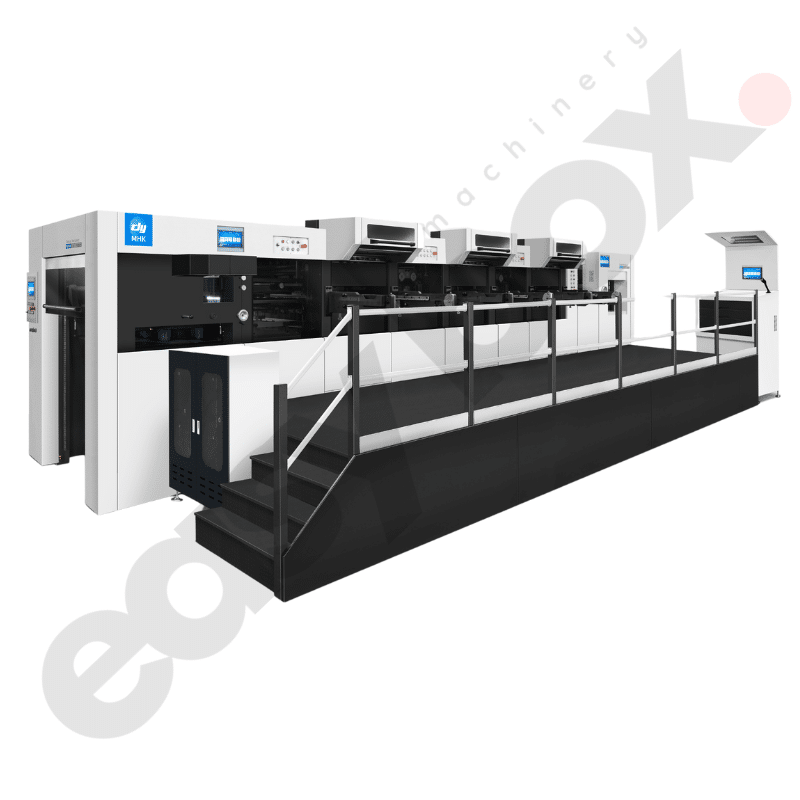

آلة MHK 3S1050TTTC TRIOPRESS الأوتوماتيكية عالية السرعة للختم الساخن والقطع بالقالب مع التجريد

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 دردشة واتساب

Product Description

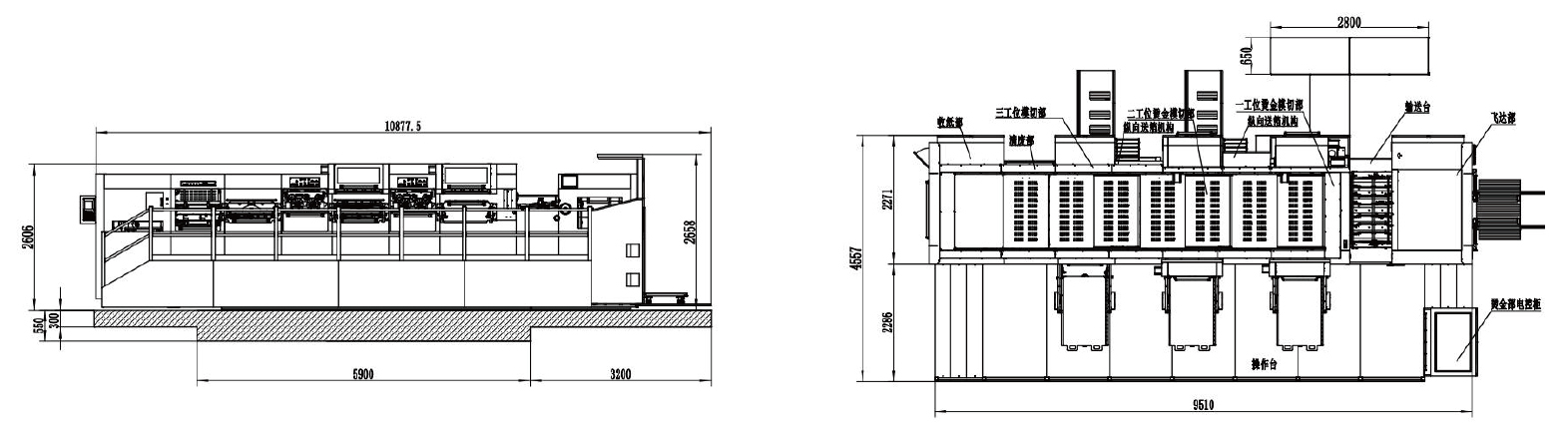

رسم

MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping: Superior Precision and Efficiency

The MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping is an advanced solution designed to meet the rigorous demands of modern post-press operations. By integrating multiple processes into a single seamless operation, this machine offers exceptional precision, efficiency, and reliability.

الميزات والفوائد الرئيسية

إمكانية تنفيذ عمليات متعددة بمرور واحد

The MHK 3S1050TTTC TRIOPRESS can perform multiple processes in one pass, significantly enhancing production efficiency and reducing labor costs. The machine’s capabilities include:

- Hot Stamping + Hot Stamping + Hot Stamping: Achieve intricate and high-quality triple foil designs in a single pass.

- الختم الساخن + الختم الساخن + النقش العميق: Combine double foil stamping with deep embossing for enhanced texture and detail.

- Hot Stamping + Hot Stamping + Die Cutting: Integrate double foil stamping with precise die cutting for a streamlined process.

- Hot Stamping + Deep Embossing + Die Cutting: Enhance products with foil stamping, deep embossing, and die cutting in one operation.

- Deep Embossing + Deep Embossing + Deep Embossing: Achieve multiple deep embossing effects for superior texture and detail.

- الختم الساخن + الختم الساخن + القطع بالقالب + التجريد: Perform double foil stamping, die cutting, and efficient stripping in a single seamless operation.

- الختم الساخن + النقش العميق + القطع بالقالب + التجريد: Combine foil stamping, deep embossing, die cutting, and stripping for high-quality finishes.

- النقش العميق + النقش العميق + القطع بالقالب + التجريد: Integrate multiple deep embossing processes with die cutting and stripping for superior results.

الدقة والكفاءة

The MHK 3S1050TTTC TRIOPRESS excels with its ability to accurately register multiple processes in one pass, a capability that traditional machines and duopress machines often cannot match. This precision ensures high-quality results and maximizes production efficiency.

بناء وتصميم قوي

Constructed from high-quality materials, the MHK 3S1050TTTC is built for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

واجهة سهلة الاستخدام

تتميز الماكينة بواجهة مستخدم سهلة الاستخدام، مما يسمح للمشغلين بإعداد وتعديل المعلمات ومراقبة عملية الإنتاج واستكشاف المشكلات وإصلاحها بسهولة. يعمل هذا التصميم سهل الاستخدام على تعزيز الإنتاجية وتقليل منحنى التعلم للمشغلين الجدد.

نظام تجريد فعال

يعمل نظام التجريد الفعال على إزالة المواد المهدرة تلقائيًا، مما يبسط عملية الإنتاج ويقلل الحاجة إلى التدخل اليدوي. تعمل هذه الميزة على زيادة الكفاءة، وضمان بيئة إنتاج أنظف، وتعزيز الجودة الشاملة للمنتجات النهائية.

ميزات السلامة

Safety is a top priority with the MHK 3S1050TTTC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

تطبيقات متعددة الاستخدامات

The MHK 3S1050TTTC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- الطباعة: تقديم خدمات ختم ونقش وقطع عالية الجودة للمواد المطبوعة.

- التغليف: توفير خدمات القطع الدقيق، وختم الرقائق، وتجريد مواد التغليف.

- العلامات والعلامات: إنشاء تصميمات مفصلة وجذابة للملصقات والعلامات.

- التطبيقات الزخرفية: تعزيز العناصر الزخرفية باستخدام القطع المعقدة واللمسات المعدنية والنحت.

زيادة الإنتاجية

The integration of high-speed operation, triple hot stamping, deep embossing, die cutting, and stripping functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

التقدم التكنولوجي

The MHK 3S1050TTTC TRIOPRESS incorporates advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

خاتمة

The MHK 3S1050TTTC TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine with Stripping offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their post-press processes. Whether for printing, packaging, or decorative applications, the MHK 3S1050TTTC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

مقدمة جزئية

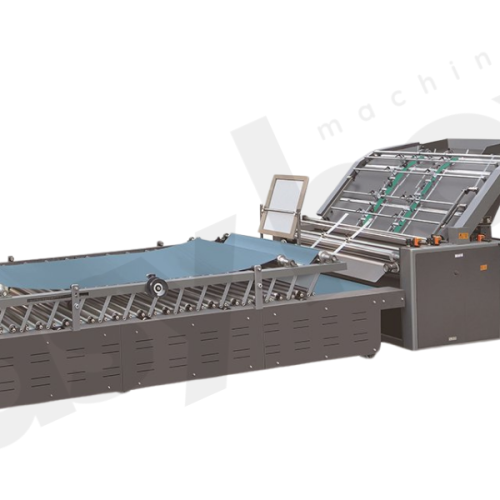

وحدة التغذية

أربعة رؤوس التقاط وأربعة رؤوس شفط أمامية مع إمكانية تعديل الزاوية للتعامل مع أنواع مختلفة من المواد.

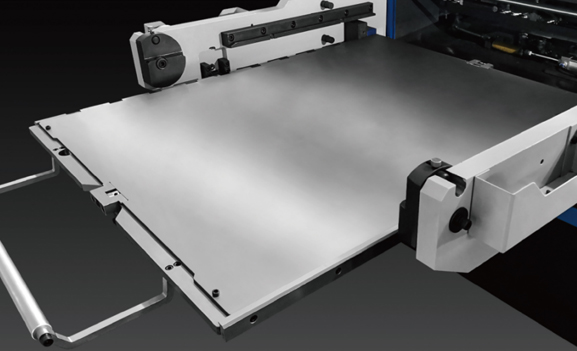

طاولة التغذية

جهاز مزامنة لضبط وضع الورقة إلى الوضع الأمامي يدويًا أثناء الإنتاج، وجهاز تثبيت الورقة (توجيه الأوراق إلى الوضع الأمامي).

قسم الختم الساخن

قاعدة تسخين تحتوي على 20 منطقة تسخين يمكن تعديل درجة حرارة كل منطقة على حدة للتحكم في درجة الحرارة بكفاءة ودقة.

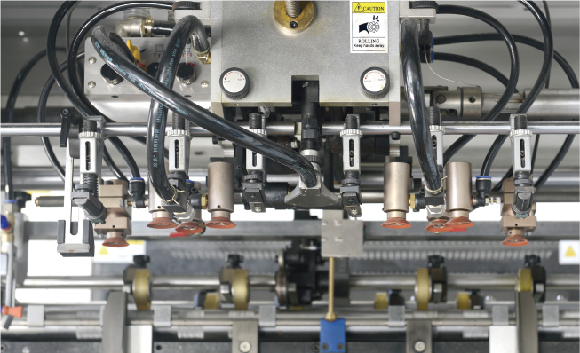

وحدة تقدم الرقائق

يتم تشغيل ثلاث مجموعات من أعمدة تقدم الرقاقة الطولية ومجموعتين من أعمدة تقدم الرقاقة الجانبية بواسطة محركات مؤازرة قابلة للبرمجة بشكل فردي للخطوات القصيرة والطويلة.

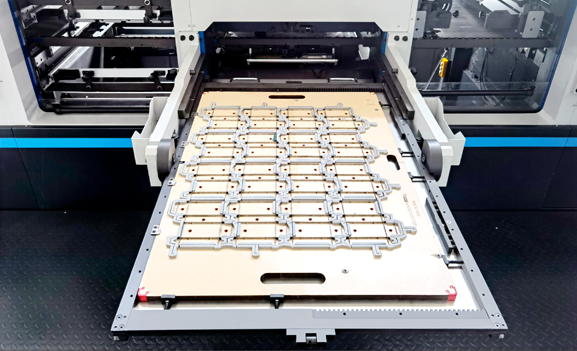

جهاز قفل سريع للقالب

اعتماد نظام خط الوسط وجهاز القفل السريع لتوفير وقت الاستعداد.

ضبط اللوحة

لوحة ختم مقواة 5 مم أو لوحة ختم شطيرة 3.5 مم + 1.5 مم فوق لوحة قاعدة داعمة أرضية دقيقة 15 مم مع تعديل دقيق +/- 0.9 مم في كل من اتجاه التشغيل والاتجاه العرضي للإعداد السريع والإعداد السهل.

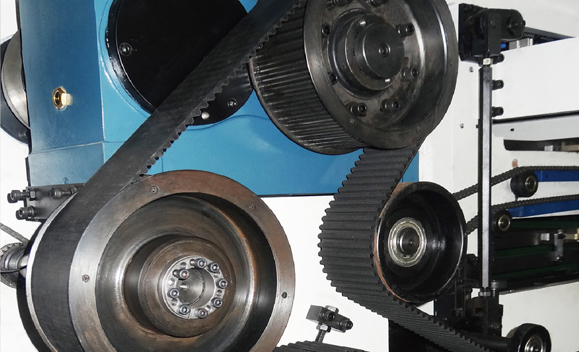

محدد عزم الدوران

تضمن التجزئة المتقطعة عالية الدقة من تايوان دقة موضعية عالية للاستخدام لفترة طويلة.

يمكن لمحدد عزم الدوران التايواني حماية حوادث التشغيل الاصطناعية بدقة لضمان سلامة الأشخاص والآلات من خلال أداء حماية الحد الحساس.

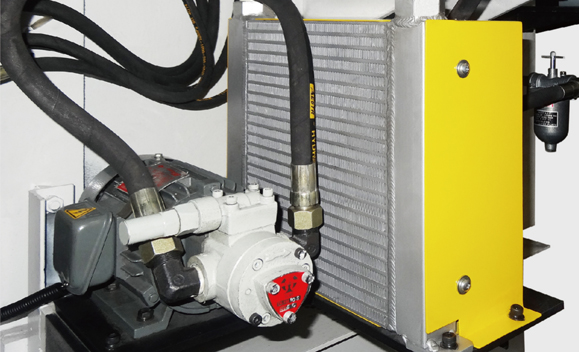

نظام تزييت المحرك الرئيسي

نظام تبريد مضخة الزيت الأوتوماتيكي المصنوع في تايوان لضمان تزييت المحرك الرئيسي بسرعة عالية لفترة طويلة.

مجهزة بمقياس ضغط الزيت وجهاز إنذار ضغط الزيت.

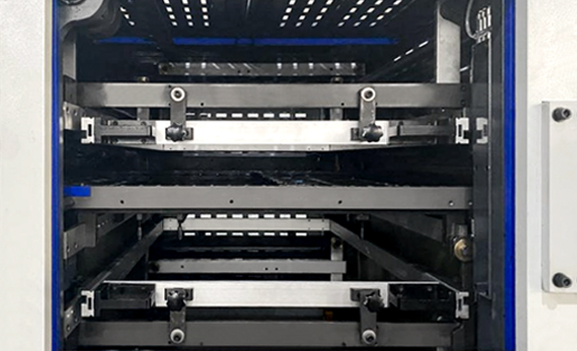

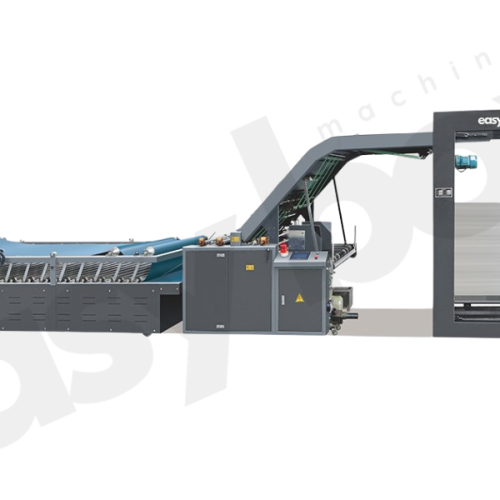

وحدة التجريد

اعتماد نظام خط الوسط، يمكن سحب إطار تركيب أداة التجريد العلوية والسفلية للخارج لإعداد المهمة وتجهيزها.

جهاز إزالة النفايات من حافة المقبض

نظام تجريد وإزالة حافة المقبض مع حزام ناقل لإزالة نفايات حافة المقبض جانبيًا إلى جانب القيادة.

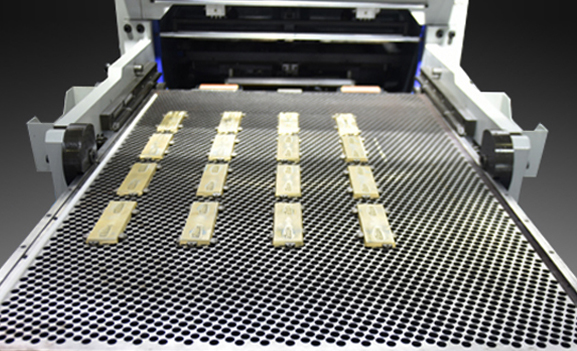

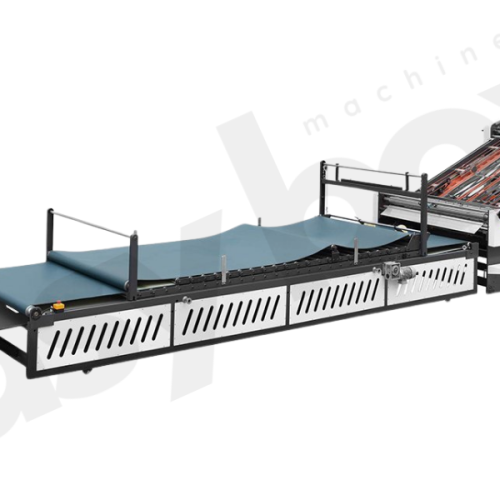

وحدة التوصيل

تسليم تلقائي بستارة مستمرة. تتحرك هذه الستارة إلى التسليم لالتقاط الأوراق القادمة أثناء تبادل الأكوام. يمكن لاثنين من النفخات لجمع الورق ضمان التجميع المنظم للأوراق الرقيقة والسميكة.

مضخة فراغ المانيا

منفاخ ومضخة تفريغ خالية من الزيت من ألمانيا Becker.

نظام التشحيم التلقائي

اعتماد نظام التشحيم التلقائي المركز للتأكد من أن الأجزاء المحركة تعمل بشكل أفضل.

Machine Parameters

| نموذج | MHK-3S1050TTTC |

|---|---|

| وظيفة | 1. hot stamping+hot stamping+hot stamping |

| Max.sheet size | 1050×750 مم |

| Min.sheet size | 400×360 مم |

| Max.die cutting size | 1040×720 مم |

| Max.hot stamping size | 1040×720 مم |

| Gripper margin | 9~17 ملم |

| Inner chase size | 1080×745mm |

| Stock range | 80~2000g/m2 Cardboard, 0.1~2mm Cardboard, ≤4mm Corrugated |

| Die cutting accuracy | ≤±0.075 مم |

| Common stamping accuracy | ≤±0.075 مم |

| Hologram positioning stamping accuracy | ≤±0.075 مم |

| Max.die cutting force | 600ton + 600ton + 600ton |

| Max.working speed | 6200s/h |

| Max.feeder pile height (wooden pallet included) | 1600 ملم |

| Max.delivery pile height (wooden pallet included) | 1400mm |

| Max.gold foil diameter | Φ250mm Longitudinal, Φ200mm Transversal |

| نظام التدفئة الكهربائية | 20 Heating zones, 40~180℃ Adjustable |

| Foil width | 20~1020 ملم |

| Press 1 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Press 2 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Press 3 foil advance shafts | 3 Longitudinal+2 Transversal (Optional) |

| Servo motor power | 15KW/15KW/15KW |

| Full load wattage | 160KW |

| Air requirement | Air pressure: 0.6~0.7Mpa, Flow rate: >1m3/min |

| البعد | 10800×4586×2565mm |

| Dimension (die preloader included) | 10800×5086×2565mm |

| وزن | 47T |

المراجعات

لا توجد مراجعات بعد.