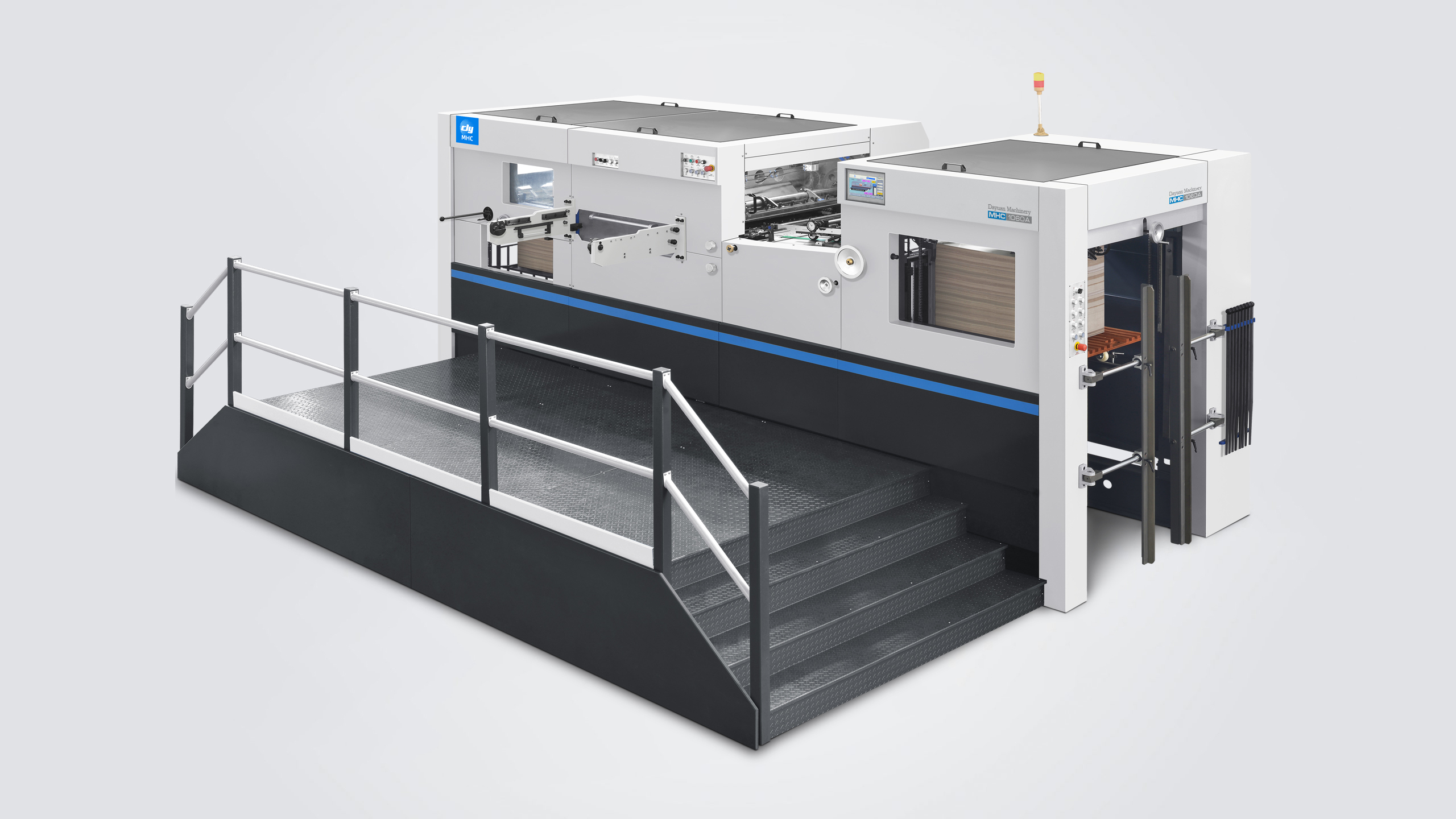

MHC 1060A/1080A Automatic Die Cutting And Creasing Machine(Heavy duty)

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Product Description

Introduction to the MHC 1060A/1080A Automatic Die Cutting and Creasing Machine (Heavy Duty)

The MHC 1060A/1080A Automatic Die Cutting and Creasing Machine (Heavy Duty) is a cutting-edge solution designed to meet the demanding needs of the packaging and printing industries. This robust machine combines advanced technology with superior performance to ensure high precision, efficiency, and reliability, making it an essential asset for high-volume production environments.

Hauptmerkmale

Hohe Präzision und Genauigkeit

The MHC 1060A/1080A delivers millimeter-perfect die cutting and creasing, ensuring detailed and exact specifications for a wide range of applications. This high level of precision reduces material waste and guarantees superior product quality, essential for maintaining high production standards.

Heavy-Duty Performance

Built to withstand intensive use, the MHC 1060A/1080A is engineered with durable materials and advanced technology. Its robust construction ensures long-term reliability and consistent performance, even under the most demanding production conditions.

Hochgeschwindigkeitsleistung

Designed for high-speed operations, the MHC 1060A/1080A significantly boosts productivity. Its advanced technology and sturdy construction enable it to handle large-scale production efficiently, meeting tight deadlines without compromising accuracy or quality.

Erweiterte Automatisierung

The MHC 1060A/1080A features comprehensive automation, including automatic feeding, die cutting, and creasing functionalities. This integrated approach streamlines the production process, reducing manual labor and increasing operational efficiency.

Benutzerfreundliches Interface

Ein intuitives Touchscreen-Display ermöglicht eine einfache Einrichtung und Echtzeitüberwachung. Diese benutzerfreundliche Oberfläche minimiert den Lernaufwand für die Bediener und gewährleistet einen reibungslosen und effizienten Betrieb.

Vorteile

- Verbesserte Effizienz: The combination of high-speed operations and advanced automation significantly boosts productivity, making it suitable for large-scale production runs.

- Verbesserte Sicherheit: Equipped with emergency stop buttons and protective guards, the MHC 1060A/1080A ensures a safe working environment, adhering to the highest industry standards.

- Vielseitigkeit: Ideal für verschiedene Anwendungen, darunter Verpackungen, Etiketten, Beschilderungen und benutzerdefinierte Druckmaterialien. Seine Präzision und Effizienz machen ihn zu einem wertvollen Werkzeug für Unternehmen, die ihre Produktionsprozesse optimieren und große Mengenanforderungen erfüllen möchten.

Anwendungen

The MHC 1060A/1080A is perfect for a wide range of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and heavy-duty capabilities make it a valuable tool for businesses aiming to optimize their production processes and meet high-volume demands.

Auswirkungen auf die Branche

By integrating the latest technology and automation, the MHC 1060A/1080A Automatic Die Cutting and Creasing Machine sets a new standard in the packaging and printing industries. Its innovative design and operational efficiency help businesses achieve higher productivity and better quality, positioning them for success in competitive markets.

Abschluss

The MHC 1060A/1080A Automatic Die Cutting and Creasing Machine (Heavy Duty) represents a significant advancement in die cutting and creasing technology. With its precision, speed, and integrated automation, this machine is designed to meet the rigorous demands of modern manufacturing. Investing in the MHC 1060A/1080A means embracing a future of increased productivity and superior quality, helping businesses stay ahead in a rapidly evolving industry.

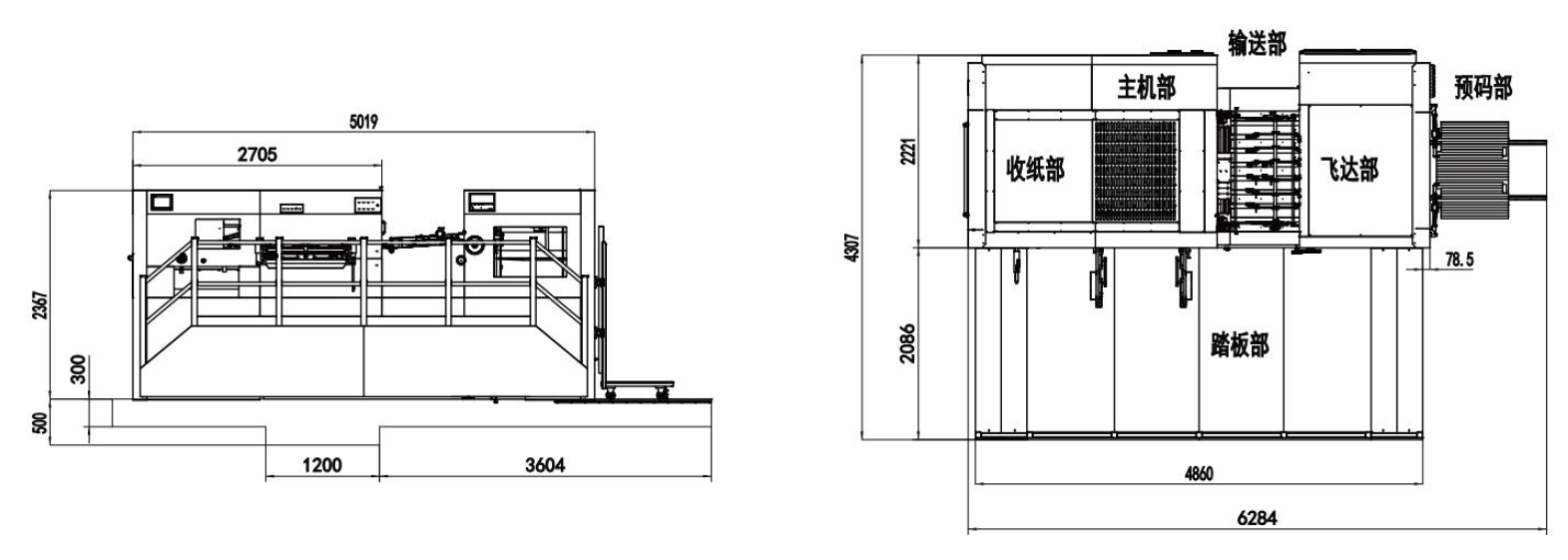

Zeichnung

Teilweise Einführung

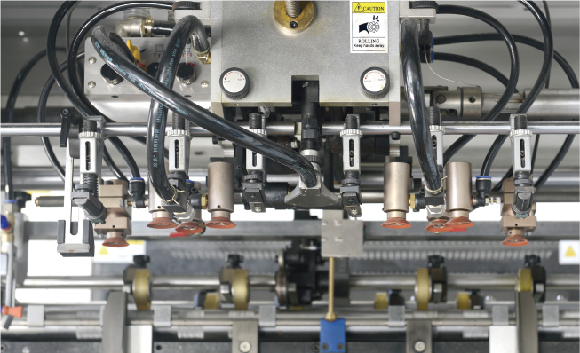

Feeder unit

Four pick up and four forward suck heads with angle adjustment to handle different kinds of materials.

Feeding table

Synchronizing device to adjust the sheet positioning to the front lay by hand during production,Sheet hold-down device (guiding the sheets to the front lays).

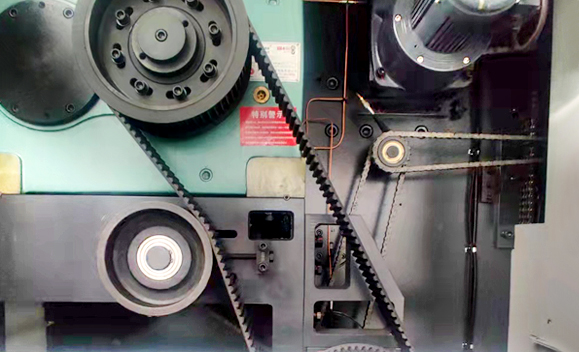

Zahnriemengetriebenes Gerät

Die hochpräzise intermittierende Segmentierung von Taiwan gewährleistet eine hohe Positionsgenauigkeit bei Langzeitnutzung.

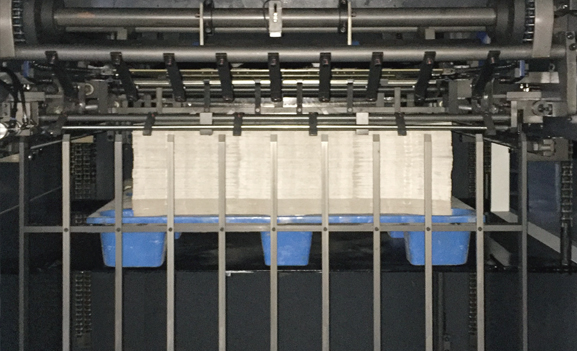

Papierauffangeinheit

Automatische Ausgabe mit Non-Stop-Vorhang. Dieser Vorhang bewegt sich in die Ausgabe, um die ankommenden Blätter während des Stapelwechsels aufzufangen. Zwei Gebläse zum Papiersammeln sorgen für ein sauberes Sammeln von dünnem und dickem Papier.

Automatisches Schmiersystem

Verwenden Sie ein konzentriertes automatisches Schmiersystem, um sicherzustellen, dass die angetriebenen Teile besser funktionieren.

Machine Parameters

| Modell | MHC-1060A |

|---|---|

| Maximum Sheet Size | 1060×760mm |

| Minimum Sheet Size | 400×350mm |

| Maximum Cutting Size | 1050×750mm |

| Minimum Gripper Margin | 9-17mm |

| Inner Chase Size | 1100×790mm |

| Lagersortiment | Paper: from 90 to 2000g/m2, 0.1~2mm, corrugated board: up to 4mm |

| Die Cutting Accuracy | ≤±0.1mm |

| Max.die Cutting Force | 600T |

| Max.working Speed | 7500s/h |

| Max. Feeder Pile Height | 1600mm (With wooden pallet) |

| Max. Delivery Pile Height | 1400mm (With wooden pallet) |

| Machine Dimensions | 6284×4307×2367mm (L×W×H) (L: paper prepared track included, W: platform included) |

| Net Weight of Machine | 18.5T |

| Main motor wattage | 15 kW |

| Full Load Wattage | 21kw |

| Air Requirement | Pressure: 0.6~0.7Mpa, Flow: ≥0.37m3/min |

| NOTIZ | Gleiche Features werden in der Tabelle als eins geschrieben. |

Bewertungen

Es gibt noch keine Bewertungen.