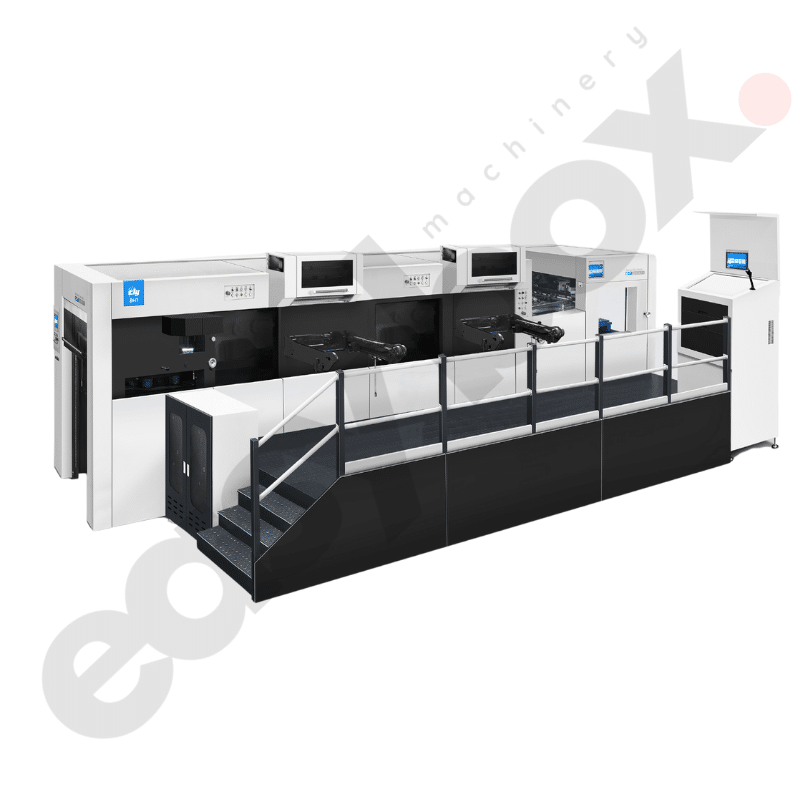

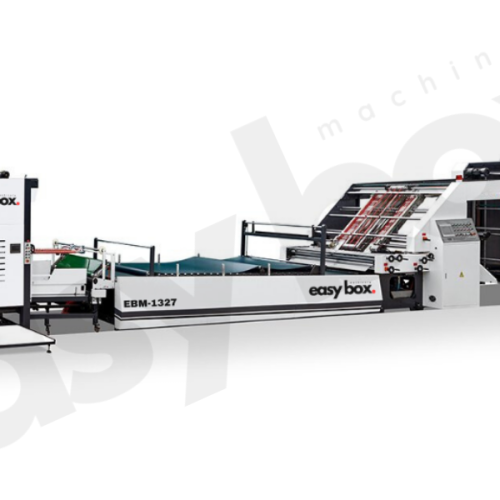

BHT 2S1060TT DUOPRESS Automatische Hochgeschwindigkeits-Doppelfolienpräge- und Stanzmaschine

(+86) 158 9968 3398 WhatsApp-Chat

Product Description

BHT 2S1060TT DUOPRESS Automatische Hochgeschwindigkeits-Doppelfolienpräge- und Stanzmaschine: Präzision und Effizienz für die moderne Fertigung

The BHT 2S1060TT DUOPRESS Automatic High Speed Double Foil Stamping and Die Cutting Machine is a top-of-the-line solution designed to meet the rigorous demands of contemporary manufacturing. Combining advanced double foil stamping with precise die cutting, this machine offers exceptional efficiency, accuracy, and reliability.

Hauptfunktionen und Vorteile

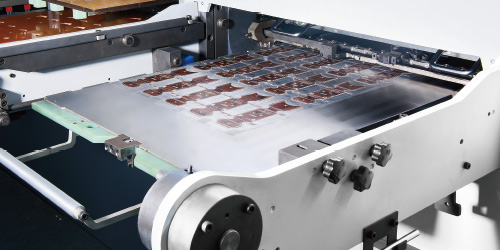

Double Foil Stamping System

The BHT 2S1060TT features a sophisticated double foil stamping system, allowing for intricate and high-quality foil designs on various materials. This dual stamping capability enhances the visual appeal of products, making it ideal for luxury packaging, high-end labels, and decorative items.

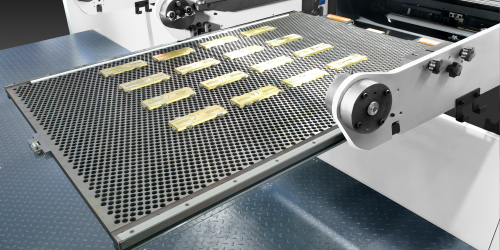

Precision Die Cutting

With its advanced die-cutting capabilities, the BHT 2S1060TT ensures clean and precise cuts every time. This precision is crucial for applications that demand detailed and flawless finishes, such as in the printing, packaging, and decorative industries.

Hochgeschwindigkeitsbetrieb

Designed for high-speed performance, the BHT 2S1060TT significantly increases production throughput. This capability is essential for large-scale production environments, ensuring the timely completion of substantial orders without compromising on quality.

Robust Construction

Built with high-quality materials, the BHT 2S1060TT is designed for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

Benutzerfreundliches Bedienfeld

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Safety Features

Safety is a top priority with the BHT 2S1060TT. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

Versatile Applications

The BHT 2S1060TT is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- Drucken: Delivering high-quality stamping and cutting for printed materials.

- Verpackung: Providing precise die-cutting and foil stamping for packaging materials.

- Labels and Tags: Creating detailed and attractive designs for labels and tags.

- Decorative Applications: Enhancing decorative items with intricate cuts and foil accents.

Verbesserte Produktivität

The integration of high-speed operation, double foil stamping, and die cutting functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

Technologische Fortschritte

The BHT 2S1060TT DUOPRESS stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

Abschluss

The BHT 2S1060TT DUOPRESS Automatic High Speed Double Foil Stamping and Die Cutting Machine offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the BHT 2S1060TT delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

Teilweise Einführung

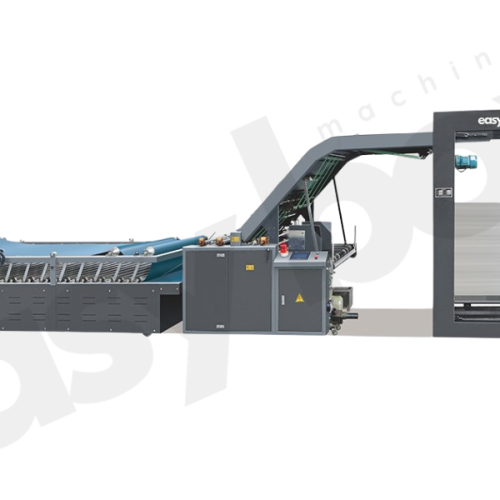

Zuführung

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

Doppelblechkontrolle

Ultraschall-Doppelbogenkontrolle ohne Berührung des Papiers, daher kratzfrei, zuverlässig und schnell einzurichten.

Greiferstange

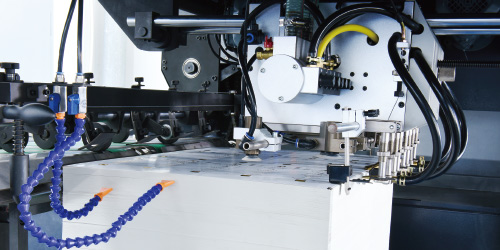

Gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

Hot stamping section

Max stamping pressure up to 600 tons, which makes it able to achieve better 3D and exquisite effect on large format printing materials such as wine boxes and cigarette boxes.

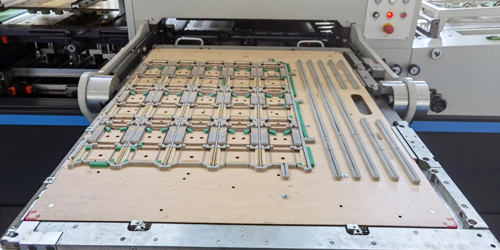

Platteneinstellung

5 mm gehärtete Schneidplatte oder 4+1 mm Sandwichplatte auf einer 15 mm starken, präzisen Kunststoff-Stützplatte mit Mikroeinstellung von +/- 0,9 mm für schnelles Aufstellen und einfaches Einrichten.

Form-Schnellverschluss

Verwenden Sie ein Mittelliniensystem und eine Schnellverriegelung, um Rüstzeit zu sparen.

Deutschland Vakuumpumpe

Ölfreies Gebläse und Vakuumpumpe von Becker aus Deutschland.

Automatisches Schmiersystem

Verwenden Sie ein konzentriertes automatisches Schmiersystem, um sicherzustellen, dass die angetriebenen Teile besser funktionieren.

Machine Parameters

| Modell | BHT-2S1060TT |

|---|---|

| Function | 1. hot stamping+hot stamping |

| Lagersortiment | Papier: von 80 bis 2000g/m2, 0,1~2mm, Wellpappe: bis 4mm |

| Maximale Blattgröße | 1060×760mm |

| Minimale Blattgröße | 400×350mm |

| Größe des inneren Chase | 1080×770mm |

| Maximale Schnittgröße | 1060×745mm |

| Maximum Stamping Size | 1060×740mm |

| Minimaler Greiferrand | 9~17mm |

| Mindestbreite von Doppelschnitten | 5 mm |

| Stanzgenauigkeit | ≤±0,075 mm |

| Stamping Accuracy | ≤±0,075 mm |

| Max. Stanzkraft | 600ton + 600ton |

| Max. Arbeitsgeschwindigkeit | 7200s/h |

| Maximum Pile Height at Feeder-Normal Mode | 1800 mm |

| Maximum Pile Height at Feeder-Non-stop Mode | 1520mm |

| Maximale Stapelhöhe bei Lieferung | 1580mm |

| Max.gold Foil Diameter | Φ250mm Longitudinal, Φ200mm Transversal |

| Electric-heated System | 20 Heating zones, 40~180℃ Adjustable |

| Foil Width | 20~1060mm |

| Press1 Foil Advance Shafts | 3 Longitudinal + 2 Transversal (Optional) |

| Press2 Foil Advance Shafts | 3 Longitudinal + 2 Transversal (Optional) |

| Maschinenabmessungen (L×B×H) | 9683×4708×2900mm |

| Machine Dimensions (Including Die Preloader) (L×W×H) | 9683×5608×2900mm |

| Nettogewicht der Maschine | 47000kg |

| Leistung bei Volllast | 114KW |

| Luftbedarf | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

Bewertungen

Es gibt noch keine Bewertungen.