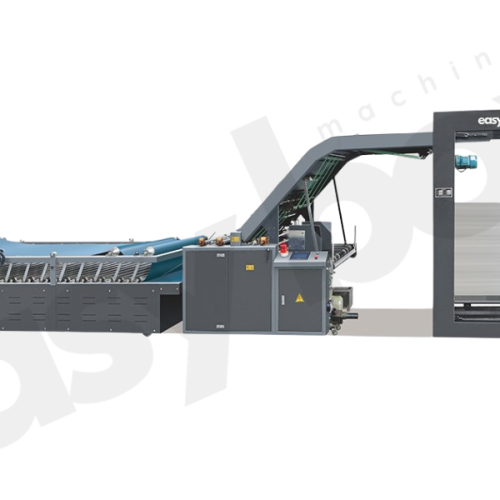

Máquina troqueladora y plegadora automática BHT 1650FC/1900FC/2100FC con alimentador de borde de entrada

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 Chat de WhatsApp

Product Description

Introduction to the BHT 1650FC/1900FC/2100FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder)

The BHT 1650FC/1900FC/2100FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder) is a cutting-edge solution designed for high precision and efficiency in the packaging and printing industries. This machine combines die cutting, creasing, and stripping functionalities with a lead edge feeder, ensuring superior performance and productivity.

Key Features

High Precision and Accuracy

The BHT 1650FC/1900FC/2100FC series delivers millimeter-perfect die cutting and creasing, making it ideal for applications that require detailed and exact specifications. This precision reduces material waste and enhances overall product quality.

Lead Edge Feeder

The integrated lead edge feeder ensures accurate and consistent feeding of materials, which is crucial for maintaining high-speed operations and reducing misfeeds. This feature enhances the efficiency and reliability of the production process.

Integrated Stripping Function

The machine’s stripping function automatically removes waste material from the finished product, ensuring clean and precise edges. This reduces the need for manual labor and accelerates the production process, leading to significant labor cost savings.

High-Speed Performance

Designed for high-speed operations, the BHT 1650FC/1900FC/2100FC series significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy.

Benefits

- Enhanced Efficiency: The combination of high-speed performance and integrated stripping function streamlines the workflow, reducing downtime and labor costs.

- Interfaz fácil de usar: An intuitive touch-screen display provides easy setup and real-time monitoring, minimizing the learning curve for operators and ensuring smooth operation.

- Safety Features: Equipped with emergency stop buttons and protective guards, the machine ensures a safe working environment, adhering to the highest industry standards.

Applications

The BHT 1650FC/1900FC/2100FC series is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and integrated stripping function make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

Conclusión

The BHT 1650FC/1900FC/2100FC Automatic Die Cutting & Creasing Machine with Stripping (Lead Edge Feeder) sets a new standard in the industry with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, it helps businesses increase productivity while maintaining high quality and safety standards.

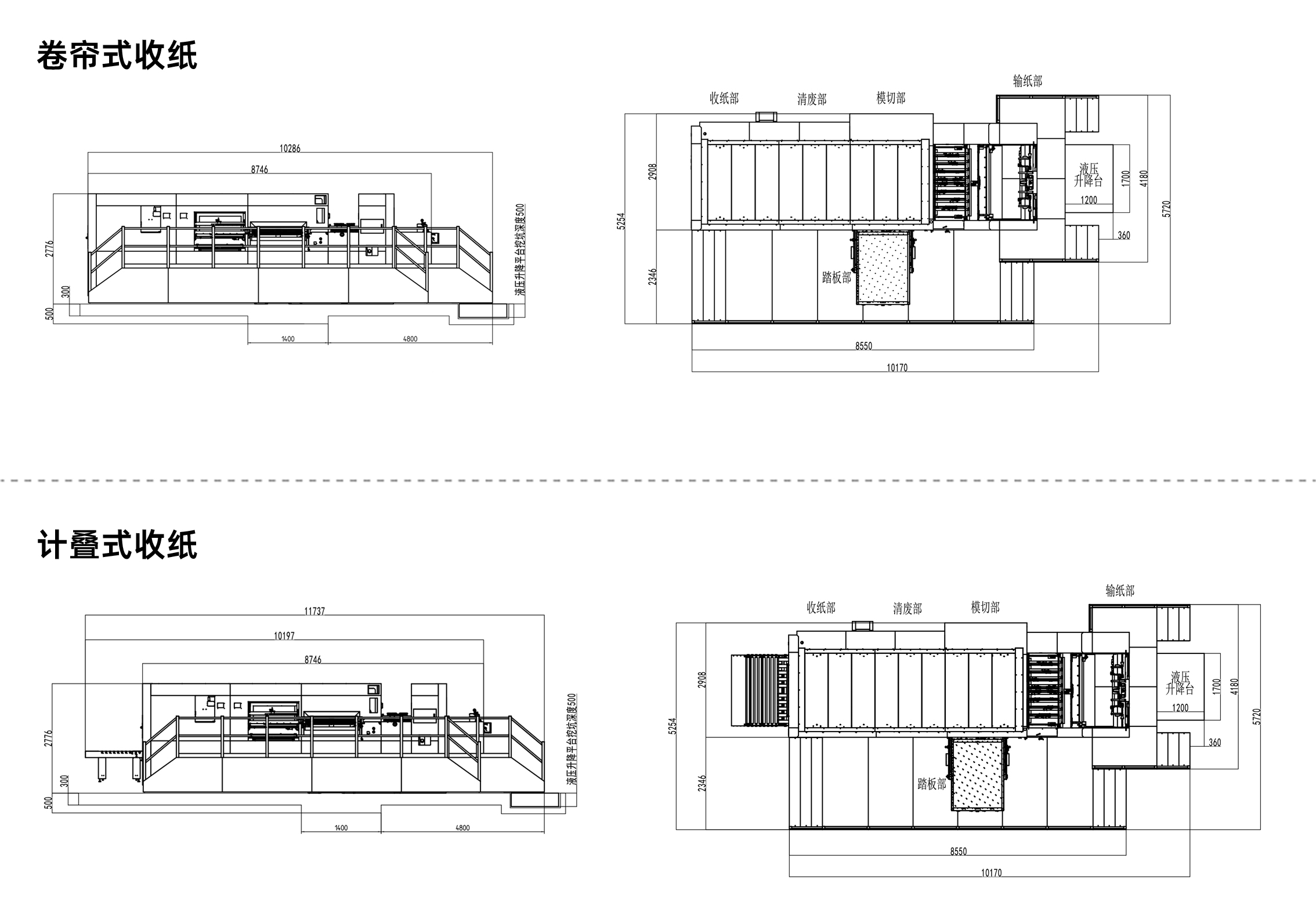

Dibujo

Features Introduced

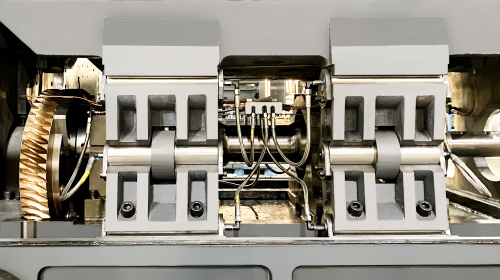

Lead edge feeder

Top gear and precise Lead Edge Feeder design, allowed consistent feeding with various quality corrugated board.

New technology polyurethane wheel surface with grid lifter and air cushion ensure smooth feeding and accurate alignment even warped board.

Fine vacuum suction adjustment through inverter adapts to wide range stock from F flute to double wall corrugate.

Sheet transmission and alignment section

Selectable left and right side push lays to ensure accurate alignment.

Advanced non-stop adjustment of feeding timing, reduce down time.

Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

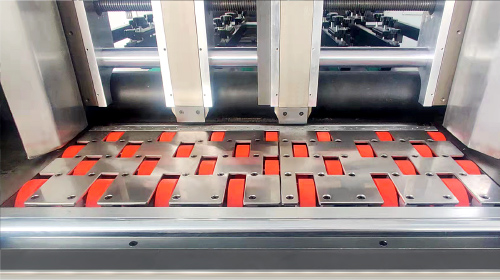

Variable speed worm gear drive device

Worm gear and toggle mechanism allows large motion angle hence minimum number and size of nicks at reasonable max. production speed.

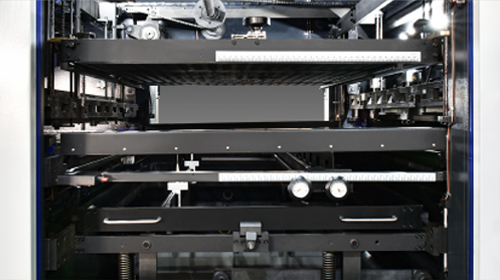

Three layer stripping section

Stationary middle stripping board, coupled with zero jerk, smooth upper frame motion curve with extra punch at the moment of impact to obtain cleaner waste removal.

Gripper bar register block at outlets of Stripping Station ensures the accuracy of stripping.

Center line system for quick stripping tool set up and change over, compatible with centerline.

Front edge waste removal system removes and transfers waste edge outside the machine via conveyor belt.

Paper counting & collecting section (Optional)

Escalator delivery fork cooperate with non-stop air cylinder for neat and positive conveying to belt table. Bundle Delivery table is ready for further connection with Breaker for inline operation (to be required at order).

Electrical batch counter as standard.

Spring loaded adjustable chain tensioner for maintaining constant tension thus reducing stress on chains and producing smooth gripper bar movement.

Auto non-stop collecting device (Optional)

Main collecting device and Auto non-stop collecting device switch automatically without any operation, which make the machine more efficient.

Machine Parameters

| Modelo | BHT-1650FC |

|---|---|

| Max. Sheet Size | 1650×1200mm |

| Min. Sheet Size | 650×500mm |

| Max. Die Cutting Size | 1630×1180mm |

| Minimum Width of Double Cuts | 10-18mm |

| Gripper Margin | 6-12mm |

| Cutting Rule Height | 23.8mm |

| Inner Chase Size | 1670×1230mm |

| Stock Range | ≤9mm corrugated paper, F, E, B, C, A and AB corrugated paper |

| Max. Die Cutting Speed | 6000s/h |

| Max. Die Cutting Force | 400T |

| Mobile Lower Platen Adjusting Range | ±1.5mm |

| Max. Delivery Pile Height | Stacking paper collection (optional) |

| Overall Dimension (L×W×H) | 11638×5254×2776mm |

| Net Weight Approx | 40T |

| Main Motor Wattage | 18.5kw |

| Full Load Wattage | 38kw |

| Air Requirement | Air pressure: 0.6~0.7Mpa, Flow rate: ≥1m3/min |

| NOTA | Las características que son iguales en la tabla se escriben como una sola. |

Valoraciones

No hay valoraciones aún.