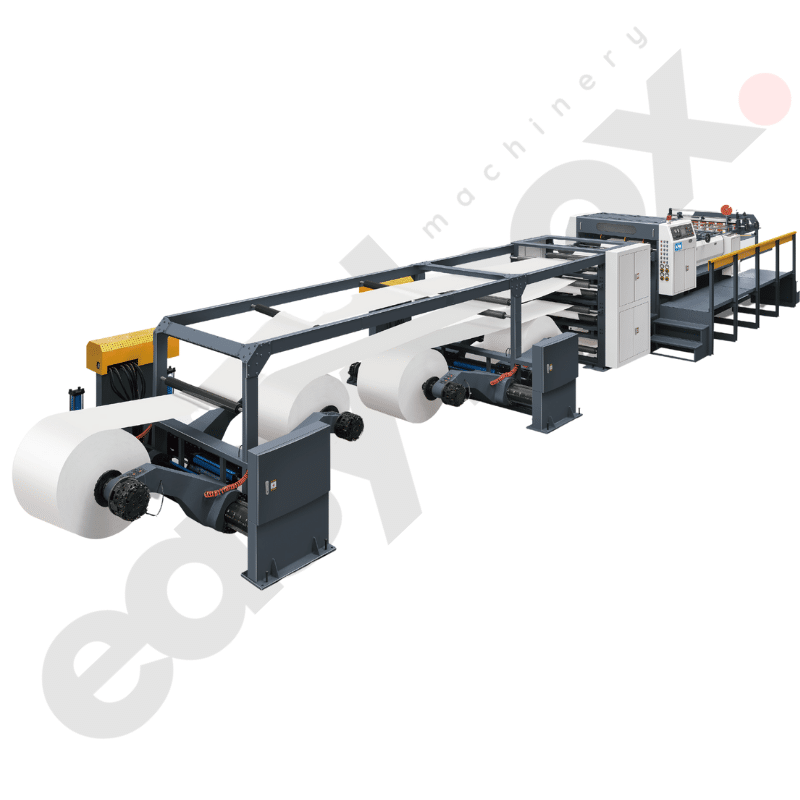

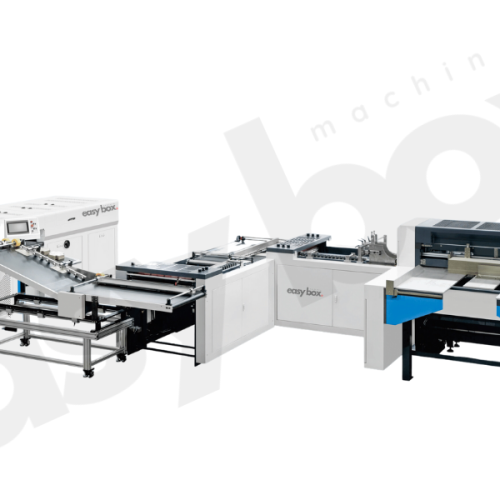

CM 1100A/1500A/1700A/1900A Servo Precision High Speed Sheet Cutter (Four Reels): Maximum Efficiency and Precision in Industrial Cutting

The CM 1100A/1500A/1700A/1900A Servo Precision High Speed Sheet Cutter (Four Reels) is engineered to meet the high demands of various industries requiring efficient and precise sheet cutting. With advanced servo technology and a four-reel configuration, these machines offer superior accuracy, speed, and reliability, making them an essential asset for any industrial cutting operation.

Principales caractéristiques et avantages

Technologie de précision servo avancée

The CM series machines are equipped with state-of-the-art servo motors, providing precise control over the cutting process. This advanced technology ensures high-speed operations with exceptional accuracy, making these machines ideal for industries that require meticulous precision.

Four Reel Configuration

The four-reel configuration significantly enhances material handling efficiency. This design allows for continuous operation by seamlessly switching between reels, minimizing downtime and maximizing productivity. The dual-reel system is particularly beneficial for high-volume cutting tasks.

High-Speed Operation

Designed for efficiency, the CM series machines deliver high-speed cutting performance, significantly increasing throughput. This capability is crucial for industries with large-scale cutting needs, ensuring timely completion of substantial orders without compromising quality.

Construction de haute qualité

Constructed from high-quality materials and featuring robust engineering, the CM series machines are built for durability and stability. This solid construction ensures that the machines can handle heavy-duty tasks efficiently and consistently, providing long-term reliable performance.

Structure de roue conique à quatre arbres

The four-shaft bevel wheel structure ensures steady operation, excellent cutting performance, and low noise levels. This design is particularly suited for various industrial environments where precision and reliability are paramount.

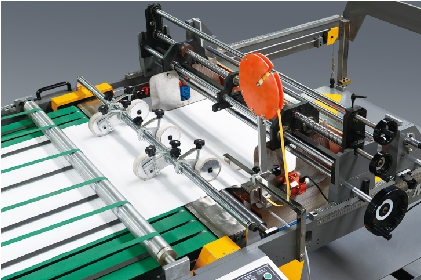

Système de refendage à positionnement automatique

The auto positioning slitting system is an advanced feature of the CM series. This system automatically adjusts the position of the slitting blades, ensuring consistent and accurate cuts every time. This automation reduces setup time and minimizes human error, leading to increased productivity.

Dispositif de pré-presse papier

The paper pre-press device ensures proper alignment and pressing of materials before cutting. This feature is essential for achieving high-quality cuts and preventing misalignment or errors during the cutting process.

Dispositif d'administration en trois temps (sans ligne d'impression)

Le dispositif de distribution en trois étapes élimine les lignes d'impression sur le produit fini, garantissant ainsi un aspect propre et professionnel. Cette fonctionnalité est particulièrement avantageuse pour les applications nécessitant des normes esthétiques élevées.

Dispositif de levage pneumatique pour panneau collecteur

Le dispositif de levage pneumatique du panneau collecteur améliore la facilité d'utilisation en permettant une collecte fluide et efficace des feuilles coupées. Ce mécanisme pneumatique réduit la manutention manuelle, augmentant ainsi le confort et la productivité de l'opérateur.

Applications dans diverses industries

The CM 1100A/1500A/1700A/1900A Servo Precision High Speed Sheet Cutter Machines are suitable for a wide range of industries. Their precision cutting capabilities make them ideal for:

- Impression: Assurer des coupes de haute qualité et précises pour les matériaux imprimés.

- Conditionnement: Assure une coupe précise et efficace des matériaux d'emballage.

- Produits en papier : Manipulation de différents types de feuilles de papier avec une grande précision.

- Impression commerciale : Améliorer la productivité et la qualité des opérations d’impression commerciale.

Progrès technologiques

The CM series stands out for its integration of advanced technological features, including servo precision and high-speed operation. These innovations streamline the cutting process, reduce downtime, and significantly increase output, making these machines a valuable asset for modern industrial operations.

Conclusion

The CM 1100A/1500A/1700A/1900A Servo Precision High Speed Sheet Cutter Machines with four-reel configuration offer an unparalleled combination of efficiency, precision, and advanced automation. Their robust construction, intelligent functions, and ease of operation make them an excellent investment for businesses looking to enhance their cutting operations. Whether for printing, packaging, or other paper products, the CM series machines deliver superior performance and reliability, meeting the high demands of today’s industrial environments.

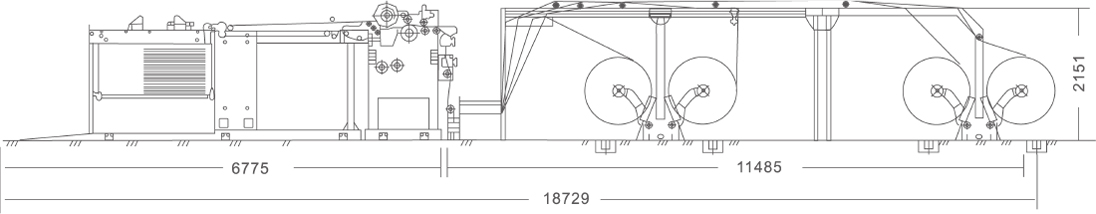

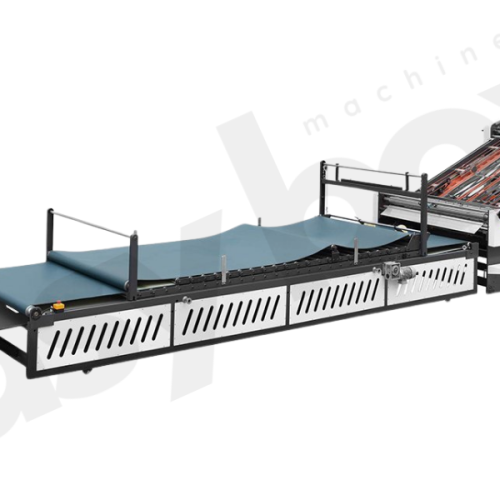

Dessin

Introduction partielle

Paper rack stand

Automatic anti-curve equipment

Automatic stacker

Machine Parameters

| Modèle | CM-1100A |

|---|---|

| Modèle de découpe de papier | The up knife cut reciprocally and the down knife is fixed |

| Épaisseur du papier de coupe | 60-550g |

| Diamètre max. de la volute | 1800mm |

| Largeur de coupe max. du papier | 1100mm |

| Plage de longueur de coupe | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm, Cutting length>1000mm: +/-0.1% |

| Vitesse de coupe max. | 300cuts/min |

| Vitesse de coupe max. | 300m/min |

| Hauteur max. d'empilage de papier | 1500mm |

| La demande de compresseur d'air | 0,8 Mpa |

| Consommation d'énergie | 380 V/220 V × 50 Hz |

| Gross weight | 9000kgs |

| Puissance à pleine charge | 22KW |

| NOTE | Les caractéristiques qui sont identiques dans le tableau sont écrites comme une seule. |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Avis

Il n’y a pas encore d’avis.