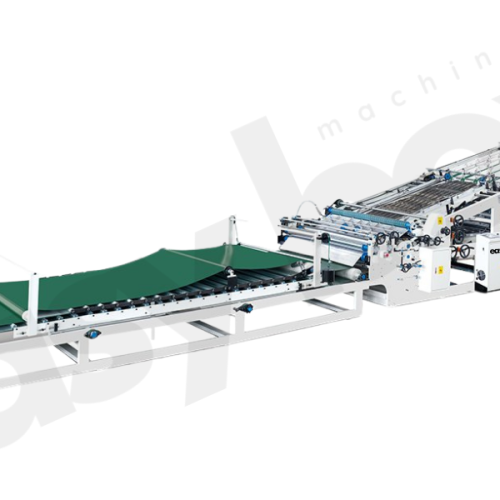

TYMB-930/1040/1100/1200 CE Hot Stamping And Cutting Machine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Product Description

TYMB-930/1040/1100/1200 CE Hot Stamping & Cutting Machine: Precision and Versatility in Printing

The TYMB-930/1040/1100/1200 CE series Hot Stamping & Cutting Machine is a next-generation machine designed for precision and efficiency in the printing industry. Known for its clockwork precision and impressive results, this machine is ideal for gilding-printing with colored electro-chemical aluminum, creating concave-convex die-cut pictures, trademarks, advertisements, sample boxes, book covers, and New Year cards. It serves as an essential tool for industries including printing, packaging, decoration, and plastics, working seamlessly with materials such as paper, cardboard, plastic, and leather.

Hauptfunktionen und Vorteile

Hochwertige Konstruktion

The TYMB series is built with high-quality materials and high-tension casting, ensuring durability and stability. This robust construction allows the machine to handle heavy-duty tasks efficiently while maintaining consistent performance.

Vier-Wellen-Kegelrad-Struktur

A standout feature of the TYMB series is its four-shaft bevel wheel structure. This design ensures steady operation, superior cutting performance, and low noise levels, making these machines suitable for various industrial environments.

Advanced Clutch System

Equipped with an air brake clutch, the TYMB series machines offer exceptional flexibility, reliability, and safety. The clutch system guarantees smooth operation and precise control, enhancing the overall efficiency of the stamping and cutting processes.

High-Strength Connecting Rod

The connecting rod in the TYMB series machines is made from 45# carbon steel, known for its high strength and durability. This component ensures the machine can handle tough materials while maintaining high cutting precision.

Ergonomic and Precise Design

The machine’s design focuses on ergonomic and precise operation. The layout of the machine’s height and gear angle is optimized for user comfort and efficiency. Additionally, the micro-adjusting gear device allows for fine-tuning, providing high precision in every cut.

Compliance with IEC Standards

Safety and compliance are top priorities for the TYMB series machines. The electrical system is designed according to IEC standards, ensuring safe operation and compatibility with global industrial environments.

Versatile Cutting Functions

The TYMB series machines offer three cutting functions: single slitting, successive slitting, and time delay. These adjustable functions allow users to tailor the machine’s performance to specific cutting tasks and material requirements.

Reliable Safety Protection

The machines include a robust safety protection system, ensuring that operators can work with confidence and peace of mind.

Concentrated Lubricating System

To maintain optimal performance and extend the machine’s lifespan, the TYMB series features a concentrated lubricating system. This system ensures that all moving parts are adequately lubricated, reducing wear and tear and minimizing maintenance requirements.

Anwendungen in verschiedenen Branchen

The TYMB-930/1040/1100/1200 CE Hot Stamping & Cutting Machines are suitable for a wide range of industries. Their precision and versatility make them ideal for:

- Drucken: Ensuring high-quality finishes on printed materials.

- Verpackung: Providing precise cuts and gilding for various packaging materials.

- Decoration: Creating intricate designs and decorative elements.

- Plastics: Handling different types of plastic sheets with ease.

- Leather Goods: Working with leather to create high-quality products.

Abschluss

The TYMB-930/1040/1100/1200 CE Hot Stamping & Cutting Machines offer a versatile and reliable solution for industries requiring precision stamping and cutting of various materials. Their advanced features, robust construction, and compliance with international standards make them an excellent investment for businesses looking to enhance their printing operations. Whether for single slitting or more complex stamping tasks, these machines deliver exceptional results with efficiency and safety.

Machine Parameters

| Modell | TYMB750 |

|---|---|

| Max. Platen Working Area | 750×520mm |

| Max. Gilding Printing Area | 740×510mm |

| Skip Order Range | Built-in Proessing With Computer |

| Working Pressure | 100T |

| Foil-delivered Length | 500mm |

| Foil-delivered Group | 2groups |

| Working Speed/Main Motor | 1380Time/h 2.2kw |

| Overall Power | 10kw |

| Overall Dimensions | 2150×1400×1900mm |

| Total Weight | 2500kg |

Bewertungen

Es gibt noch keine Bewertungen.