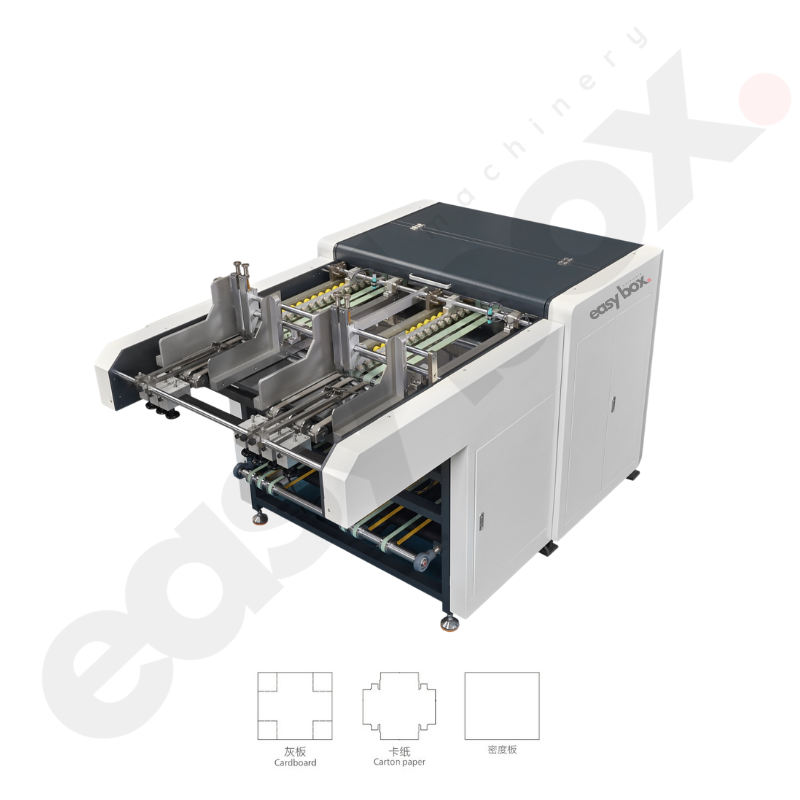

Machine à rainurer automatique pour cartons BTM-40A

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat WhatsApp

Product Description

Introducing the BTM-40A Automatic Carton Paper Grooving Machine: A Leap in Packaging Efficiency

In the fast-paced world of packaging, the Automatic Carton Paper Grooving Machine emerges as a game-changer, revolutionizing how businesses approach packaging production. Designed to automate the grooving process for carton paper, this innovative machinery ensures precision, efficiency, and consistency, qualities that are paramount in today’s competitive market. Its introduction marks a significant advancement in the packaging industry, streamlining operations and setting new standards for quality and speed.

Revolutionizing Carton Paper Processing

Le Automatic Carton Paper Grooving Machine is engineered for the seamless creation of grooves in carton paper, a critical step in producing foldable and structurally sound packaging. By automating this process, the machine eliminates the manual labor and variability associated with traditional grooving methods. Its state-of-the-art technology allows for rapid, accurate grooving, enabling manufacturers to meet the growing demand for high-quality, precise packaging solutions.

Key Benefits of the Automatic Carton Paper Grooving Machine

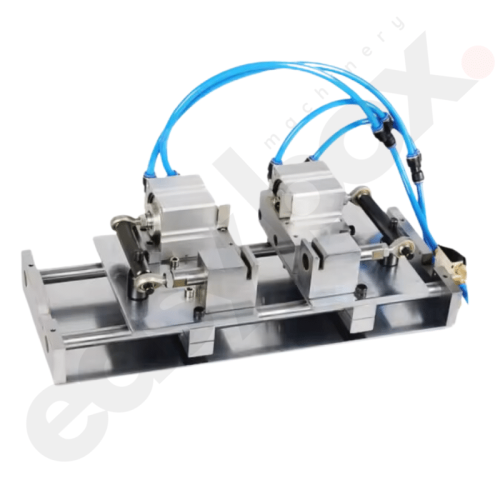

- Unmatched Precision: Automated controls and cutting-edge technology ensure that each groove is perfectly aligned and executed, resulting in superior fold lines and a flawless finish.

- Productivité améliorée : The machine’s high-speed operation significantly boosts production rates, allowing businesses to scale up their output without sacrificing quality.

- Efficacité opérationnelle : Streamlining the grooving process reduces the need for extensive manual intervention, freeing up resources and reducing production costs.

- Flexibilité et polyvalence : With adjustable settings and the ability to handle various carton paper sizes and thicknesses, the machine caters to a wide range of packaging designs and applications.

Transforming the Packaging Industry Landscape

Le Automatic Carton Paper Grooving Machine plays a pivotal role in transforming the packaging industry. By enabling rapid and precise production of carton paper packaging, it supports the development of innovative and environmentally friendly packaging solutions. Its efficiency and precision contribute to waste reduction, optimizing the use of materials and promoting sustainability in packaging operations.

Conclusion

Le Automatic Carton Paper Grooving Machine stands at the forefront of packaging technology, offering businesses a powerful tool to enhance their packaging quality and production efficiency. Its impact on the packaging industry is profound, driving advancements in packaging design, sustainability, and operational excellence. As businesses continue to seek ways to improve their packaging solutions, the reliance on such innovative machinery will undoubtedly increase, heralding a new era of efficiency and quality in packaging production.

Machine Parameters

| Nom du produit | Machine à rainurer automatique pour cartons BTM-40A |

|---|---|

| Modèle | BTM-40A |

| Quantité de rainures à la fois | 8/Emplacements |

| Vitesse de travail | 15-35 m/min |

| Taille maximale | 1000*600mm |

| Taille minimale | 160*140mm |

| Épaisseur du papier cartonné | 220-600g/m2 |

| Épaisseur du carton | 0.8-3.5mm |

| Puissance du moteur | 1.5KW/380V 3 Phase |

| Dimensions de la machine | L2200*W1560*H1380mm |

| Poids de la machine | 1300KG |

Avis

Il n’y a pas encore d’avis.