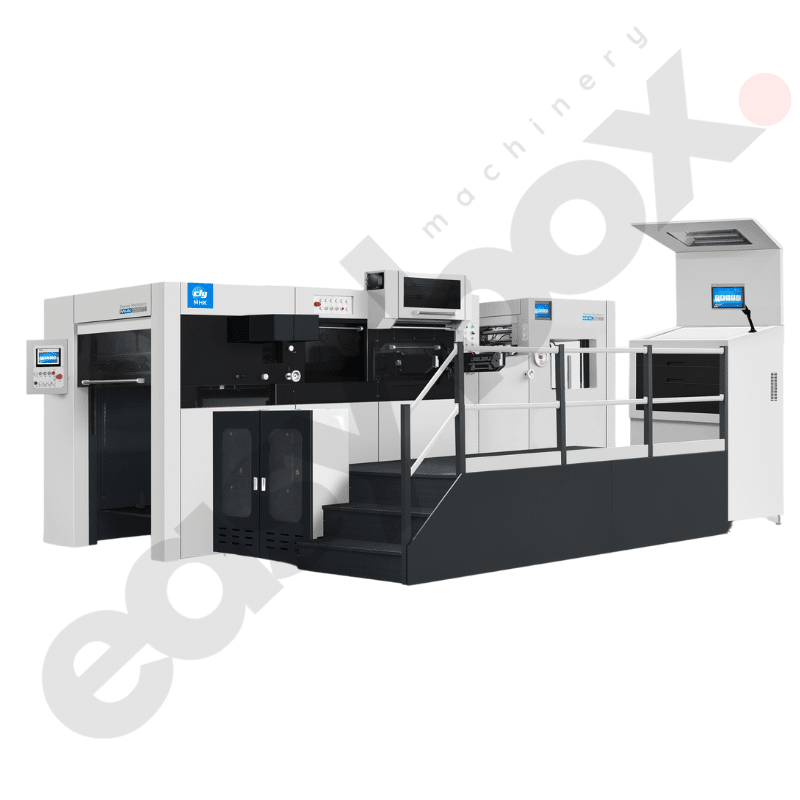

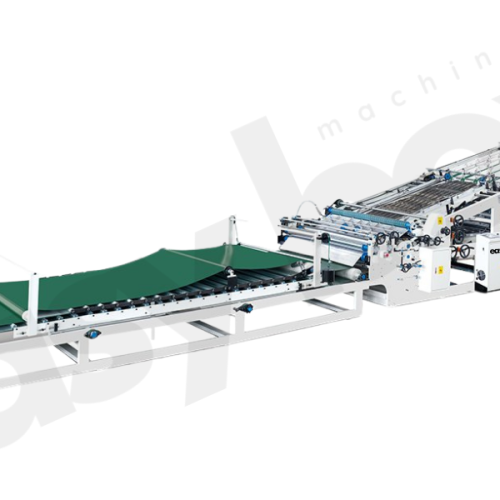

MHK 820T Automatische Heißfolienpräge- und Stanzmaschine

(+86) 158 9968 3398 WhatsApp-Chat

Product Description

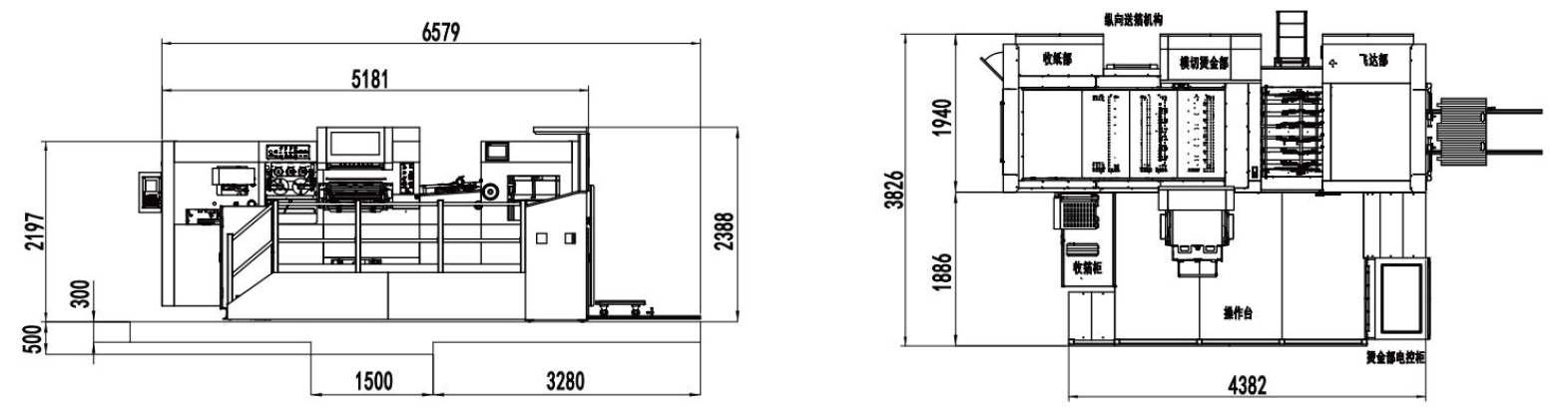

Zeichnung

MHK 820T Automatic Hot Foil Stamping & Die Cutting Machine: Precision and Efficiency for Modern Manufacturing

The MHK 820T Automatic Hot Foil Stamping & Die Cutting Machine is a state-of-the-art solution designed to meet the exacting demands of contemporary manufacturing. Combining advanced hot foil stamping with precise die cutting, this machine offers exceptional efficiency, accuracy, and reliability.

Hauptfunktionen und Vorteile

Advanced Hot Foil Stamping System

The MHK 820T features an advanced hot foil stamping system that allows for intricate and high-quality foil designs on various materials. This capability enhances the visual appeal of products, making it ideal for luxury packaging, high-end labels, and decorative items.

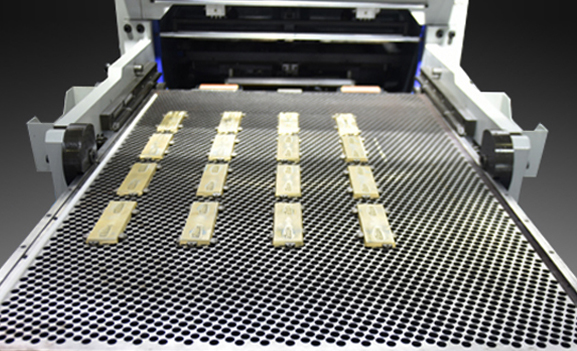

Precision Die Cutting

With its advanced die-cutting capabilities, the MHK 820T ensures clean and precise cuts every time. This precision is crucial for applications that demand detailed and flawless finishes, such as printing, packaging, and decorative industries.

Hochgeschwindigkeitsbetrieb

Designed for high-speed performance, the MHK 820T significantly increases production throughput. This capability is essential for large-scale production environments, ensuring the timely completion of substantial orders without compromising on quality.

Robust Construction

Constructed from high-quality materials, the MHK 820T is built for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

Benutzerfreundliches Bedienfeld

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Safety Features

Safety is a top priority with the MHK 820T. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Versatile Applications

The MHK 820T is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Drucken: Delivering high-quality stamping and cutting for printed materials.

- Verpackung: Providing precise die-cutting and foil stamping for packaging materials.

- Labels and Tags: Creating detailed and attractive designs for labels and tags.

- Decorative Applications: Enhancing decorative items with intricate cuts and foil accents.

Verbesserte Produktivität

The integration of high-speed operation, hot foil stamping, and die cutting functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Technologische Fortschritte

The MHK 820T stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Abschluss

The MHK 820T Automatic Hot Foil Stamping & Die Cutting Machine offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the MHK 820T delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Teilweise Einführung

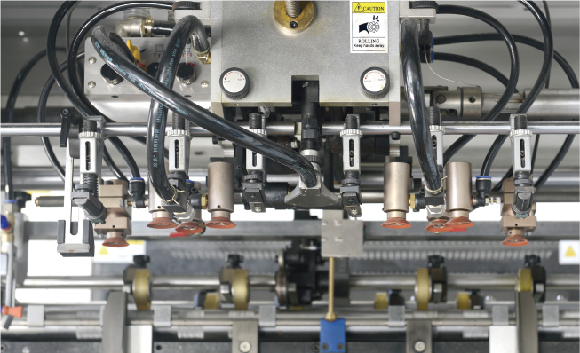

Zuführeinheit

Three pick up and four forward suck heads with angle adjustment to handle different kinds of materials.

Fütterungstisch

Synchronisiereinrichtung um die Bogenpositionierung während der Produktion manuell an die Vordermarke anzupassen, Bogenniederhalter (führt die Bögen an die Vordermarken).

Hot stamping section

Heating base with 20 heating zone each temperature adjustable individually for efficient and accurate temperature control.

Foil advancing unit

Three sets of longitudinal foil advancing shafts and two sets of lateral foil advancing shafts are driven by servo motors individually programmable for short and long foil stepping.

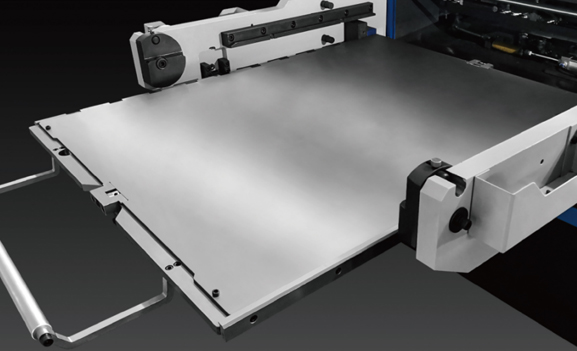

Platteneinstellung

5mm hardened stamping plate or 3.5mm + 1.5mm sandwich stamping plate on top of 15mm precision ground supporting base plate with +/-0.9mm micro adjustment in both running and cross direction for quick set up and easy make ready.

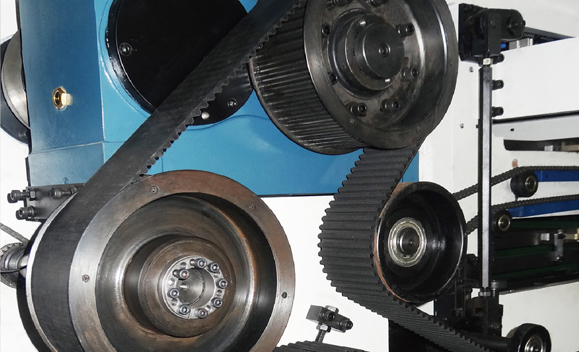

Drehmomentbegrenzer

Die hochpräzise intermittierende Segmentierung von Taiwan gewährleistet eine hohe Positionsgenauigkeit bei Langzeitnutzung.

Der Drehmomentbegrenzer von Taiwan kann durch seine sensible Grenzschutzleistung präzise vor künstlichen Betriebsunfällen schützen und so die Sicherheit von Mensch und Maschine gewährleisten.

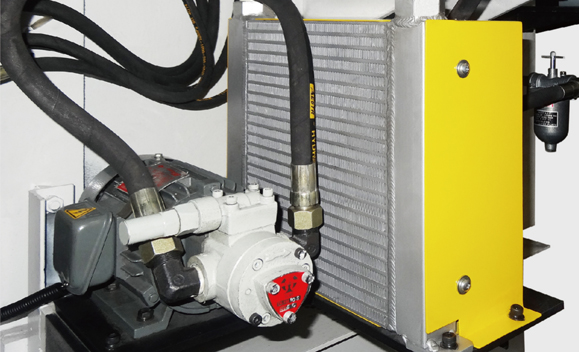

Hauptmotorschmiersystem

In Taiwan hergestelltes automatisches Kühlzirkulationssystem für Ölpumpen, um die Schmierung des Hauptmotors bei hoher Geschwindigkeit über einen langen Zeitraum sicherzustellen.

Ausgestattet mit Öldruckmesser und Öldruckalarmvorrichtung.

Liefereinheit

Automatic delivery with non–stop curtain. This curtain moves into the delivery to catch the arriving sheets during the pile exchange.two blowers for paper collection can ensure neat collection of thin and thick papers.

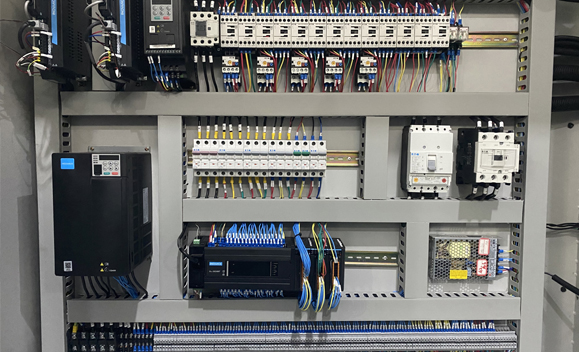

Elektrische Einheit

Verwendet elektrische Komponenten weltbekannter Marken (MOELLER\OMRON) für bessere Leistung und rechtzeitigen, lokalen Kundendienst und Wartung.

Deutschland Vakuumpumpe

Ölfreies Gebläse und Vakuumpumpe von Becker aus Deutschland.

Automatisches Schmiersystem

Verwenden Sie ein konzentriertes automatisches Schmiersystem, um sicherzustellen, dass die angetriebenen Teile besser funktionieren.

Machine Parameters

| Modell | MHK-820T |

|---|---|

| Maximale Blattgröße | 820×600mm |

| Minimale Blattgröße | 310×260mm |

| Maximale Schnittgröße | 800×580mm |

| Max. Hot Stamping Size | 800×600mm |

| Minimaler Greiferrand | 9-17 mm |

| Größe des inneren Chase | 910×605mm |

| Lagersortiment | Papier: von 80 bis 2000g/m2, 0,1~2mm, Wellpappe: bis 4mm |

| Stanzgenauigkeit | ≤±0,075 mm |

| Common Stamping Accuracy | ≤±0,075 mm |

| Hologram Positioning Stamping Accuracy | ≤±0.075mm(optional) |

| Max. Stanzkraft | 200T |

| Max. Arbeitsgeschwindigkeit | 7000s/h (Die cutting);7000s/h (Hot stamping) |

| Max. Stapelhöhe im Anleger | 1500mm(With wooden pallet) |

| Max. Stapelhöhe | 1300mm(With wooden pallet) |

| Max. Gold Foil Diameter | 250mm Horizontal, 200mm Vertical |

| Electric-heated System | 20 temperature ranges, 40-180℃ is adjustable |

| Foil Width | 20-780mm |

| Maschinenabmessungen | 6579×3826×2388mm(L×W×H) (L: paper prepared track included, W: platform included) |

| Nettogewicht der Maschine | 14.5ton |

| Main motor wattage | 11w |

| Leistung bei Volllast | 52kw |

| Luftbedarf | Druck: 0,6–0,7 MPa, Durchfluss: ≥ 0,37 m³/min |

Bewertungen

Es gibt noch keine Bewertungen.