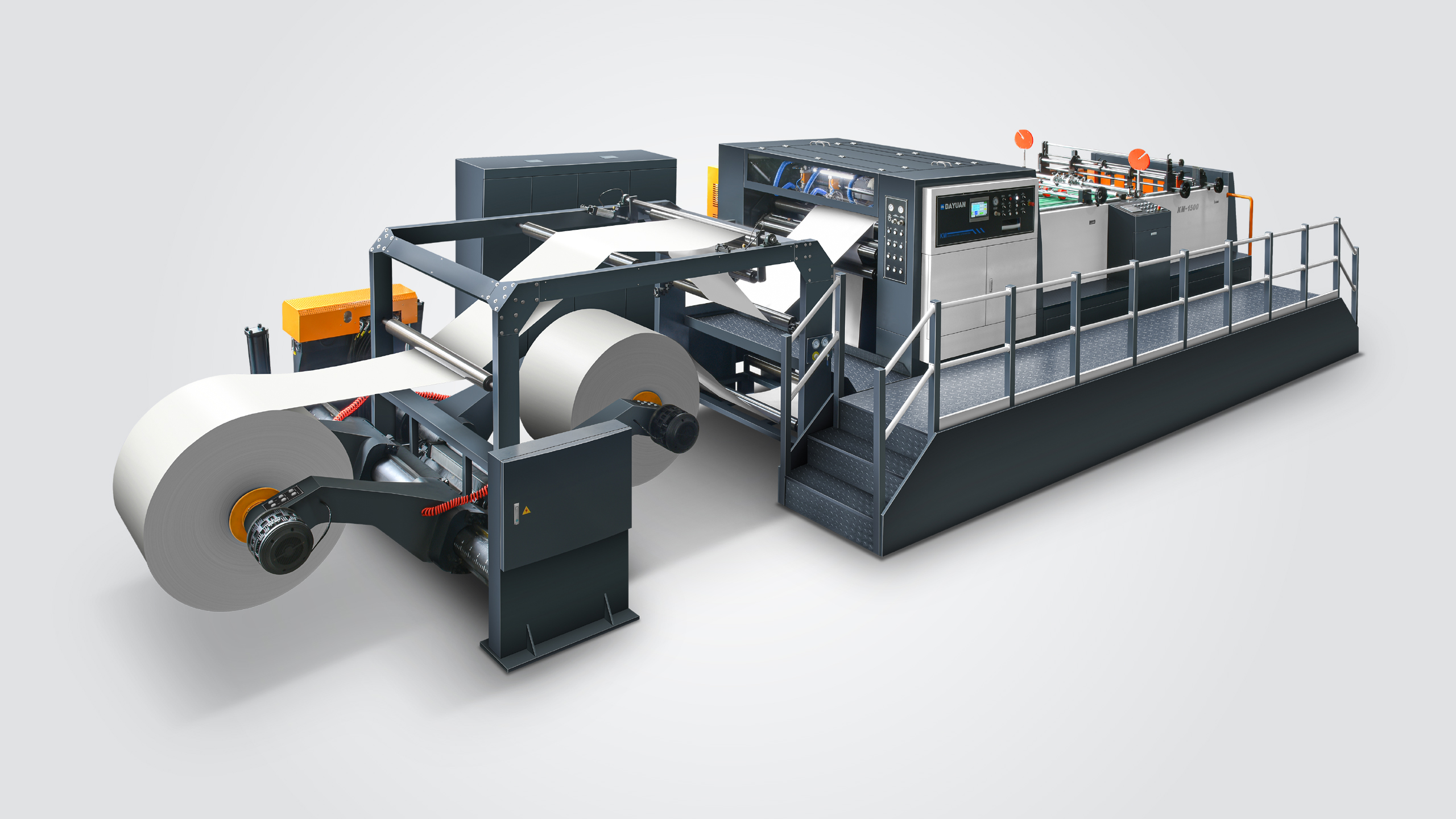

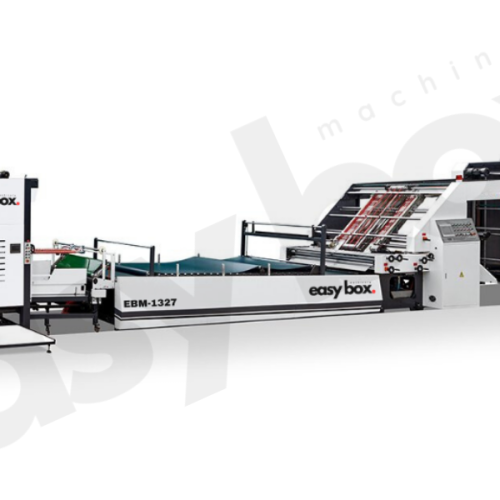

KM-1100/1500/1700 Servo-Präzisions-Doppelhelix-Hochgeschwindigkeits-Bogenschneidemaschine

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 WhatsApp Chat

Product Description

KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine: Precision and Efficiency in Industrial Cutting

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine is designed to meet the demanding needs of various industries requiring high-speed and high-precision sheet cutting. Combining advanced servo technology with a double-helix cutting mechanism, these machines offer unparalleled accuracy, speed, and reliability.

Hauptfunktionen und Vorteile

Fortschrittliche Servo-Präzisionstechnologie

The KM series machines are equipped with state-of-the-art servo motors, providing precise control over the cutting process. This advanced technology ensures high-speed operations with exceptional accuracy, making these machines ideal for industries that demand meticulous precision.

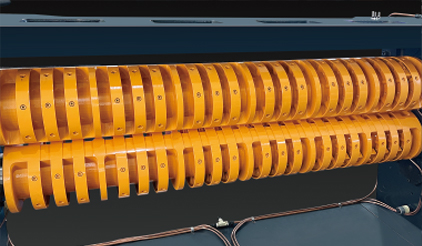

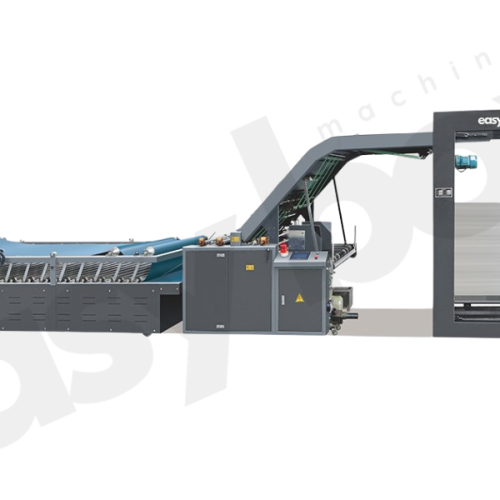

Double-Helix Cutting Mechanism

The innovative double-helix cutting mechanism ensures smooth and clean cuts, significantly reducing the risk of jagged edges or imperfections. This feature enhances the overall quality of the finished product and improves the efficiency of the cutting process.

Hochwertige Konstruktion

Constructed from high-quality materials and featuring high-tension casting, the KM series machines are built for durability and stability. This robust construction ensures that the machines can handle heavy-duty tasks efficiently and consistently.

Vier-Wellen-Kegelrad-Struktur

The four-shaft bevel wheel structure guarantees steady operation, excellent cutting performance, and low noise levels. This design is particularly suited for various industrial environments where precision and reliability are paramount.

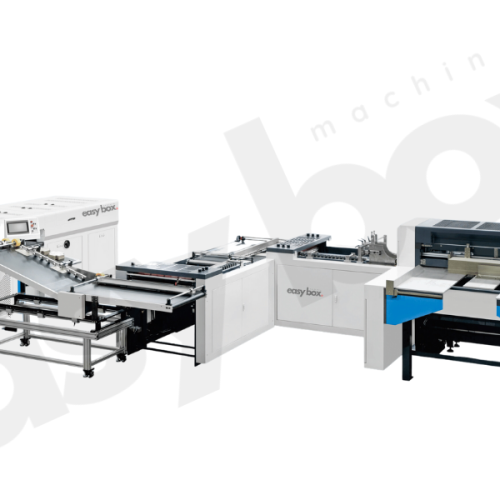

Schneidesystem mit automatischer Positionierung

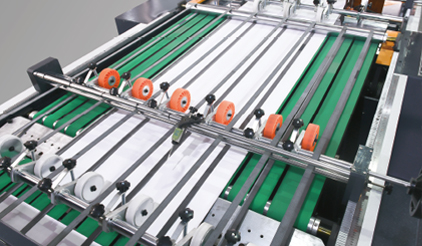

The auto positioning slitting system is an advanced feature of the KM series. This system automatically adjusts the position of the slitting blades, ensuring consistent and accurate cuts every time. This automation reduces setup time and minimizes human error, leading to increased productivity.

Papiervorpressgerät

The paper pre-press device ensures proper alignment and pressing of materials before cutting. This feature is crucial for achieving high-quality cuts and preventing misalignment or errors during the cutting process.

Gerät zur dreimaligen Abgabe (keine Abdrucklinie)

Das Dreifach-Liefergerät verhindert Abdrucklinien auf dem fertigen Produkt und sorgt für ein sauberes und professionelles Erscheinungsbild. Diese Funktion ist besonders nützlich für Anwendungen, die hohe ästhetische Standards erfordern.

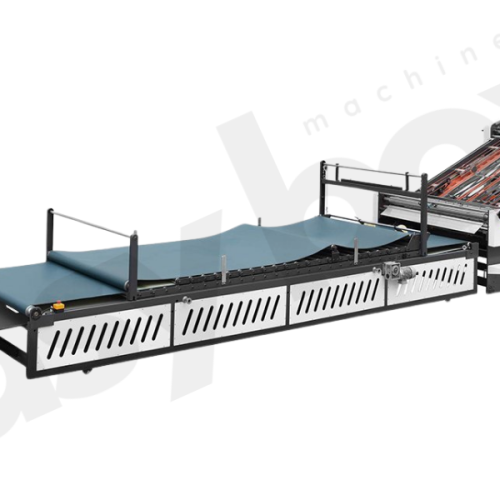

Pneumatische Hebevorrichtung für Auffangbretter

Die pneumatische Hebevorrichtung der Auffangplatte verbessert den Bedienkomfort, indem sie ein reibungsloses und effizientes Auffangen geschnittener Blätter ermöglicht. Dieser pneumatische Mechanismus reduziert die manuelle Handhabung und erhöht den Bedienerkomfort und die Produktivität.

Anwendungen in verschiedenen Branchen

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machines are suitable for a wide range of industries. Their precision cutting capabilities make them ideal for:

- Drucken: Gewährleistet hochwertige und präzise Schnitte für Druckmaterialien.

- Verpackung: Ermöglicht präzises und effizientes Schneiden von Verpackungsmaterialien.

- Papierprodukte: Handhabung unterschiedlicher Papierblattarten mit hoher Präzision.

- Kommerzieller Druck: Verbesserung der Produktivität und Qualität im kommerziellen Druckbetrieb.

Technologischer Fortschritt

The KM series stands out for its integration of advanced technological features, including servo precision and double-helix cutting. These innovations streamline the cutting process, reduce downtime, and significantly increase output, making these machines a valuable asset for modern industrial operations.

Abschluss

The KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machines offer an exceptional combination of efficiency, precision, and advanced automation. Their robust construction, intelligent functions, and ease of operation make them an excellent investment for businesses looking to enhance their cutting operations. Whether for printing, packaging, or other paper products, the KM series machines deliver superior performance and reliability, meeting the high demands of today’s industrial environments.

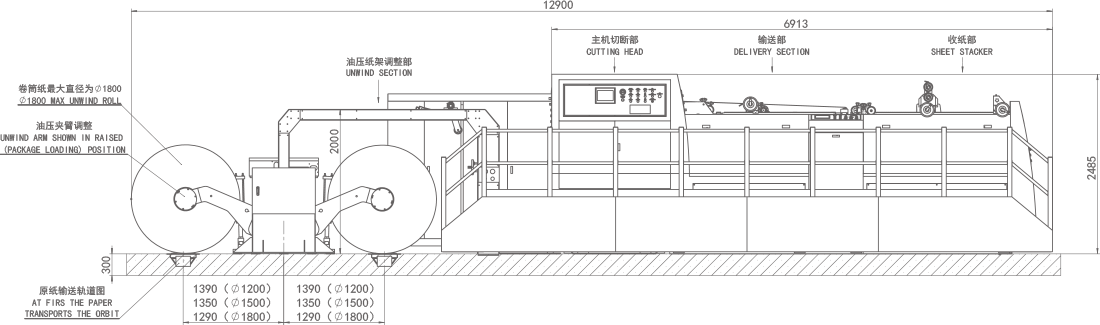

Zeichnung

Teilweise Einführung

Embedded double helix knife (Invention patent)

Slitting knifes (Optional)

Conveying unit

Machine Parameters

| Modell | KM-1100 |

|---|---|

| Modell zum Schneiden von Papier | Double rotary sheeter |

| Dicke des Schneidpapiers | 100-800gsm |

| Schnittlängenbereich | 450-1650mm |

| Cutting precision (1 roll) | Cutting length≤1000mm: ±0.1mm |

| Max. Schnittgeschwindigkeit | 330m/min |

| Max. Schnittgeschwindigkeit | 540cuts/min |

| Max. Spiraldurchmesser | 1500mm(KM-1100) |

| Max. Papierschnittbreite | 1100(45”)mm |

| Max. Papierstapelhöhe | 1300mm(KM-1100) |

| Die Anfrage für Luftkompressor | 0,8 MPa |

| Stromverbrauch | 380 V/220 V×50 Hz |

| G.W. (1 roll) | 16000kgs |

| Volllastleistung | 69kw |

| NOTIZ | Gleiche Features werden in der Tabelle als eins geschrieben. |

Bewertungen

Es gibt noch keine Bewertungen.